Simulation of bamboo's response to moisture used to prevent mold growth in building materials

As a rapidly growing renewable raw material, bamboo is an ideal substitute for wood. However, bamboo's susceptibility to mold in damp conditions poses a problem. Researchers at Fraunhofer have now analyzed bamboo's response to moisture under specific climatic conditions. By using simulation software, building owners can plan and implement measures to prevent the growth of mold.

In the era of climate change, bamboo ranks among the most promising construction materials. Bamboo is a rapidly growing renewable raw material, which absorbs CO2, and is resource-efficient and biodegradable. For this reason, the construction industry is increasingly choosing to use it as a substitute for wood, which is becoming scarce due to the increase in building activities across the globe.

However, Bambusoideae (scientific name for bamboo), part of the perennial grass family, poses a structural issue: Over the course of their centuries-long lifespan, trees build up resistance to harmful bacteria and mold. The lifespan of a bamboo stem, however, is only 20 years. As a result, it is less able to protect itself and is therefore vulnerable to mold infestation.

The Fraunhofer Institute for Building Physics IBP is now presenting a solution that helps to forecast bamboo's response to moisture, thereby enabling the humidity of the material to be managed efficiently. "The goal is to prevent the growth of mold without using chemical preservatives that can also harm humans," explains Prof. Dr. Hartwig Künzel, Head of Hygrothermics at Fraunhofer IBP.

Laboratory testing to determine material properties

The first step was to determine the hygrothermal material properties of bamboo under certain climatic conditions. Following studies in China, further tests were carried out at the outdoor testing facility at Fraunhofer IBP in Holzkirchen near Munich, Germany. Here, bamboo products were exposed to the weather while the climatic conditions were recorded in detail by a meteorological station. An expert team then examined the material in the laboratory. How much water and water vapor did the bamboo absorb? How much was released and how was moisture transported within the material? In the latter case, the material was examined using an MRI scanner, which revealed how the absorbed water was distributed and moved about within the material.

Simulation software for all climatic conditions

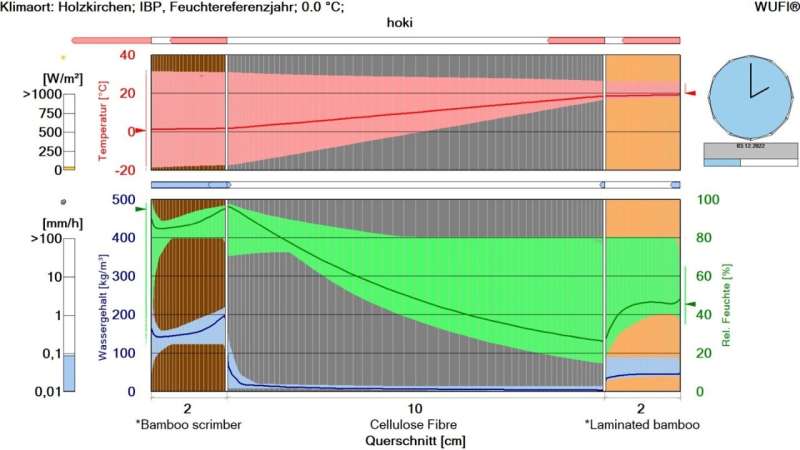

At the technological heart of the project was the hygrothermal simulation software WUFI. It uses a transient calculation method that has been validated in experiments across the world. This software enables the thermal and moisture conditions in components and buildings to be realistically simulated. Using the properties determined in the laboratory, the software simulates the behavior of bamboo when exposed to specific climatic conditions and presents the findings using an animated chart that shows progression over time. This can be used to derive the probability that mold will grow. Typically, mold starts to pose a risk to bamboo in ambient conditions of 80 percent relative atmospheric humidity. A construction company that uses bamboo for sustainable building construction can use the software analysis to implement measures that will provide effective framework conditions, such as protection against humidity.

"The WUFI software delivers reliable and detailed results on bamboo's response to moisture. This enables construction companies and architects to plan and build ecologically safe and sustainable buildings using bamboo as a building material," says Künzel. In addition, these findings can also be used to open up new areas of application for different materials made from bamboo.

The researchers developed the simulation software years ago. In light of the present increase in demand for wood substitutes, researchers at Fraunhofer have now also validated the software for bamboo. "There is a variety of versions of WUFI available, depending on the application and requirements. We also license these to international partners," says Künzel. Bamboo is best suited as a wood substitute. It is a fibrous, light material, which offers great long-term stability, and can be used to manufacture panels (such as wall paneling) in a similar way to wood. Bamboo can also be used for floorboards because it is very hard. Due to its flexibility, bamboo is ideal for construction in earthquake areas.

Fields of research: indoor climate, structural engineering and biohygrothermics

Reeds (Typha) are another environmentally friendly replacement for wood that Fraunhofer IBP has researched in the past. When used to construct walls, reeds act well as a stable, insulating and sustainable building material. Expertise regarding materials which can replace wood only makes up part of the specialist competence offered by Fraunhofer IBP. The institute, with sites in Stuttgart and Holzkirchen, has many years of expertise in building physics. This includes, for example, structural engineering, indoor climate and biohygrothermics, all of which are viewed from the standpoint of sustainability. By means of example, scientists are also researching air conditioning in aircraft and moisture management in packaging. Currently, there are plans for a project to assess the possibilities for climate-stable transport of sensitive goods.Bamboo lights a fire under Australian construction industry

Provided by Fraunhofer-Gesellschaft

No comments:

Post a Comment