Why You Should Care About Small Nuclear Reactors

The future might depend on it.

Nuclear power could become a crucial feature in a world free of fossil fuels.

This is why Rolls-Royce secured financial backing from a consortium of private investors and the U.K. government to build small modular nuclear reactors capable of generating cleaner energy in the region, according to a press release from the company.

As of writing, roughly 16% of the United Kingdom's electricity comes from nuclear power, but this could start dropping soon. "A lot of existing reactors [in the U.K.] are nearing the end of their lifetime," said Professor Michael Fitzpatrick, Pro-Vice-Chancellor for Engineering, Environment, and Computing at the U.K.'s Coventry University, who's also an expert in nuclear energy, to Interesting Engineering. "We have to be replacing these just to stand still in terms of keeping nuclear at its portion of the electricity grid."

And, as more nations face the hard facts of solar and wind's intermittency issues, new investments in nuclear power like Rolls-Royce's small modular reactors could help the world balance the energy gaps left by renewables, and achieve net-zero carbon goals, on time.

Rolls-Royce's new SMR nuclear reactors will help the UK achieve its net-zero carbon goals

Following the roughly $260 million (£195 million) cash injection from private firms, in addition to the roughly $280 million (£210 million) from the U.K. government, the Rolls-Royce Small Modular Reactor (SMR) company was formally announced. And it could generate up to 40,000 jobs by 2050, according to a BBC report. Small Modular Reactors are essentially just like conventional ones; they use fuels like uranium to heat water, and then transfer that thermal energy into electrical energy, releasing only harmless steam (water vapor) into the atmosphere. But SMRs are tailored to suit any economic scenario. "SMRs allow you to do a mix where the endpoint is the same," said Fitzpatrick to IE. "The same ability to meet energy demands, but at different levels of commitment", both financially and in terms of scale. "It's a lower up-front cost, with a shorter build time."

In the release, Rolls-Royce SMR said one of its power stations would take up the space equivalent to roughly one-tenth of the space of conventional nuclear plants, and generate enough power to supply electricity to one million households. One SMR plant could generate 470 MW of power, which could be thrown into the mix of conventionally renewable power, like the more than 150 onshore wind turbines. Each SMR should cost roughly $2.7 billion (£2 billion) to construct, far less than the roughly $27 billion (£20 billion) needed to build conventional (full-scale) reactors. This lower cost makes SMRs a more viable alternative to fossil fuels, on similar financial standing as major wind and solar installations.

Solar and wind lack the means to store adequate power

Critics of the new investment in nuclear and the Rolls-Royce SMR business argue that the focus of the energy industry should be on renewable power, instead of new nuclear. But according to Fitzpatrick, this is a false dilemma. "The question of renewables and nuclear shouldn't be seen as an either/or," he said. "In the same way, we should be investing in many energy storage options, including hydrogen." Still, this raises the question: is nuclear really clean energy? It still produces toxic waste, and that's bad for the environment. But the kind of waste we see from nuclear power isn't driving a global climate catastrophe. "The waste is unpleasant stuff and it's potentially harmful," explained Fitzpatrick to IE. "But stacked against CO2, you're not really comparing like with like." The surge in global temperatures is directly linked to CO2 levels, which are drastically reshaping our atmosphere to the limits of human habitability, almost single-handedly thanks to fossil fuel industries.

"In other words, nuclear waste does not raise the same problem that fossil fuel pollution creates," said Fitzpatrick. And they also address a major issue with solar and wind power, which can't store enough power when there's no wind or sunlight. "Right now renewables suffer from intermittency. When wind speed drops, you need a gas turbine to cover" for wind turbines. "In the U.K. we've restarted coal fire plants to cover the gap. You need a way of storage for what's being generated by renewables (and we're no way near at the scale to do that)." It's difficult to overstate how serious this flaw in solar and wind can be on a practical level. "Would society accept on a calm still winter night that we should be prepared to do without heating in hospitals, or industry in general?" asked Fitzpatrick, rhetorically. The waste from nuclear power is also a flaw, but its effects don't tread water next to the ravages of excess CO2.

France, too, is investing in nuclear power

"Some people say you just can't store waste underground" like it's an absolute ethical principle, added Fitzpatrick to IE. "But carbon storage is exactly that; storing waste underground. And CO2 is the same forever. It has no half-life." The advantages of using nuclear often go unspoken because it simply hasn't shared the same spotlight that renewables have in the last decade or two. But "with nuclear, you're taking a tech that we know works, and investing it to deploy rapidly at scale." And the U.K. is not alone in realizing this.

On Tuesday, President Macron announced that France will build new nuclear reactors, specifically to meet global warming targets and keep energy prices under control, according to a Reuters report. This fits Fitzpatrick's rationale for emphasizing nuclear in national grids throughout the world. "If you're serious about making decarbonization commitments, you have to be investing in nuclear. We need a low-carbon baseload, and I think more governments are going to come to that conclusion, and I think that's going to drive a global nuclear renaissance." Right now, solar and wind power have already reached a serious limit, and it's one that was there all along: when the sun goes down, and the wind calms, there's not enough stored energy to keep an energy grid going. "Right at the moment the way we cover the intermittency gap is by using fossil fuels," said Fitzpatrick. But nuclear can fill these gaps, maintain energy levels, and it's just getting started. "Nuclear should not just be about technologies we have today, but also about the technologies we want to build in 30, 40, or 50 years."

Thorium-Fueled Reactors Offer Huge Potential Benefits for the Nuclear Power Industry

Nuclear power opponents often point to radioactive waste as one of their main concerns. However, most people don’t realize that problems associated with long-lived waste can actually be solved in an economic way with technology that’s already well-proven. Long-lived actinides can be “burned” in a thorium molten salt reactor (MSR), or a breeder reactor. They do not burn fast, but in this way, it is possible to convert the most problematic part of the waste from something that needs to be stored safely for tens of thousands of years to fission products that only need to be stored safely for about 300 years.

“Breeding is where you actually convert what’s called a fertile fuel—and thorium is one of these fertile fuels—you convert that into something which you can fission, and then you have to make sure that that process actually doesn’t stop—that it continues to create more and more new fuel,” Thomas Jam Pedersen, co-founder of Copenhagen Atomics, said as a guest on The POWER Podcast. “That’s what Copenhagen Atomics is trying to prove to the world—that it’s not merely something that you can show from physics that it’s possible, but you could actually also build it and make it work.”

The concept is not new. MSRs—a class of reactors that use liquid salt, usually fluoride- or chloride-based, as either a coolant with a solid fuel or as a combined coolant and fuel with the fuel dissolved in a carrier salt—underwent significant testing in the 1950s and 1960s at the Oak Ridge National Laboratory (ORNL) in Tennessee. Subsequent design studies in the 1970s focusing on thermal-spectrum thorium-fueled systems established reference concepts for two major design variants, one of which was a molten salt breeder reactor with multiple configurations that could breed additional fissile material or maintain self-sustaining operation.

One reason the testing stopped was because thorium is not well-suited for making nuclear weapons, so the military was not interested in investing in the technology. “It was, from the very get-go, far behind the investments in the uranium fuel cycle, and therefore, most people were educated in the uranium fuel cycle,” Pedersen said.

In the late 2000s, that changed, because documents from the ORNL testing were released to the public. “People started to discover, ‘Oh, there’s actually something here that is quite exciting.’ Because thorium is the only element where you can make breeder cycle, or breeder reactor, in thermal spectrum, and thermal spectrum is sort of, you can say, the easy reactors to build,” Pedersen explained

Molten salt is an important part of the process because it allows fission products to be removed from the reactor during operation. In the past, corrosion was a serious problem when using molten salt, but with today’s advanced materials, it’s less of a concern and less expensive to control. “Back in the day, there was not that much material science, and it was difficult to make the salt clean enough that you could minimize the corrosion,” said Pedersen. “I think this is where we’ve gotten a step ahead now with modern technology.”

Copenhagen Atomics’ goal is to have a 100-MWth (roughly 45-MWe) reactor unit available commercially by 2028. Units are expected to be built in a factory, using an assembly-line process, and will be roughly the size of a standard shipping container, which will allow them to be delivered easily to plant construction sites around the world. Customers would be able to install multiple units at a site to effectively create almost any size plant.

“One of the problems with classical reactors is that they’re usually really, really big and built onsite, and are quite expensive, and take many years to build,” Pedersen said. “We started this company because we want to change that. We want to be able to deploy these reactors much faster. Our ambition is to build more than one every day.”

The company expects to have a non-fission prototype unit ready for operation next year. “We will be able to test it—it’s a one-to-one scale model of the reactor—we will not be able to run fission inside, but we can start it up and we can pump the salt around and we can test all the systems—see that it’s working,” Pedersen said. Copenhagen Atomics is targeting 2025 to have a fully functioning demonstration reactor in operation.

One additional advantage of the MSR is that molten salt is a great energy storage medium, so Pedersen said he envisions storage tanks at plant sites that will allow units to operate as baseload units, even in a renewable-filled market. “We plan to put all the output energy into that tank when, say, the wind is blowing. And then when the wind is not blowing, then you can both take the power from the reactor and you can take some of the additional power from those storage tanks.”

The cost? “I think it’ll be a much cheaper energy form than classical nuclear reactors, and I think we can even compete with some of the cheapest forms of wind power or solar power,” said Pedersen. Furthermore, the thorium-fueled units will be dispatchable. “We can supply energy 24/7, and therefore, the value of our energy source is higher in the grid than it would be if you buy the same electricity from solar.”

To hear the full interview with Pedersen, which includes information about partners, the research and development process, how exciting new reactor technology is inspiring younger people to join the industry, and more, listen to The POWER Podcast. Click on the SoundCloud player below to listen in your browser now or use the following links to reach the show page on your favorite podcast platform:

For more power podcasts, visit The POWER Podcast archives.

—Aaron Larson is POWER’s executive editor (@AaronL_Power, @POWERmagazine).

Industry’s First Complete Accident-Tolerant Nuclear Assembly in Operation at Calvert Cliffs

The first complete accident-tolerant fuel (ATF) assembly is now operational at Exelon’s Calvert Cliffs Nuclear Power Plant Unit 2 in Maryland, bringing an industry-led quest to accelerate commercialization of the new nuclear technology closer to fruition.

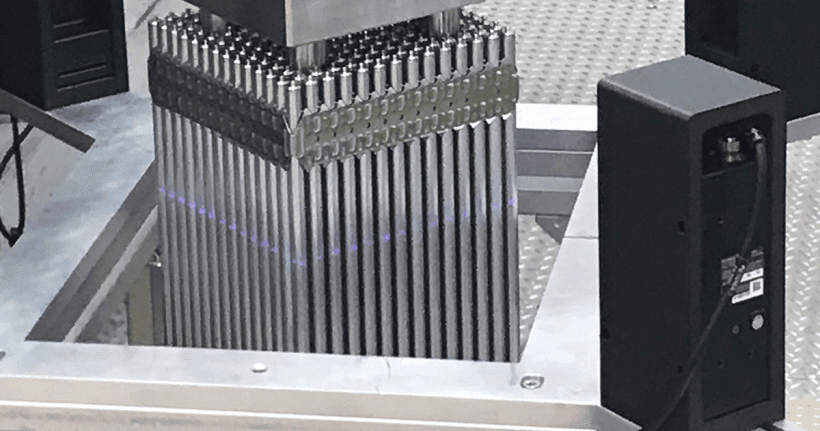

Inserted during the plant’s recent spring refueling outage, the lead fuel assembly (LFA) features a Framatome PROtect fuel design that was developed under the U.S. Department of Energy’s (DOE’s) Accident Fuel program. The pioneering LFA includes 176 chromium-coated rods and chromia-enhanced pellets that are “more tolerant to changes in reactor core temperatures increasing coping time, while reducing corrosion and the production of hydrogen under high-temperature conditions,” the French nuclear giant said.

According to the DOE, the advanced fuel will now operate in the reactor for the next four to six years and will be routinely inspected to monitor its performance. The Nuclear Regulatory Commission (NRC) in January amended Exelon’s Calvert Cliff operating license, allowing Exelon to install up to two Framatome PROtect lead test assemblies at the 1.9-GW nuclear plant’s two 860-MW pressurized water reactors for up to three cycles.

Framatome noted that the LFA was fabricated at its manufacturing facility in Richland, Washington, as part of a 2019 contract with Exelon Generation. However, the new fuel prototype builds on previous testing in the U.S., including an 18-month fuel cycle test, and Switzerland through Framatome’s PROtect program.“Loading the first complete accident tolerant fuel assembly is a huge milestone for Framatome and the nuclear energy industry,” said Lionel Gaiffe, senior executive vice president of Framatome’s Fuel Business Unit.

Frank Goldner, a nuclear engineer within DOE’s Office of Nuclear Energy, noted the milestone is also a triumph for Exelon and “the entire industry at large.” ATF, an industry concept used to describe new technologies in the form of new cladding and/or fuel pellet designs, has morphed into a key priority for the U.S. nuclear power industry because it promises to improve the existing nuclear fleet’s cost competitiveness in power markets that are increasingly inundated with cheap renewables and natural gas power. “Accident tolerant fuels are expected to enhance the performance of today’s reactors and will help fuel our future path to reaching net-zero emissions by 2050,” Goldner added

ATFs Set for ‘Widespread’ Adoption by 2030

While ATF technologies have been under development since the early 2000s, they received a marked boost in the wake of the March 2011 Fukushima accident as the DOE aggressively implemented plans under its Congressionally mandated Enhanced Accident Tolerant Fuel (EATF) program to develop ATFs for existing light water reactors (LWRs). The DOE has said these technologies are being developed under an “accelerated timeframe,” owing mainly to the status of the nation’s current fleet of reactors. Earlier this year, the agency told POWER a private-public collaboration to commercialize ATFs is “still on track for initial commercial introduction of accident tolerant fuel by 2025.”

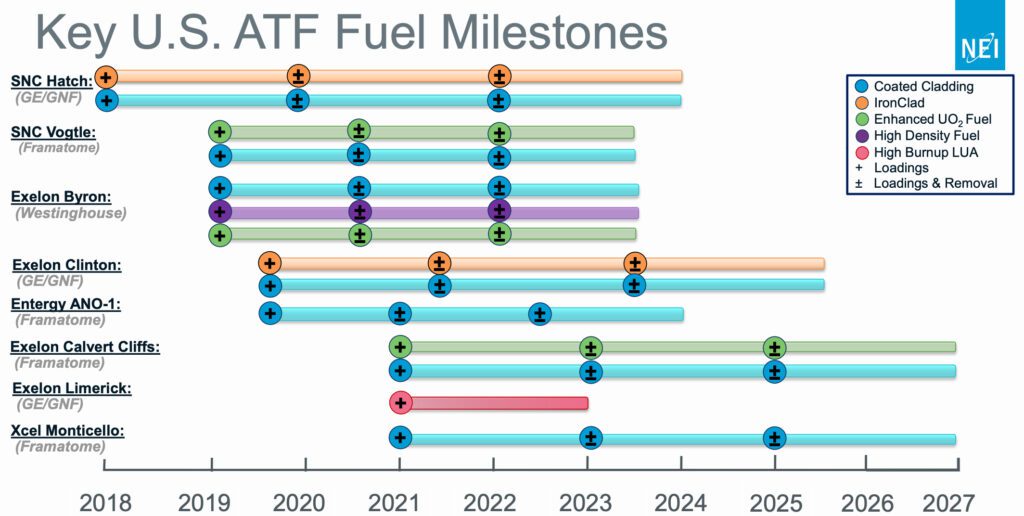

Backed by the DOE and monitored by the NRC, since spring 2018, GE’s Global Nuclear Fuel (GNF), Westinghouse, and Framatome have so far loaded lead test assemblies (LTAs) containing “near-term” ATF technologies at 10 U.S. nuclear plants. Tests of loaded fuel are ongoing or planned at another four nuclear plants.

The DOE said on Tuesday all three vendors are “currently on track to have their accident tolerant fuels ready for batch loading by the mid-2020s and with commercial widespread adoption by 2030.”

A Brief Recap of ATF Achievements

So far, GNF has tested several different iron-chromium-aluminum (FeCrAl) alloys for cladding. In December 2020, Oak Ridge National Laboratory said it received the first GNF-developed nuclear fuel test rods, which spent 24 months at Southern Co.’s Edwin Hatch nuclear plant. The test samples feature IronClad, an FeCrAl fuel cladding, and ARMOR, a hard, oxidation-resistant coating layered on top of zirconium cladding with uranium oxide (UO2) fuel (which GNF originally created outside of the DOE’s ATF program).

Framatome, meanwhile, is working to commercialize a near-term ATF design that involves chromium-coated zirconium alloy cladding with chromia (Cr2O3)–doped UO2 fuel. Four GAIA LTAs containing Framatome’s advanced chromium coating (which is added to its proprietary M5 zirconium alloy cladding) and the chromia-doped pellets were removed after an 18-month cycle at Southern Co.’s Vogtle 2 plant in August 2020. Two other 18-month cycles of operation for the LTAs are planned. Framatome’s concepts are also being tested at Entergy’s Arkansas Nuclear One (ANO) Unit 1. In the fall of 2019, ANO Unit 1 inserted 32 Framatome Cr-coated lead test rods. The full assembly inserted at Calvert Cliffs this spring includes Cr-coated M5 cladding and Cr2O3-doped UO2 fuel.

Westinghouse is also testing several “near-term” technologies developed under its EnCore Fuel brand. These include “improved chromium-coated cladding that inhibits the zirconium-steam reaction and increases maximum temperature by an additional 300C,” as well as Westinghouse’s proprietary ADOPT fuel pellets, which are chromia and alumina (Cr2O3 + Al2O3)—doped UO2. The additives in the doped fuel “facilitate greater densification and diffusion during sintering, resulting in a higher density and an enlarged grain size as compared to undoped UO2,” the company said in topical report that the NRC accepted for review in September 2020.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

No comments:

Post a Comment