Portable MicroFactory From Shipping Containers Runs on Solar Power, Reduces Plastic Waste

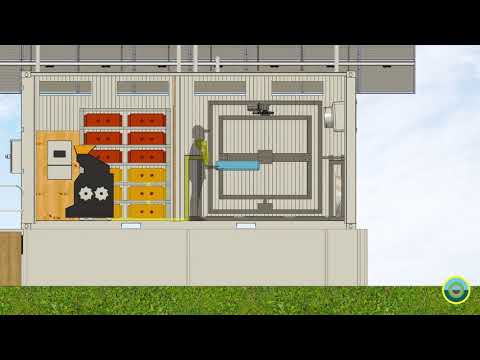

With a roof full of solar panels, the MicroFactory collects the solar energy and stores it in its batteries, which power the machinery used to process the plastic. CEM’s MicroFactory is equipped with a rotational molding machine and a plastic shredder, both powered by the aforementioned batteries. The factory comes with transparent walls that allow anyone to see what goes on inside.

Transforming the plastic into a new, eco-friendly product is a multi-step process. First, the plastic has to go through the shredder where it is turned into plastic flakes. Those flakes are then rinsed in a washer and placed into the rotational molding machine, which spins them and coats the interior of the mold with liquid plastic. The last step is for the mold to be left to cool and the plastic within to solidify.

Circular Economy Manufacturing buys the plastic locally, from a recycling plant in Brooklyn, but the great thing about its MicroFactory is that it is portable. The company plans to place such facilities all over the country, making CEM part of a circular economy instead of a linear one.

A linear economy is based on collecting the raw material, processing it, and turning it into a product that will eventually become waste, once it's no longer useful. On the other hand, a circular economy recycles the product and reuses it, minimizing waste and focusing on sustainability.

Honor’s new Intelligent Manufacturing Industrial Park is quite the modern marvel – Phandroid

It’s been quite an interesting couple of years for Honor, as the former Huawei sub-brand went through a period of turmoil following Huawei’s highly-publicized trade ban. Then, the company was spun off and separated from Huawei and has since released several new smartphones over the course of this year. The Honor 50 was the company’s first foray back into the smartphone market, which was then followed by the Honor Magic 3 flagship lineup.

This week, Honor announced its first “self-funded factory” which will help the company produce new phones at a much faster rate than previously. According to Honor, with the new Intelligent Manufacturing Industrial Park, it will be able to have a smartphone leave the production line every 28.5 seconds.

We are proud to announce the opening of our new manufacturing facility which will be integral to assuring our wider range of premium products are of the highest quality. As a premium technology product provider, being able to ensure our standards of reliability and quality will be paramount as we continue our journey to become a leading global technology brand – George Zhao, Honor CEO

While that’s an impressive number, what may be even more impressive is how precise the facility will be able to manufacture new smartphones. Honor claims it will be able to achieve assembly precision of up to 75 microns, which is essentially the size of a single human hair.

Additionally, the company confirmed it will be using more than 600 different quality standards, across the entire array of the process, including development, manufacturing, and finally, the user experience. This includes performing almost 200 “stringent tests on all incoming materials” to ensure that everything meets the quality that Honor wants to achieve with its smartphone lineup.

The park itself is located in Shenzhen, China, and handles everything from the testing of materials to the actual creation of the devices and packaging. All of this is rather impressive, especially when you consider that the facility was self-funded. Things are definitely looking up for Honor, and it’s come a long way from where it was just a couple of years ago.

No comments:

Post a Comment