Feb. 25, 2024

A lab sample of the finished vitrification product, minus the radioactive material, at Bechtel offices in Richland on Feb. 8. (Kevin Clark / The Seattle Times)

By Esmy Jimenez

Seattle Times staff reporter

Fifty-five million gallons of radioactive waste.

A decadeslong timeline reaching easily into 2070.

A complex assembly involving several state and federal agencies, private contractors, tens of thousands of workers, local residents, and advocates all invested in a colossal effort, estimated to be the largest nuclear cleanup project in the world.

The Hanford site in Benton County is at a pivotal moment, set to finally transform the nuclear leftovers of a century past into glass that can be safely stored — a process called vitrification. Last October, the first of two melters used to actually vitrify the waste became active, with the second melter scheduled to launch this spring.

The project’s success — or failure — will ultimately influence the future of a dilemma that has long plagued the Northwest and the U.S.

“They’re doing something out there that has never been done before,” said Nikolas Peterson, the executive director of Hanford Challenge, a nonprofit watchdog.

“I think I have to constantly remind myself of that even when I’m critical of the facility.”

For staff at the Pacific Northwest National Laboratory, who are developing and testing the glass formulations, this moment in time feels significant.

“It’s really exciting to see how far it’s come,” said Tom Brouns, the lead of the environmental manager sector at PNNL, who’s worked at Hanford for more than 30 years.

“It’s taking a long time but it’s so close.”

How it works

Vitrification is not a new technology. The same process is used in making pottery, where high heat is applied to a material that leads to metamorphosis of the original substance.

Researchers in France have studied the vitrification of nuclear waste going back to the 1950s, and the country successfully built several facilities to tackle cleanup. Within this specialized industry, it’s considered one of the best methods to stabilize waste — it’s expensive but performs well over long periods of time (hundreds or thousands of years) and is an international standard when it comes to managing waste with high levels of radioactivity.

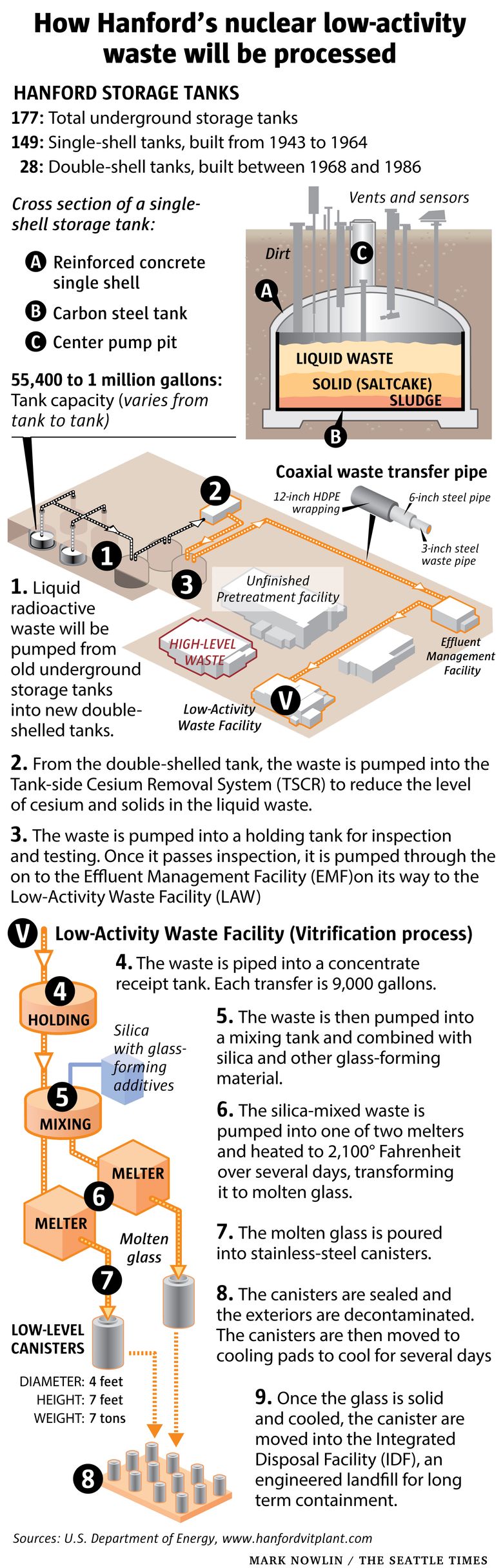

The process to vitrify waste at Hanford is highly complex and involves multiple steps.

It starts with a removal system that separates high-level waste that’s more toxic and radioactive from low-activity waste that is simpler to process and store. According to a 2023 report from the U.S. Government Accountability Office, about 95% of the waste in storage tanks is low activity when it comes to the physical volume. High-level waste only comprises about 5% of the volume but more than 70% of the radioactivity.

Separating the waste is crucial to better management, treatment and disposal.

This low-activity waste is pumped to a separate holding tank that then is pumped into another tank for mixing. Silica (a material commonly used to make sand) along with other additives are added to create the material that will ultimately be glass.

That mixture is pumped into melters, giant 300-ton devices that are the “heart” of the vitrification process. These burn at 2,100 degrees Fahrenheit and will create a molten substance over several days. It’s poured into stainless steel canisters where it eventually cools enough to become solid glass.

“Glass is a superior matrix,” Brouns explained. “Because the radio nuclei actually get trapped in the chemical matrix of the glass. Literally, they’re part of the atom.”

Frit, glass beads used in the vitrification process to solidify radioactive material, at Bechtel offices in Richland on Feb. 8. (Kevin Clark / The Seattle Times)

Over email, a spokesperson for the U.S. Department of Energy shared that so far, “The [Waste Treatment and Immobilization Plant] team has successfully filled four stainless steel containers with molten test glass.”

It’s all part of a slow but steady process to monitor for safety and environmental compliance as Hanford prepares to fully begin the active vitrification process starting next year.

The decision to vitrify the waste in Hanford’s 177 storage tanks goes back to what’s known as the Tri-Party Agreement, a legal agreement and consent order between the U.S. Department of Energy, the Environmental Protection Agency and Washington’s Department of Ecology. This agreement lays out the responsibilities of each agency when it comes to cleanup efforts and timelines, and ultimately tries to ensure that federal laws governing the disposal of solid waste and hazardous waste are followed.

Eventually, vitrified low-activity waste will be disposed of on-site in stainless steel casks, and a separate melter just for high-level waste will come online to manage the most toxic waste. That glassified product will go to a deep geological repository, though at this point, the U.S. does not have such a site.

Hanford’s history

Hanford’s origin traces back to the 1940s as part of World War II efforts to produce plutonium for a nuclear weapon as part of The Manhattan Project.

It was the world’s first nuclear production plant, though most workers were in the dark about their contributions. The materials produced on site were part of the atomic bomb that was later dropped on the people of Nagasaki, Japan.

Central Washington’s desert terrain was selected as a site due to its proximity to the Columbia River and its low population count.

The site kept producing plutonium through the Cold War, and in 1987 the last reactor was shut down. Over the nearly four decades since, officials have developed a plan to clean up the waste, as many of the tanks that hold nuclear waste have outlived their original life spans, leaking waste into the surrounding area.

This pollution has led Hanford to be categorized as a Superfund site: one of four areas on the EPA’s national priorities list for cleanup.

“This is a multigenerational process,” Brouns said. “It’s going to take longer to clean it up than it took to produce the waste in the first place.”

Two melters are installed, with one in operation, at the Low-Activity Waste Facility in the Hanford Vit Plant near Richland on Feb. 8.

\ (Kevin Clark / The Seattle Times)

Part of the challenge has been the collaboration among several state and federal agencies and shifting the culture from one devoted to the creation of nuclear materials, often mired in secrecy and urgency, to a new movement devoted to cleanup.

It’s also led to discussions of who’s footing the bill and how that’s affecting the timeline, pushing the goal post further and further into the future.

We need your support

In-depth journalism takes time and effort to produce, and it depends on paying subscribers. If you value these kinds of stories, consider subscribing.

Subscribe

GAO‘s report estimated the total cost of Hanford’s cleanup to be around $341 billion, with completion estimated for 2084.

“Historically, what’s happened is Hanford has been kind of routinely underfunded by like 700 million to a billion dollars or so,” said Ryan Miller, a spokesperson for the nuclear waste program at the Washington Department of Ecology.

Last year, President Joe Biden’s budget requested a record amount for Hanford dollars, at $3 billion. State officials hope for the same this year.

According to Ecology, every year of inadequate funding delays cleanup an additional 1½ to 3 years.

One of the greatest concerns for environmental advocates is a cheaper option that’s been floated by some federal agencies, called grouting, which involves solidifying the waste in specialized concrete.

This could cut costs and potentially shorten the cleanup timeline, but it’s less stable than vitrification and does not last as long.

For Peterson from Hanford Challenge, vitrification is key.

“Nobody wants to see this process fail,” Peterson said.

Part of the challenge has been the collaboration among several state and federal agencies and shifting the culture from one devoted to the creation of nuclear materials, often mired in secrecy and urgency, to a new movement devoted to cleanup.

It’s also led to discussions of who’s footing the bill and how that’s affecting the timeline, pushing the goal post further and further into the future.

We need your support

In-depth journalism takes time and effort to produce, and it depends on paying subscribers. If you value these kinds of stories, consider subscribing.

Subscribe

GAO‘s report estimated the total cost of Hanford’s cleanup to be around $341 billion, with completion estimated for 2084.

“Historically, what’s happened is Hanford has been kind of routinely underfunded by like 700 million to a billion dollars or so,” said Ryan Miller, a spokesperson for the nuclear waste program at the Washington Department of Ecology.

Last year, President Joe Biden’s budget requested a record amount for Hanford dollars, at $3 billion. State officials hope for the same this year.

According to Ecology, every year of inadequate funding delays cleanup an additional 1½ to 3 years.

One of the greatest concerns for environmental advocates is a cheaper option that’s been floated by some federal agencies, called grouting, which involves solidifying the waste in specialized concrete.

This could cut costs and potentially shorten the cleanup timeline, but it’s less stable than vitrification and does not last as long.

For Peterson from Hanford Challenge, vitrification is key.

“Nobody wants to see this process fail,” Peterson said.

No comments:

Post a Comment