Ex-Fortescue Executives Unveil Innovative Green Iron Startup

Admin 1 Day Ago

Former executives from Fortescue’s clean energy initiatives, Michael Masterman and Bart Kolodziejczyk, have initiated a startup focused on reducing carbon emissions in the Australian iron ore sector. Notably, their approach differs from the hydrogen and membrane technology endorsed by their previous employer.

Having secured $10 million in seed funding this week, primarily from venture capital firm Playground Global, the partners express their readiness to sponsor research and development in green materials at their newly established company, Element Zero.

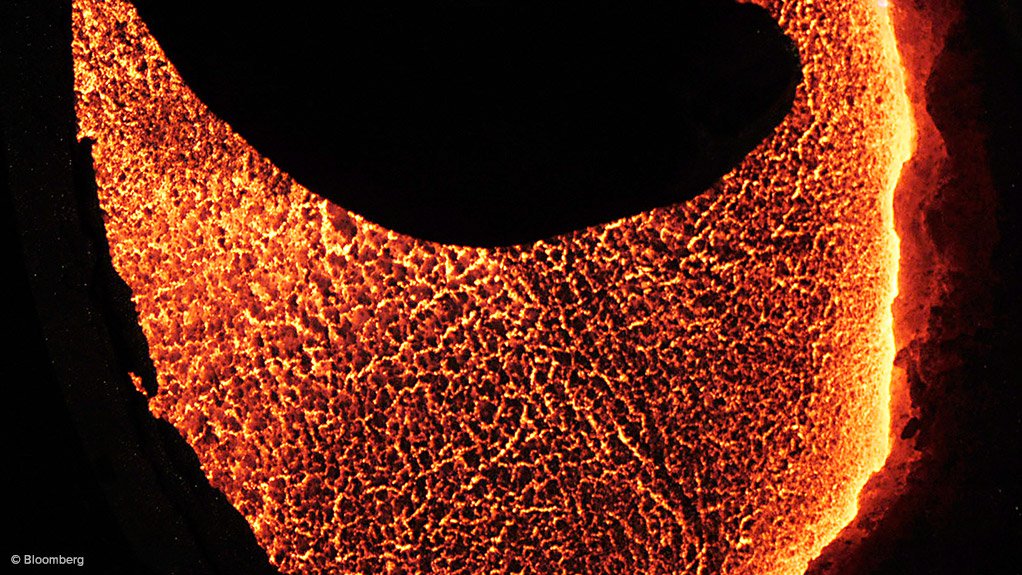

Through Element Zero’s patented electro-reduction method, the startup is already transforming iron ore into “green iron” on a laboratory scale. By utilizing an alkaline solution and electric current, this method effectively separates pure iron from the waste products present in the ore.

According to the founders, Element Zero’s patented process is particularly suitable for the prevalent hematite ores dominating the Australian iron ore industry. Furthermore, it exhibits versatility, as the method can be applied to other metals, such as nickel.

Strategically situated in Perth and northern Western Australia, Element Zero benefits from its proximity to the world’s largest iron ore ports, responsible for exporting approximately 55% of the globe’s seaborne iron ore supply.

With plans to generate 5 million tonnes per year of iron ore feed, resulting in the production of around 2.7 million tonnes of high-purity iron, Element Zero is poised to make a significant impact.

Founder and CEO Michael Masterman emphasized the groundbreaking nature of their processing platform, stating, “Our processing platform will, for the first time, allow cost-effective and scalable production of carbon-free metals crucial to the iron and steel and critical metals industries.”

Highlighting the comprehensive support received from Playground Global, Masterman shared ongoing discussions about developing green iron and green silicon value chains in the United States. Collaboration is also underway with major iron ore miners and iron and steel companies on a global scale.

Element Zero’s modular approach aims to address 8% of global carbon dioxide emissions from iron and steelmaking, positioning the company as a key player in environmental sustainability. Currently, the company is in the process of commissioning a green iron pilot plant in the Perth suburb of Malaga, with plans to feed 100 kg of iron ore into the process daily.

Startup aims to transform WA from world’s mine into world’s foundry

19th January 2024

By: Mariaan Webb

Creamer Media

Senior Deputy Editor Online

Perth-headquartered Element Zero, a green materials platform company launched by former Fortescue executives, has raised $10-million in seed funding for its pioneering zero-carbon metal conversion technology.

The funding, led by Playground Global, will be used to grow research and development, engineering and project development teams and scale the development of a pilot iron plant.

Cofounded by former Fortescue Future Industries CFO and chief investment officer Michael Masterman and former Fortescue Metals Group chief scientist Bart Kolodziejczyk, Element Zero has created a low-temperature mineral processing platform that uses renewable energy to convert iron-ore to iron.

“Our processing platform will, for the first time, allow cost-effective and scalable production of carbon-free metals crucial to the iron and steel and critical metals industries,” said Masterman.

The non-aqueous electrochemical process allows Element Zero to process the full spectrum of iron ores; this includes the core 95% of Australian and Brazilian global trade in iron-ore. Currently, lower grade iron-ore cannot be processed using hydrogen-fed direct iron reduction or other lower carbon processing technologies.

Element Zero said the technology had been tested successfully on iron-ore, nickel, and other future-facing metals. The lower temperature also allows Element Zero to run this process on intermittent renewables like wind, solar and hydropower.

Based adjacent to the largest iron-ore ports in the world, responsible for exporting nearly 55% of the world’s seaborne iron-ore supply, Element Zero plans to develop five-million tonnes a year of iron-ore feed, producing about 2.7-million tonnes of high purity iron.

“Element Zero will help transform Western Australia from the world's mine into the world's foundry, dramatically reducing carbon emissions in the process,” said Playground Global cofounder Peter Barrett, who has joined the Element Zero board.

“Australia is poised to become a leader in resilient and sustainable global prosperity – its natural wealth in minerals and renewable energy, blended with innovation in electrochemistry and new materials, will cement its leadership in the energy transformation. Element Zero is a major catalyst in this shift and the Pilbara region in the north of Western Australia stands as the premier location globally to showcase the company’s potential,” added Barrett.

Perth-headquartered Element Zero, a green materials platform company launched by former Fortescue executives, has raised $10-million in seed funding for its pioneering zero-carbon metal conversion technology.

The funding, led by Playground Global, will be used to grow research and development, engineering and project development teams and scale the development of a pilot iron plant.

Cofounded by former Fortescue Future Industries CFO and chief investment officer Michael Masterman and former Fortescue Metals Group chief scientist Bart Kolodziejczyk, Element Zero has created a low-temperature mineral processing platform that uses renewable energy to convert iron-ore to iron.

“Our processing platform will, for the first time, allow cost-effective and scalable production of carbon-free metals crucial to the iron and steel and critical metals industries,” said Masterman.

The non-aqueous electrochemical process allows Element Zero to process the full spectrum of iron ores; this includes the core 95% of Australian and Brazilian global trade in iron-ore. Currently, lower grade iron-ore cannot be processed using hydrogen-fed direct iron reduction or other lower carbon processing technologies.

Element Zero said the technology had been tested successfully on iron-ore, nickel, and other future-facing metals. The lower temperature also allows Element Zero to run this process on intermittent renewables like wind, solar and hydropower.

Based adjacent to the largest iron-ore ports in the world, responsible for exporting nearly 55% of the world’s seaborne iron-ore supply, Element Zero plans to develop five-million tonnes a year of iron-ore feed, producing about 2.7-million tonnes of high purity iron.

“Element Zero will help transform Western Australia from the world's mine into the world's foundry, dramatically reducing carbon emissions in the process,” said Playground Global cofounder Peter Barrett, who has joined the Element Zero board.

“Australia is poised to become a leader in resilient and sustainable global prosperity – its natural wealth in minerals and renewable energy, blended with innovation in electrochemistry and new materials, will cement its leadership in the energy transformation. Element Zero is a major catalyst in this shift and the Pilbara region in the north of Western Australia stands as the premier location globally to showcase the company’s potential,” added Barrett.

No comments:

Post a Comment