Alexa St. John

Thu, December 15, 2022

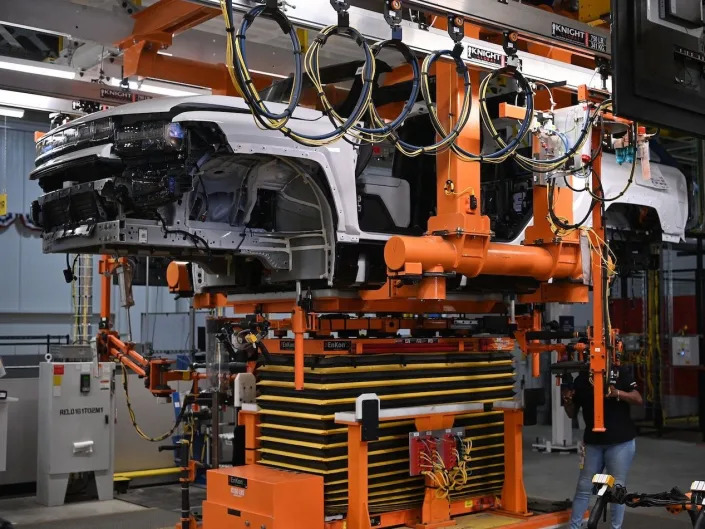

Automakers might need to copy Tesla's playbook for battery sourcing. Here, a battery is installed in the Hummer EV.

Mandel Ngan/Getty Images

Auto companies need EV battery supply more than ever, but the costs are adding up.

Prices and a push to use local materials have carmakers investing in in-house battery supply.

This move copies what Tesla has long been doing for years.

With electric car battery costs on the rise, auto companies are doing everything they can to make their EV offerings more affordable for the masses in the coming years.

Making that happen may require forgetting much of what they've learned about supply chains over a century, and replacing it with a few pages from Tesla's playbook.

Automakers have been trying to evade today's EV woes by exploring different kinds of batteries to slash their dependence on the in-demand materials found in traditional lithium-ion setups. They've also been ramping up battery recycling efforts and working to return lithium, nickel, cobalt and more into the supply chain.

These solutions come with challenges in terms of timing and expense, at least in the near term. That means car companies are seeking an alternative and racing to secure their battery supply in the US.

That means making investments in battery material sourcing, battery production, and more, to reduce the global supply disruptions the industry saw from the pandemic.

"Almost all the major companies are investing in that for that very reason: to vertically integrate more and get more control of their supply chain," said Peter Maithel, auto industry principal analyst at Infor.

Auto companies need EV battery supply more than ever, but the costs are adding up.

Prices and a push to use local materials have carmakers investing in in-house battery supply.

This move copies what Tesla has long been doing for years.

With electric car battery costs on the rise, auto companies are doing everything they can to make their EV offerings more affordable for the masses in the coming years.

Making that happen may require forgetting much of what they've learned about supply chains over a century, and replacing it with a few pages from Tesla's playbook.

Automakers have been trying to evade today's EV woes by exploring different kinds of batteries to slash their dependence on the in-demand materials found in traditional lithium-ion setups. They've also been ramping up battery recycling efforts and working to return lithium, nickel, cobalt and more into the supply chain.

These solutions come with challenges in terms of timing and expense, at least in the near term. That means car companies are seeking an alternative and racing to secure their battery supply in the US.

That means making investments in battery material sourcing, battery production, and more, to reduce the global supply disruptions the industry saw from the pandemic.

"Almost all the major companies are investing in that for that very reason: to vertically integrate more and get more control of their supply chain," said Peter Maithel, auto industry principal analyst at Infor.

Volkswagen is building a battery cell factory at its Salzgitter site for its planned large-scale production of the Group's own battery cells.

Julian Stratenschulte/picture alliance via Getty Images

What's the rush?

In the past, car companies have expanded their supply chains across the globe, relying on slews of suppliers for each component of a car. Some of their key parts might come from the US, while others might come from Europe or Asia.

Historically, the breadth of those supply chains has reduced potential bottlenecks. But the pandemic — and other disruptions, like natural disasters — shed a light on just how vulnerable that can also make auto companies. If an auto parts plant across the world sees even a minor disruption, that could bring down a manufacturing line for days or weeks at a time.

The dawn of EVs, and the nuances in sourcing for these cars, brings those concerns and more to the forefront of automaker to-do lists. The US in particular has relied on foreign sources for battery supplies, components, and processing. China, meanwhile, has had a headstart in terms of sitting on the raw materials necessary to power EVs and controlling production of much of the world's battery cells, packs, and more.

But whether it's an unforeseen disruption like COVID-19 or a geopolitical issue, that leaves companies pretty vulnerable — and has encouraged them to bring manufacturing closer to home. There's been a general push to get away from that world-wide supply chain model anyway, driven by this summer's climate law.

"We've just seen an unprecedented amount of announcements, joint development agreements, early supply contracts from the automakers with battery materials providers, with battery manufacturers," said Matt Sculnick, executive director of Nomura GreenTech's advanced transportation team, "in a collaborative way that I don't think we've really seen."

Rivian manufactures its EVs in Illinois. Rivian

Good news for EV adopters — eventually

It's called vertical integration — and it's something Tesla has long been known for.

"Tesla is always the groundbreaker here, going directly to the source, going directly to the mines and negotiating supply contracts with the mines," said Alvarez & Marsal managing director Tony Lynch.

It's given Tesla an advantage in terms of having visibility into production, while GM and Ford and others scramble to get in on US mining deals and manufacturing.

It's complicated and time-consuming, but may ultimately be the best way car companies can get closer to lowering the cost of new EVs. Those sat at about $65,041 in November, according to Kelley Blue Book — when a new gas-powered car averaged $48,681 that same period.

More supply in general, but especially in the US, combined with more EV volumes, will drive that down.

Legacy Automakers Keep Taking Pages From Tesla's Playbook Despite CEO Controversy

Upwallstreet

Thu, December 15, 2022

According to BloombergNEF, battery prices rose for the first time in a decade. However, BloombergNEF experts don’t expect the rising costs for battery ingredients like lithium, cobalt, and nickel to impact vehicle prices anytime soon. Moreover, they expect it to be a temporary bump as BNEF predicts prices will drop in 2024, as more lithium production comes online.

Still, it's not good news for both legacy automakers as well as EV start-ups that desperately need profits from EVs to come as soon as possible to offset intense capital costs.

With rising costs and global pressures, automakers are trying to localize production and secure an in-house battery supply. Therefore, automakers seem to be taking another page from Tesla’s playbook despite the EV pioneer not doing so well in face of its share price dropping 61 percent since the beginning of the year, underperforming Ford and GM.

Forgetting everything they know

Automakers have been trying to evade the electric trend by exploring different kinds of batteries, ramping up battery recycling efforts and working to return lithium, nickel and cobalt into the supply chain. But, the existing knowledge does not help much in this equation as a new electric world comes with a new set of rules that is forcing automakers to vertically integrate and get more control of their supply chain.

Global supply chain is now a weakness

Historically, a global supply chain with a variety of players has reduced the risk pf potential bottlenecks. But natural disasters and most recently, the COVID-19 pandemic, revealed that such constitution makes automakers extremely vulnerable as even minor disruptions ended up halting the manufacturing line for days or even weeks.

Bringing manufacturing closer to home

This year, we’ve witnessed an unprecedented amount of joint development agreements, early supply contracts and similar announcements. These kind of agreements are always complex and significant time is needed for them to bear fruits but they seem to be the best way to make EVs more affordable.

Even the legendary automakers cannot pull it off alone. GM made a multimillion investment into Australia’s Controlled Thermal Resources (CTR) to extract lithium from California. Back in July, Ford Motor revealed it will buy lithium from Ioneer Ltd's (INR.AX) Rhyolite Ridge mining project in Nevada.

Worksport

Worksport Ltd. (NASDAQ: WKSP) is a company commited to changing the rules of the game both in the energy and automotive industry. With solar powered tonneau covers among its many intellectual properties, its subsidiary Terravis Energy Inc is developing a Non-Parasitic Electric Vehicle (NPEVTM) charging platform. Moreover, to minimize geopolitical risks that are very much in the air these days, the company added a manufacturing facility in the U.S. The 222,000-square-foot facility is expected to be up and running at full capacity soon.

Mercedes Benz

Automakers are also investing heavily into battery development in an effort to reduce their dependence on lithium and other highly prices and demanded battery ingredients.

On Wednesday, Mercedes-Benz unveiled its over $1.06 billion plan to adapt its entire global production network for electric powertrain systems from 2024.

With plants in Germany, Beijing and Romania, the premium automaker has set up its lines to produce both traditional combustion engines and EVs, but assembling batteries and motors on the same line is a more challenging task. The automaker stated that many of its component-making plants will continue making parts for internal combustion cars, as long as there is demand. Therefore, the automaker is striving for all-electric sales by the end of the decade but where the market conditions allow for it.

Tesla’s flamboyant CEO is feared to be distracted

Although no one can argue that Tesla is the company who started all this EV frenzy, concerns are in the air as its CEO, Elon Musk, has sold another round of stock valued at $3.6 billion. What is worrying is that Musk stated in April that there would be “no further TSLA sales” to support his acquisition of Twitter acquisition. Since the takeover, thebillionaire has sold $23 billion of Tesla stock and is found by many to be distracted and even absent. Although Musk tried to address concerns on Tuesday, stating that he will make sure that Tesla shareholders benefit from Twitter long-term, this proclamation was overshadowed by the controversy surrounding the management of the never-boring social network. Tesla did an extraordinary job but as we all know too well, future is promised to no one, and therefore, taking pages from its book in this ever changing climate is not necessarily a good idea.

See more from Benzinga

Semiconductors, The Fourth Industrial Revolution and the End of Globalization

Getting EVs To Go Further Does Not Have To Be Entirely About Changing Battery Technology

It's called vertical integration — and it's something Tesla has long been known for.

"Tesla is always the groundbreaker here, going directly to the source, going directly to the mines and negotiating supply contracts with the mines," said Alvarez & Marsal managing director Tony Lynch.

It's given Tesla an advantage in terms of having visibility into production, while GM and Ford and others scramble to get in on US mining deals and manufacturing.

It's complicated and time-consuming, but may ultimately be the best way car companies can get closer to lowering the cost of new EVs. Those sat at about $65,041 in November, according to Kelley Blue Book — when a new gas-powered car averaged $48,681 that same period.

More supply in general, but especially in the US, combined with more EV volumes, will drive that down.

Legacy Automakers Keep Taking Pages From Tesla's Playbook Despite CEO Controversy

Upwallstreet

Thu, December 15, 2022

According to BloombergNEF, battery prices rose for the first time in a decade. However, BloombergNEF experts don’t expect the rising costs for battery ingredients like lithium, cobalt, and nickel to impact vehicle prices anytime soon. Moreover, they expect it to be a temporary bump as BNEF predicts prices will drop in 2024, as more lithium production comes online.

Still, it's not good news for both legacy automakers as well as EV start-ups that desperately need profits from EVs to come as soon as possible to offset intense capital costs.

With rising costs and global pressures, automakers are trying to localize production and secure an in-house battery supply. Therefore, automakers seem to be taking another page from Tesla’s playbook despite the EV pioneer not doing so well in face of its share price dropping 61 percent since the beginning of the year, underperforming Ford and GM.

Forgetting everything they know

Automakers have been trying to evade the electric trend by exploring different kinds of batteries, ramping up battery recycling efforts and working to return lithium, nickel and cobalt into the supply chain. But, the existing knowledge does not help much in this equation as a new electric world comes with a new set of rules that is forcing automakers to vertically integrate and get more control of their supply chain.

Global supply chain is now a weakness

Historically, a global supply chain with a variety of players has reduced the risk pf potential bottlenecks. But natural disasters and most recently, the COVID-19 pandemic, revealed that such constitution makes automakers extremely vulnerable as even minor disruptions ended up halting the manufacturing line for days or even weeks.

Bringing manufacturing closer to home

This year, we’ve witnessed an unprecedented amount of joint development agreements, early supply contracts and similar announcements. These kind of agreements are always complex and significant time is needed for them to bear fruits but they seem to be the best way to make EVs more affordable.

Even the legendary automakers cannot pull it off alone. GM made a multimillion investment into Australia’s Controlled Thermal Resources (CTR) to extract lithium from California. Back in July, Ford Motor revealed it will buy lithium from Ioneer Ltd's (INR.AX) Rhyolite Ridge mining project in Nevada.

Worksport

Worksport Ltd. (NASDAQ: WKSP) is a company commited to changing the rules of the game both in the energy and automotive industry. With solar powered tonneau covers among its many intellectual properties, its subsidiary Terravis Energy Inc is developing a Non-Parasitic Electric Vehicle (NPEVTM) charging platform. Moreover, to minimize geopolitical risks that are very much in the air these days, the company added a manufacturing facility in the U.S. The 222,000-square-foot facility is expected to be up and running at full capacity soon.

Mercedes Benz

Automakers are also investing heavily into battery development in an effort to reduce their dependence on lithium and other highly prices and demanded battery ingredients.

On Wednesday, Mercedes-Benz unveiled its over $1.06 billion plan to adapt its entire global production network for electric powertrain systems from 2024.

With plants in Germany, Beijing and Romania, the premium automaker has set up its lines to produce both traditional combustion engines and EVs, but assembling batteries and motors on the same line is a more challenging task. The automaker stated that many of its component-making plants will continue making parts for internal combustion cars, as long as there is demand. Therefore, the automaker is striving for all-electric sales by the end of the decade but where the market conditions allow for it.

Tesla’s flamboyant CEO is feared to be distracted

Although no one can argue that Tesla is the company who started all this EV frenzy, concerns are in the air as its CEO, Elon Musk, has sold another round of stock valued at $3.6 billion. What is worrying is that Musk stated in April that there would be “no further TSLA sales” to support his acquisition of Twitter acquisition. Since the takeover, thebillionaire has sold $23 billion of Tesla stock and is found by many to be distracted and even absent. Although Musk tried to address concerns on Tuesday, stating that he will make sure that Tesla shareholders benefit from Twitter long-term, this proclamation was overshadowed by the controversy surrounding the management of the never-boring social network. Tesla did an extraordinary job but as we all know too well, future is promised to no one, and therefore, taking pages from its book in this ever changing climate is not necessarily a good idea.

See more from Benzinga

Semiconductors, The Fourth Industrial Revolution and the End of Globalization

Getting EVs To Go Further Does Not Have To Be Entirely About Changing Battery Technology

Elon Musk's former right-hand man is taking the next big step in his plan to make EVs cheaper by recycling old batteries

Alexa St. John

Wed, December 14, 2022

Redwood Materials employees taking a battery module apart.

Redwood recycles and refines the many precious materials — like lithium, nickel, and cobalt — found in used lithium-ion batteries from electric cars and consumer electronics

Alexa St. John

Wed, December 14, 2022

Redwood Materials employees taking a battery module apart.

Redwood Materials

The EV battery recycling giant just announced a new plant in South Carolina.

The plant will help carmakers get the materials they need to make EV batteries.

The news is also critical as car companies race to respond to this summer's climate law.

Electric vehicle battery recycling giant Redwood Materials is spending $3.5 billion on a new factory, and its location near the heart of the American "battery belt" is crucial to auto companies for a few reasons.

Run by Elon Musk's former right-hand man at Tesla, JB Straubel, Redwood recycles and refines the many precious materials — like lithium, nickel, and cobalt — found in used lithium-ion batteries from electric cars and consumer electronics, then sends them back into the supply chain.

The company's new plant, its second, will sit near Charleston, South Carolina. Redwood says it will break ground in the first quarter of 2023, have it up-and-running by the end of the year, and soon have it supply 1 million EVs annually.

While Redwood's flagship plant is near its Carson City, Nevada headquarters, this one's in the "battery belt": A stretch across the country, particularly in the Southeast, where car companies, battery makers, and more are setting up new EV development shops.

The EV battery recycling giant just announced a new plant in South Carolina.

The plant will help carmakers get the materials they need to make EV batteries.

The news is also critical as car companies race to respond to this summer's climate law.

Electric vehicle battery recycling giant Redwood Materials is spending $3.5 billion on a new factory, and its location near the heart of the American "battery belt" is crucial to auto companies for a few reasons.

Run by Elon Musk's former right-hand man at Tesla, JB Straubel, Redwood recycles and refines the many precious materials — like lithium, nickel, and cobalt — found in used lithium-ion batteries from electric cars and consumer electronics, then sends them back into the supply chain.

The company's new plant, its second, will sit near Charleston, South Carolina. Redwood says it will break ground in the first quarter of 2023, have it up-and-running by the end of the year, and soon have it supply 1 million EVs annually.

While Redwood's flagship plant is near its Carson City, Nevada headquarters, this one's in the "battery belt": A stretch across the country, particularly in the Southeast, where car companies, battery makers, and more are setting up new EV development shops.

Redwood recycles and refines the many precious materials — like lithium, nickel, and cobalt — found in used lithium-ion batteries from electric cars and consumer electronics

Redwood Materials

Ford established its BlueOval City campus in Tennessee and two battery plants in Kentucky. GM, through its Ultium Cells joint venture with LG Energy Solution, is also investing in battery-making in Tennessee. Panasonic is building a new battery factory in Kansas. Hyundai is investing in EVs and battery production in Georgia.

Redwood's ramp-up is also crucial as the auto industry races to comply with this summer's massive climate law, which requires that car companies source and build certain percentages of their EVs domestically if they want their vehicles to qualify for tax credits.

But even without federal encouragement, the industry has worked to bring the various parts of the all-new EV battery supply chain to the US in order to drive down materials costs, and cut the sticker price for buyers.

With more and more demand for the materials to make these things, taking advantage of recycling can ease a supply crunch and eventually drive down costs. The more materials the industry can put back into the supply chain, the better.

Redwood takes the work a step further than many recyclers by next, remanufacturing the materials.

"The goal is to make the most sustainable battery materials," said Jackson Switzer, Redwood senior director of business development and one of Insider's 100 People Transforming Business. "To make the most sustainable battery materials, we need to get as much recycled nickel, cobalt, and lithium as we can into the front end of the system. You've got to scale the front end of the system, which is effectively, recycling."

Ford established its BlueOval City campus in Tennessee and two battery plants in Kentucky. GM, through its Ultium Cells joint venture with LG Energy Solution, is also investing in battery-making in Tennessee. Panasonic is building a new battery factory in Kansas. Hyundai is investing in EVs and battery production in Georgia.

Redwood's ramp-up is also crucial as the auto industry races to comply with this summer's massive climate law, which requires that car companies source and build certain percentages of their EVs domestically if they want their vehicles to qualify for tax credits.

But even without federal encouragement, the industry has worked to bring the various parts of the all-new EV battery supply chain to the US in order to drive down materials costs, and cut the sticker price for buyers.

With more and more demand for the materials to make these things, taking advantage of recycling can ease a supply crunch and eventually drive down costs. The more materials the industry can put back into the supply chain, the better.

Redwood takes the work a step further than many recyclers by next, remanufacturing the materials.

"The goal is to make the most sustainable battery materials," said Jackson Switzer, Redwood senior director of business development and one of Insider's 100 People Transforming Business. "To make the most sustainable battery materials, we need to get as much recycled nickel, cobalt, and lithium as we can into the front end of the system. You've got to scale the front end of the system, which is effectively, recycling."

No comments:

Post a Comment