Replacing plastic looks hard, but alternatives to fossil fuel materials are on the rise.

TROY FARAH - 1/20/2020

Enlarge / Spilled garbage on the beach off the Black Sea in Bulgaria.

iStock / Getty Images

The English metallurgist Alexander Parkes never saw the widespread realization of his spectacular 19th-century invention, celluloid, the first plastic. While a revolutionary breakthrough, Parkesine, as it was called, was expensive and brittle. It was used in objects like buttons and combs, but ultimately quality control issues led Parkes’ company to bankruptcy in 1868 just 12 years after the discovery.

Parkesine, however, was also the first bioplastic—a plastic made from renewable plant material instead of fossil fuels. And today with the environmental impact of plastics increasingly on the public mind, bioplastics are making a big comeback. They’re proposed by some as the solution to beaches deluged with plastic and fish bellies stuffed with bottle caps. And perhaps bioplastics can replace oil-based polymers that commonly trash oceans with materials that can break down more easily and would protect a planet already smothered in these resilient substances

Bioplastic items already exist, of course, but whether they’re actually better for the environment or can truly compete with traditional plastics is complicated. Some bioplastics aren’t much better than fossil fuel-based polymers. And for the few that are less injurious to the planet, cost and social acceptance may stand in the way. Even if widespread adoption of bioplastics occurs down the line, it won’t be a quick or cheap fix. In the meantime, there is also some pollution caused by bioplastics themselves to consider. Even if bioplastics are often less damaging than the status quo, they aren’t a flawless solution.

So, could saving the planet simply come down to some design decisions? We may soon find out. Market demand for bioplastics is ballooning, with global industrial output predicted to reach 2.62 million tonnes annually by 2023, according to the Berlin-based trade association European Bioplastics. Currently, that’s only one percent of the 335 million tonnes of conventional plastics produced every year. But the European Commission, in its 2018 Circular Economy Action Plan, detailed bioplastics research as part of their strategy to drive investment in a climate-neutral economy.

“Sometimes we like to see the word ‘green,’ but we always should have appropriate awareness about the material we are dealing with,” says Federica Ruggero, an environmental engineer at the University of Florence, Italy. “It's a very good starting point in the production chain to have these new materials that can substitute plastics … but it's also important to consider the waste that comes from this material.”

To put it plainly: not all bioplastics are created equal. So which ones may be key to a genuinely “greener” future? In 2020, five candidates seem to be rising to the eco-friendly top.

Bioplastic basics

Bioplastics have come a long way since the days of Alexander Parkes. Today, these materials can be made from many renewable resources: cornstarch, beet sugar, kiwi skins, shrimp shells, wood pulp, even mangos and seaweed. They can function approximately the same as materials like vinyl or PET, the plastic most commonly used in drink bottles.

But if these polymers don’t actually have a smaller carbon footprint than plastics refined from petroleum, they may only be another example of greenwashing, a misleading marketing tactic more about image than outcomes. That’s one of the problems with the fact that there isn’t yet a universal definition of “bioplastic.”

“Bioplastic is basically anything that people like to call bioplastic,” says Dr. Frederik Wurm, a chemist at the Max Planck Institute for Polymer Research in Mainz, Germany. The term can currently mean a material made from fossil fuels that can biodegrade, such as PCL, a plastic used in packaging and drug delivery.

Bioplastics can also be biobased and not biodegradable, like the PET bottles Coca-Cola made entirely from plants. But their end product is chemically identical to PET made from oil, so it can still take centuries to fully break down. In 2013, the Coca-Cola Company (considered by one environmental advocacy group as the “most polluting brand”) pledged to make all their bottles this way by 2020, but it later backpedaled to focus more on recycling, according to the The W all Street Journal. Greenpeace, the pro-environment non-profit, has said, “Plant bottles are not the answer.”

Additives mixed with conventional plastics to speed up biodegradation don’t seem to help either. Oxo-degradable products are standard plastics that are chemically treated to quickly fragment when exposed to sunlight and oxygen—but they don’t break down entirely. And because these plastics are otherwise no different from untreated versions, the microplastics they produce can still pose environmental hazards. The European Union is currently working to ban oxo-degradable plastics.

Generally, it appears the starting material is less important than what it’s turned into, making the ideal plastic both biobased and biodegradable. A few of these polymers do exist, but they disintegrate only under certain conditions.

Enlarge / A recycling factory worker in Thailand surveys the scale of plastics being disposed.

Pramote Polyamate / Getty Images

Polylactic Acid (PLA)

The most popular bioplastic is polylactic acid or PLA, which is typically made from fermented plant starches. PLA already sees widespread use, often as single-use cups labeled with something like “compostable in industrial facilities.”

FURTHER READING Making industrial chemistry green: catalysts, chemicals, and lifecycle

Therein lies the flaw: PLA only breaks down under ideal temperatures in industrial composts. In ocean water, where microorganism populations differ from landfills, PLA is as unlikely to fully disintegrate as a polyethylene plastic bag. Most home composts can’t manage PLA, and recycling it improperly can contaminate other salvageable plastics.

Polyhydroxybutyrate (PHB)

In 1926, French researcher Maurice Lemoigne found that by stressing out Bacillus megaterium, a bacteria much larger than E. coli, the microbe would produce polyhydroxybutyrate, or PHB. This can be used to make a plastic that, when it breaks down, becomes nothing but CO2, water, and organic biomass.

Unfortunately, few things are made of PHB because it’s up to 100 times more expensive to produce than other plastics, and cost is not predicted to drop soon. To get around this, scientists have tried genetically modifying plants to produce PHB just like fermenting bacteria, but so far those experiments haven’t been able to lower the price by much.

Polybutylene Succinate (PBS)

PBS was yet another accidental discovery, this time in 1863 by the Portuguese professor Agostinho Vicente Lourenço, who wasn’t fully aware of what he uncovered when he fermented sugar and mixed it with toxic ethylene glycol. PBS was rediscovered in the 1930s and made into biodegradable plastic, but it was too brittle and largely forgotten for decades. It was investigated once more in 1993 by a Japanese company called Showa Denko that began producing 3,000 tonnes per year under the trademark Bionolle. Their improved recipe made a much stronger polymer than previous attempts.

PBS is a useful substitute for propylene, the second most widely used plastic, and can be used for bags and as a replacement for the long sheets of mulch film used in agriculture. However, its complex synthesis produces a large amount of greenhouse gases, which may not make it all that much better for the environment.

In 2016, Showa Denko ceased making PBS, saying they couldn’t compete with the “harsh market environment for biodegradable plastics.” A few other companies, such as Dow Chemical and Mitsubishi Chemical Corp, still make it, however, and the market is slowly growing.

Hemp

Kevin Tubbs, founder of the Hemp Plastic Company, says his customers are united by one thing: “They carry a purple-passion hatred for what's happening with fossil fuel-based polymer. They're tired of swimming in it, walking in it, they're just tired of that. There's got to be a better solution out there.”

Tubbs believes that solution is hemp, the non-intoxicating cousin to Cannabis sativa, or marijuana. Hemp is a fibrous plant that has been used for many centuries as a textile, but it only became fully legal again in the United States in December 2018. A lot of hemp is processed for CBD, a medicinal chemical swept up in the latest wellness trend, but the stalks and leaves that are left over can be processed into all kinds of plastics.

This year, Tubbs anticipates making about 50 million tons of hemp plastic pellets that can be used on regular plastics equipment, such as 3D printers or injection molds, which makes the switch for manufacturers a little easier. Some of the hemp plastics are like PLA, able to break down into vegetable material at the end of its life under the right conditions. Other varieties are a blend of one-third hemp, one-third petroleum plastics. But even a small amount is impactful, in Tubbs’ view.

“We believe that every bit of it we use is raw fossil fuel we didn't use,” Tubbs says. “We don't see it as the end-all solution at all but … If we only did 10 percent of the market, that'd be better than we've done as a country since plastic was invented,” citing the fact that less than nine percent of plastic is recycled in the US.

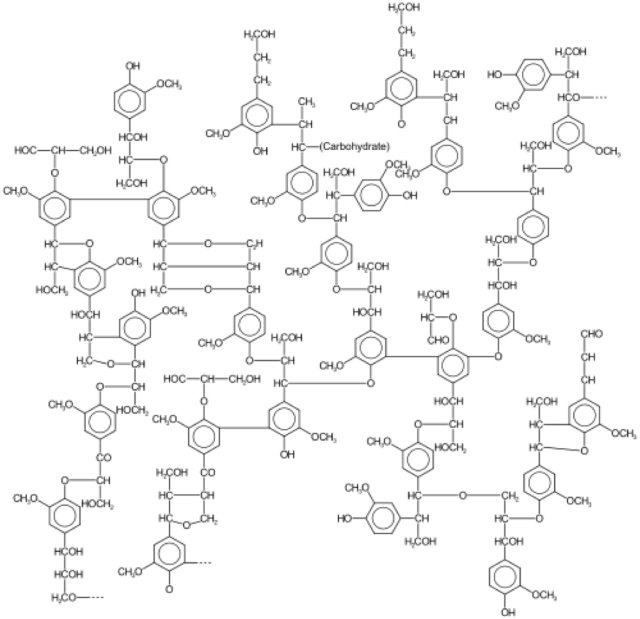

Enlarge / The complicated structure of lignin.

Wikimedia Commons

Lignin

Wurm says one of the most promising bioplastic candidates is lignin, a blackish biodegradable byproduct of paper manufacturing. Approximately 70 million tons of this stuff is pulped every year, but most of it is burned for fuel. It’s commonly said that “you can make anything you want out of lignin—except money,” as a 2017 review puts it before detailing how that is mostly no longer the case. These days lignin has become cost-effective for 3D printing or adhesives, and it can be plasticized or used to reinforce other bioplastics.

However, there is still a lack of investment in this market because it’s difficult or not worth the effort for companies to transition to using these materials. The cost of all bioplastics remains relatively high due to low oil prices.

“The biodegradable materials, regardless which kind of them [there] are, they cannot compete from the cost,” Wurm says, but adds that taxing less-environmentally friendly materials could help. “If the producers and the customers have to pay more for whatever gram of plastic, they might come up with lighter and more efficient ways of packaging things.”

Enlarge / All of these Lego pieces will now be made of sugarcane-derived polyethylene.

Lego\

A better bioplastic future

Designing an effective bioplastic needs to focus not only on what the material is made from, but how it will die and how quickly, even if it doesn’t end up in the preferred environment. But studies on the different outcomes of bioplastics can vary based on waste management standards, as Ruggero has studied, so it’s not always known how effectively bioplastics will break down in various environments.

“It’s very difficult to say that bioplastics [are] degradable in every environment,” Ruggero says. “That's why there are many different standards for the assessment of biodegradation.” Unifying those standards is crucial for making bioplastics actually sustainable, as well as not confusing consumers who may not realize what to do with these plastics at the end of their life cycle.

“That’s the challenge,” Wurm adds. “To develop a material which biodegrades in a reasonable timeframe and also is good food for the microorganisms that they can really take it up into the organism and do something, make biomass of it, and not just [release] it out as CO2 or methane.”

In the meantime, both Wurm and Ruggero suggest that a cultural shift in consumption attitudes is more important than finding plastic alternatives. Less overall plastic consumption should be a central focus. Some research suggests bioplastics may actually incentivize littering because people may think it will dissipate in nature. Waste management systems may also be unequipped to handle some of these materials, so they wind up in landfills anyway. An overhaul of this system would require better separation policies, as the EU has proposed.

“The fact that it is ‘bio’ doesn't exempt us from a rigorous collection of product,” Ruggero says. “The best way to reduce the problem of plastics is not always to change the different kind of plastic, which doesn't exploit the fossil fuels or is biodegradable.”

If bioplastics do become the norm, the energy required to grow and process the plant material also needs to be taken into consideration. However, one statistic suggests that even if all plastics were to switch to biobased sources, it would only make up five percent of all agricultural space. Nonetheless, places like South America may be at risk of greater deforestation to grow sugarcane used in plastics, for example, to say nothing of emissions from harvesting, refining, or shipping the bioplastics.

FURTHER READING New Lego pieces: Still hard on your feet, but easier on the planet

Current polymer supply chains—from extraction to production to recycling and end of life— are tightly wound for max efficiency. Adding new materials to the mix would be a costly endeavor that many large corporations may not even consider without more interest from the public or government oversight first. But overall, research and development of bioplastics is a step in the right direction, Ruggero says. “It's good to try to have new materials that are more environmentally friendly and you know how they are defined, but it's also important to consider them into the production chain."

A smarter plastic is only part of the equation, in other words. But as consumer demand increases, prices drop, and new technology emerges, bioplastics—whatever the term may eventually indicate—are likely to become more pervasive, especially as companies like Lego, IKEA, McDonald’s, and Nestlé explore multi-million dollar investments in this space.

“Everything was biodegradable when polymer chemistry actually started in the 19th century,” Wurm says, until chemists discovered stronger, cheaper alternatives using petroleum. “But we go back with modern chemistry. I think this is a strength that we can use what we learned on the way.”

Troy Farah is an independent journalist from Southwest California. His reporting on drug policy and science has appeared in WIRED, The Guardian, Discover Magazine, VICE and more. Previously at Ars, he shared the story of Dr. Aniru Conteh's battle against Lassa fever. He co-hosts the drug policy podcast Narcotica. Follow him on Twitter @filth_filler

MEANWHILE BIG OIL WANTS TO PRODUCE EVEN MORE PLASTICS

https://plawiuk.blogspot.com/2020/01/a-surge-of-new-plastic-is-about-to-hit.html

No comments:

Post a Comment