An electrically charged thin film patch used to promote wound healing

A team of researchers working at the University of Electronic Science and Technology of China has developed an electrically charged thin film patch for promoting faster wound healing. In their paper published in the journal Science Advances, the group describes their patch, how it works, and how well it performed when tested on rats.

Humans have been looking for ways to promote faster healing of wounds for thousands of years in order to reduce both the length of time a patient experiences pain and the chances of infection. In this new effort, the researchers created an electrically charged thin film patch that helps wounds heal faster.

Prior research has shown that applying electricity to wounds induces faster healing. Unfortunately, this approach has been limited by bulky and complicated machinery. In this new effort, the researchers created a small, flexible patch that takes advantage of electricity's healing powers without the need for such equipment.

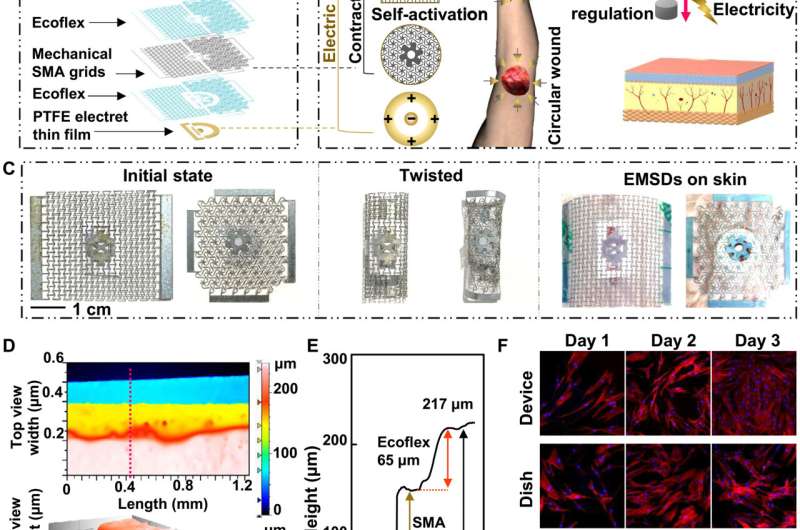

The patch is four-layered: the top and bottom layers are made of a type of electrically charged plastic and they get their charge through contact with the skin. One of the middle layers is made of a silicone rubber gel that helps the patch conform to the contours of the skin. The other middle layer is made of a shape-memory alloy material; its purpose is to pull the sides of the wound closer. The resulting thin-film patch is just 0.2 millimeters thick.

The researchers applied the patch to two kinds of wounds on test rats—straight and circular. They compared healing rates against other types of dressings and against undressed wounds. They found that circular wounds treated with the patch were 96.8% healed after eight days, compared to 76.4 to 79.9% for other dressings. Those that went untreated were only 45.9% healed. They found similar results in straight-line wound healing, though all of them healed faster than the circular wounds—such wounds require far less new skin development to heal.

The researchers suggest their patch is a viable wound treatment option and plan to continue upgrading its features, such as allowing for differently shaped wounds.

F

No comments:

Post a Comment