GOLD MINING IS NOT SUSTAINABLE

Spanish Mountain moves BC gold project forward with optimization and EA programs

Canadian Mining Journal Staff | September 9, 2021 |

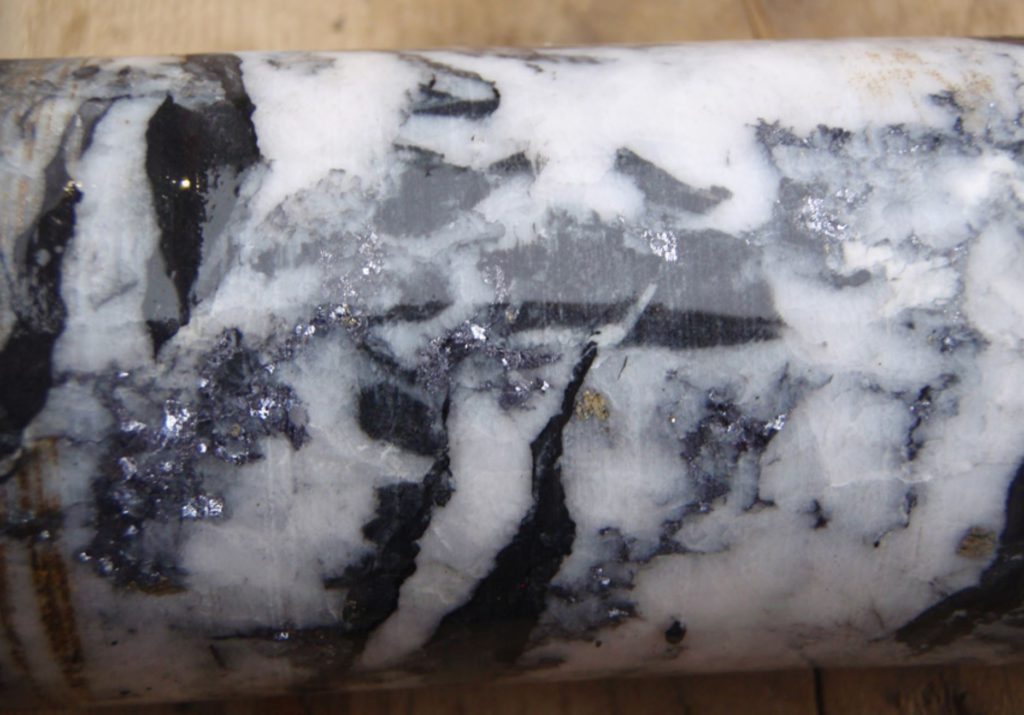

Visible gold and silver in core from Spanish Mountain in B.C. Credit: Spanish Mountain Gold

After releasing a prefeasibility study in May, Spanish Mountain Gold (ESXV: SPA) is moving its Spanish Mountain gold project forward. The company has launched several optimization initiatives and the environmental assessment for the project, located 70 km northeast of Williams Lake, British Columbia. Williams Lake, BC Map & Directions - MapQuest

To optimize gold recovery, Spanish Mountain has hired Ausenco Engineering Canada to go over the mill flowsheet, further reducing capital and operating costs. Under consideration is piloting a direct flotation reactor (DFR), simplifying the flowsheet, and boosting gold recovery through a finer primary grind, and the inclusion of a primary gravity circuit.

Linkan Engineering has been engaged to design a passive water treatment system that would inhibit neutral sulphide oxidation and associated metal leaching. Spanish Mountain says water management and treatment is a high priority for the project.

The company also has its engineers assessing the route of a power line to the project.

As the baseline environmental assessment studies continue, Spanish Mountain is consulting with the three First Nations that signed memoranda for engagement a decade ago. The initial project description (IPD) is nearing completion, and it will be circulated to the First Nations for comment and input before it goes to the provincial and federal regulators. A site-wide water balance program to study groundwater flows near the planned pit and tailings management area is also underway.

The company has an active program of exploration drilling to expand the resources ahead of the feasibility study. The geological model of the project suggests that mineralization is open at depth and along strike.

(This article first appeared in the Canadian Mining Journal)

The processing of gold scrap varies not only with the gold content but also with the amenability of the gold in the scrap to extraction. Thus, the bulk of the gold may be recovered by leaching techniques using cyanidation or aqueous chlorination, and the residue may then be treated by smelting to recover the balance.

https://www.911metallurgist.com/blog/gold-cil-process-explained 2013-01-02 · The carbon-in-pulp process is used to treat low grade gold and/or silver ores. The ore is first ground in a ball mill which operates in closed circuit with a cyclone …

New East zone at Red Chris mine shows promise

Canadian Mining Journal Staff | September 9, 2021 |

Expect the feasibility study for underground mining at Red Chris in the middle of next year. Credit: Imperial Metals

Imperial Metals (TSX: III) reports that drilling at the newly discovered East Ridge zone at the Red Chris copper-gold mine continues to return long and strong assays. The mine near Dease Lake, BC, is owned 70% by Australia’s Newcrest Mining (TSX: NCM; ASX: NSM) and 30% by Imperial.

Drill hole RD705 returned 254 metres of 1.1% copper and 1 g/t gold from a depth of 718 metres, including 80 metres of 1.4% copper and 1.6 g/t gold. Assays from this hole and the previously reported RC678 confirm the continuity of the mineralization over 300 metres vertically.

Drilling continues at the East Ridge zone, which is adjacent to the East zone, on a nominal 100 by 100 metre grid. Fourteen holes have been completed and six are in progress.

A stepout hole drilled 700 metres east of East Ridge returned 206 metres grading 0.5% copper and 0.2 g/t gold from 1,816 metres. This is one of the deepest intercepts on the property and extends the potential mineralization even further.

As operator, Newcrest is working on a prefeasibility study due this month of an underground block cave mine in addition to the open pit now being mined. Construction of an exploration decline into the East zone began earlier this year. Surface drilling has already confirmed the presence of several high grade pods in the zone, and development of a small underground producer would boost cash flow at the operation.

A full feasibility study for underground mining is due in mid-2022.

Last year the Red Chris mine produced 25,000 tonnes of copper and 39,000 oz. of gold.

(This article first appeared in the Canadian Mining Journal)

No comments:

Post a Comment