by Cell Press

A woman handling tableware made from bamboos and food industry waste.

Credit: Ruby Wallau/Northeastern University

Scientists have designed a set of "green" tableware made from sugarcane and bamboo that doesn't sacrifice on convenience or functionality and could serve as a potential alternative to plastic cups and other disposable plastic containers. Unlike traditional plastic or biodegradable polymers—which can take as long as 450 years or require high temperatures to degrade—this non-toxic, eco-friendly material only takes 60 days to break down and is clean enough to hold your morning coffee ordinner takeout. This plastic alternative is presented November 12 in the journal Matter.

"To be honest, the first time I came to the US in 2007, I was shocked by the available one-time use plastic containers in the supermarket," says corresponding author Hongli (Julie) Zhu of Northeastern University. "It makes our life easier, but meanwhile, it becomes waste that cannot decompose in the environment." She later saw many more plastic bowls, plates, and utensils thrown into the trash bin at seminars and parties and thought, "Can we use a more sustainable material?"

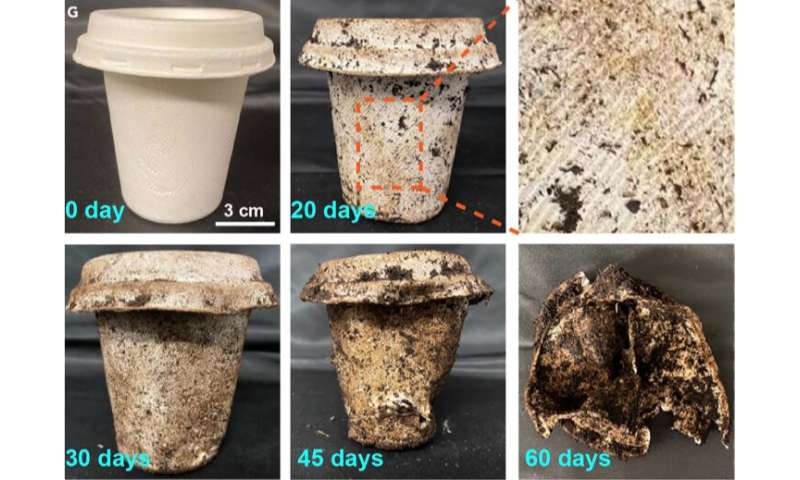

To find an alternative for plastic-based food containers, Zhu and her colleagues turned to bamboos and one of the largest food-industry waste products: bagasse, also known as sugarcane pulp. Winding together long and thin bamboo fibers with short and thick bagasse fibers to form a tight network, the team molded containers from the two materials that were mechanically stable and biodegradable. The new green tableware is not only strong enough to hold liquids as plastic does and cleaner than biodegradables made from recycled materials that might not be fully de-inked, but also starts decomposing after being in the soil for 30-45 days and completely loses its shape after 60 days.

Scientists have designed a set of "green" tableware made from sugarcane and bamboo that doesn't sacrifice on convenience or functionality and could serve as a potential alternative to plastic cups and other disposable plastic containers. Unlike traditional plastic or biodegradable polymers—which can take as long as 450 years or require high temperatures to degrade—this non-toxic, eco-friendly material only takes 60 days to break down and is clean enough to hold your morning coffee ordinner takeout. This plastic alternative is presented November 12 in the journal Matter.

"To be honest, the first time I came to the US in 2007, I was shocked by the available one-time use plastic containers in the supermarket," says corresponding author Hongli (Julie) Zhu of Northeastern University. "It makes our life easier, but meanwhile, it becomes waste that cannot decompose in the environment." She later saw many more plastic bowls, plates, and utensils thrown into the trash bin at seminars and parties and thought, "Can we use a more sustainable material?"

To find an alternative for plastic-based food containers, Zhu and her colleagues turned to bamboos and one of the largest food-industry waste products: bagasse, also known as sugarcane pulp. Winding together long and thin bamboo fibers with short and thick bagasse fibers to form a tight network, the team molded containers from the two materials that were mechanically stable and biodegradable. The new green tableware is not only strong enough to hold liquids as plastic does and cleaner than biodegradables made from recycled materials that might not be fully de-inked, but also starts decomposing after being in the soil for 30-45 days and completely loses its shape after 60 days.

A cup made from biodegradable materials. Credit: Liu et al

"Making food containers is challenging. It needs more than being biodegradable," said Zhu. "On one side, we need a material that is safe for food; on the other side, the container needs to have good wet mechanical strength and be very clean because the container will be used to take hot coffee, hot lunch."

The researchers added alkyl ketene dimer (AKD), a widely used eco-friendly chemical in the food industry, to increase oil and water resistance of the molded tableware, ensuring the sturdiness of the product when wet. With the addition of this ingredient, the new tableware outperformed commercial biodegradable food containers, such as other bagasse-based tableware and egg cartons, in mechanical strength, grease resistance, and non-toxicity.

"Making food containers is challenging. It needs more than being biodegradable," said Zhu. "On one side, we need a material that is safe for food; on the other side, the container needs to have good wet mechanical strength and be very clean because the container will be used to take hot coffee, hot lunch."

The researchers added alkyl ketene dimer (AKD), a widely used eco-friendly chemical in the food industry, to increase oil and water resistance of the molded tableware, ensuring the sturdiness of the product when wet. With the addition of this ingredient, the new tableware outperformed commercial biodegradable food containers, such as other bagasse-based tableware and egg cartons, in mechanical strength, grease resistance, and non-toxicity.

The decomposition of the biodegradable tableware over 60 days. Credit: Liu et al

The tableware the researchers developed also comes with another advantage: a significantly smaller carbon footprint. The new product's manufacturing process emits 97% less CO2 than commercially available plastic containers and 65% less CO2 than paper products and biodegradable plastic. The next step for the team is to make the manufacturing process more energy efficient and bring the cost down even more, to compete with plastic. Although the cost of cups made out of the new material ($2,333/ton) is two times lower than that of biodegradable plastic ($4,750/ton), traditional plastic cups are still slightly cheaper ($2,177/ton).

"It is difficult to forbid people to use one-time use containers because it's cheap and convenient," says Zhu. "But I believe one of the good solutions is to use more sustainable materials, to use biodegradable materials to make these one-time use containers."

Explore further Biodegradable plastics from palm oil waste

More information: Matter, Liu, Luan, and Li et al.: "Biodegradable, Hygienic, and Compostable Tableware from Hybrid Sugarcane and Bamboo Fibers as Plastic Alternative" www.cell.com/matter/fulltext/S2590-2385(20)30558-0 ,

The tableware the researchers developed also comes with another advantage: a significantly smaller carbon footprint. The new product's manufacturing process emits 97% less CO2 than commercially available plastic containers and 65% less CO2 than paper products and biodegradable plastic. The next step for the team is to make the manufacturing process more energy efficient and bring the cost down even more, to compete with plastic. Although the cost of cups made out of the new material ($2,333/ton) is two times lower than that of biodegradable plastic ($4,750/ton), traditional plastic cups are still slightly cheaper ($2,177/ton).

"It is difficult to forbid people to use one-time use containers because it's cheap and convenient," says Zhu. "But I believe one of the good solutions is to use more sustainable materials, to use biodegradable materials to make these one-time use containers."

Explore further Biodegradable plastics from palm oil waste

More information: Matter, Liu, Luan, and Li et al.: "Biodegradable, Hygienic, and Compostable Tableware from Hybrid Sugarcane and Bamboo Fibers as Plastic Alternative" www.cell.com/matter/fulltext/S2590-2385(20)30558-0 ,

Journal information: Matter

Provided by Cell Press

No comments:

Post a Comment