ALTERNATIVE FUELS

Smyril Line Signed Contracts for Environmentally Friendly RoRo Cargo Ships

[By: Smyril Line]

Smyril Line is pleased to announce that a contract has been made with the CIMC Raffles shipyard in China to build two new cargo ships for the company. These are two identical RoRo ships, measuring 190 meters in length and having 3,300 lane meters for trailers. The new cargo ships will join Smyril Line's current network, and they are planned to start sailing in 2026. The ships are designed for optimal year-round seaworthiness in the North Atlantic with great emphasize on our crew comforts and wellbeing on board.

The ships are being designed in close cooperation with Knud E. Hansen, naval architects, who, together with the extensive experience of Smyril Line in the North Atlantic, will ensure that the ships are built for the special route between Europe, the Faroe Islands, and Iceland. The ships will be modern and environmentally friendly, meeting all international emission standards. Compared to the company's existing fleet, they will emit significantly less per transported ton. At the same time, the ships will be equipped with a battery system and the possibility for shore power, which means that port operations can be conducted without emissions. The ships will also be prepared to sail on e-methanol, which is considered to be the best future choice for green energy at Smyril Line.

"Now is the time to set ourselves new and bigger goals towards reducing emissions in the North Atlantic," says Jens Meinhard Rasmussen, CEO of Smyril Line. "The company's main goal is to ensure safe and reliable transportation of both passengers and cargo, and to connect the periphery of the North Atlantic with the rest of the world. With the new ships, we emphasize futureproofing and leading the company towards a greener energy solution and lead the way for Smyril Line towards the goals for decarbonization in our fleet renewal, supporting the green transition of the shipping industry. We will also transport much larger quantities of cargo with less energy consumption than we do now. The energy saving will be at least 60%. This is an important step for us to achieve our goals towards net-zero emissions by 2050, while we can offer our customers an even better service. We have been operating routes in the North Atlantic since 1982. This is not just one of the world's longest ro-ro and ro-pax routes, but probably also the one with the most challenging sailing conditions. We know from experience that sailing on our route places great demands on both ship and crew, and we have therefore designed the ships with this in mind."

The products and services herein described in this press release are not endorsed by The Maritime Executive.

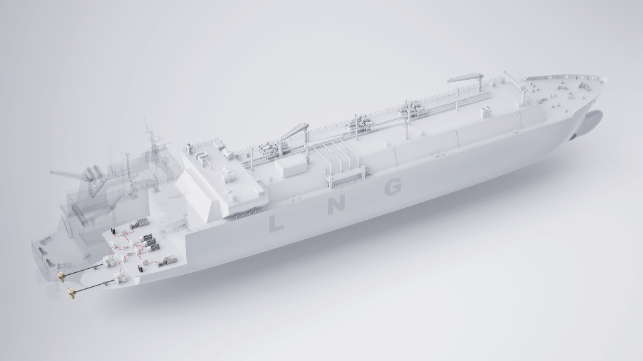

DNV Study Validates Energy Efficiency Gains for LNG Carriers

[By: ABB]

DNV has quantified the gains that owners of liquefied natural gas (LNG) carriers could expect to achieve using the new Dual Fuel, Electric+ (DFE+) solution developed by ABB and MAN Energy Solutions. Comprising MAN’s four-stroke 49/60DF dual fuel engine and ABB’s Dynamic AC power distribution and control system, the solution has been developed to overcome efficiency challenges that are specific to the vessel type.

DNV’s Maritime Advisory assessment concludes that the DFE+ concept is “a competitive and more energy efficient alternative to even the most efficient conventional dual-fuel LNG carrier propulsion designs.” Smaller machinery space requirements could deliver “a conservative estimate” of 5 percent greater cargo capacity. Combined with other steps to optimize performance, the DFE+ concept could contribute to overall energy savings of 6 – 7.5 percent considering the ship’s increased transport work, DNV says.

From January 1, 2023 the International Maritime Organization (IMO) has required shipowners to report vessels into an Energy Efficiency Design Index (EEDI), an Energy Efficiency Existing Ships Index (EEXI) and an operational Carbon Intensity Index (CII). These tools benchmark ships so that owners know what they must do to meet IMO targets for reducing greenhouse gas emissions.

As the newest addition to MAN’s four-stroke portfolio, the MAN 49/60DF engine is optimized for LNG. It is also highly compatible with ABB’s Dynamic AC system, which combines the merits of conventional AC with those of variable frequency to allow the engines to operate on optimal speeds – significantly improving total fuel consumption.

"Owners of LNG carriers face specific challenges in complying with the regulations, given their reliance on propulsion solutions with limited potential for efficiency gains," said Prof. George Dimopoulos, Scientific Advisor, DNV. "The ABB – MAN propulsion concept aims to offer a highly effective way for LNG carriers to meet progressively tightening emissions regulations while also reducing fuel costs."

“With the current global orderbook for LNG carriers including more than 200 vessels, and emission regulations continuing to tighten, owners need new technologies to meet the requirements that apply to this specific class of ships,” said Rune Lysebo, Strategic Market Development, ABB Marine & Ports. “DNV’s testimony on the gains available to LNG Carriers with the new solution developed by ABB and MAN Energy Solutions proves the time is right to explore the next-generation technologies for this vessel type.”

DFE+ could be installed with an energy storage solution to operate as a spinning reserve or come coupled with ABB’s Azipod® electric propulsion. ABB and MAN will also explore integrating fuel cells as the technology matures.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Hydrogen-Powered Inland Cargo Barge Ready to Sail on the Rhine

The retrofit has been completed and a new hydrogen-powered cargo barge is now ready to begin operations on the Rhine sailing between Rotterdam in the Netherlands and Duisburg in Germany. Dutch shipowner Future Proof Shipping (FPS), the EU-funded Flagships project, and the Interreg-funded ZEM Ports NS project celebrated that milestone in a project that they believe will serve as a model for the industry.

“This is another proud moment for us, it proves moving cargo with zero emissions and zero impact is not only possible, it’s scalable too,” said Richard Klatten, CEO of Future Proof Shipping. “Successfully launching our second hydrogen-powered inland cargo vessel is just as important an achievement as the first, not just for Future Proof Shipping, ZEM Ports NS, and the Flagships project, but for the future of green shipping.”

FPS announced its plans for the conversion of the two barges in 2021 and working with partners including Holland Shipyard Group´s Werkendam facility, just outside Rotterdam, overcame key hurdles to bring the ships to service. The first barge was completed in May 2023 with the plan calling for the vessel to operate between Rotterdam and Antwerp. It is chartered to BCTN Network of Inland Terminals on behalf of Nike EMEA. The company has said its plan is to put 10 inland and short-sea vessels into service in the five years.

The H2 Barge 2 is the first of two demonstrators in the EU-funded Flagships project, and the second demonstrator of the ZEM Ports NS project. The vessel, formerly Fenny 1 and FPS Waal, was built as a conventionally powered containership. It is 360 feet (110 meters) in length with a capacity of approximately 200 TEU.

During 2023, H2 Barge 2 was stripped of all combustion engines and fossil fuel tanks by Holland Shipyards Group after reaching the yard in August. Now, the vessel has a completely emission-free propulsion system including PEM fuel cells, hydrogen storage, battery packs, and an electric drive train installed below deck. Six fuel cells from Ballard Power Systems raise the total power installed to 1.2 MW. H2 Barge 2 is expected to reduce 3,000 tonnes of CO2 annually when sailing the Rhine.

“Inland waterways are important for freight transport in Europe,” said Mirela Atanasiu, Executive Director ad interim of Clean Hydrogen Partnership. “We are thrilled to see a high-power container vessel being converted to zero-emission. The H2 Barge 2 will bring knowledge on how to retrofit vessels from diesel combustion to zero-emission alternatives, by using batteries in combination with green hydrogen in a fuel cell.”

The second demonstrator vessel in the Flagships project, Zulu 06, will be deployed in Paris in 2024.

“We´ve been working hard for several years to get to this point. Having the first demonstrator on the Rhine is truly a great achievement by Future Proof Shipping and the rest of the partners. The aim of the Flagships project is to take zero-emission waterborne transport to an entirely new level. Now we´re one important step closer to reaching our goal,” says Flagships Project Coordinator and Senior Scientist at VTT, Jyrki Mikkola.

The project was made possible with funding support from the Interreg North Sea Region Programme (Zero Emission Ports North Sea – ZEM Ports NS), Flagships H2020 Project (Clean Hydrogen Partnership), and Netherlands Enterprise Agency (RVO).

No comments:

Post a Comment