Need for New Safety Rules for Methanol-Fueled Vessels, Advises Survitec

[By: Survitec]

A new fire safety study by global Survival Technology solutions provider Survitec has revealed that existing fire-fighting methods used to extinguish machinery space spray and pool fires on conventionally fueled vessels are inadequate when dealing with methanol-based fires.

This follows extensive comparative fire tests on dual-fuel marine engines using diesel oil (DO) and methanol, carried out amid growing interest in methanol as an alternative marine fuel.

“Our tests confirm that traditional water mist fire suppression mechanisms do not perform as expected on methanol pool fires and methanol spray fires. A completely different approach is required if these ships are to remain safe,” said Michal Sadzynski, Product Manager, Water Mist Systems, Survitec.

Methanol is a methyl alcohol (CH3OH) that burns in a completely different way than hydrocarbon fuels and has a much lower flashpoint of 12°C (54°F). However, while there are established fire safety regulations and testing standards for diesel fuels, clear test protocols for alcohol-based fuels such as methanol and ethanol have yet to be developed.

“We believe this is a high-risk situation that needs immediate action,” stressed Sadzynski. “Methanol fires are far more aggressive than fires involving traditional hydrocarbon fuels. Methanol fires have different physicochemical properties and so they cannot be extinguished as easily or with the same approach.”

The Survitec tests found that while water mist systems are highly effective in absorbing heat and displacing oxygen on diesel fires, they do not produce the same results on methanol fires.

“We had to completely rethink nozzle placement, spacing and other factors to make water mist suppression effective on methanol. For instance, the range for nozzle installation height is much lower than that needed to put out a diesel fire,” he said.

This finding indicates that if existing vessels are retrofitted to run on methanol, they would need to overhaul and redesign their fixed fire-fighting arrangement completely.

For bilge areas, statutory rules formulated in IMO MSC.1/Circ.1621 establish a requirement for an approved alcohol-resistant foam system for ships running on methanol. For the first time, a fixed, low expansion foam system is mandatory under the rules when it comes to protecting machinery space bilges.

"Our tests demonstrate that standard discharge devices do not properly extinguish methanol pool fires in the confined bilge space. It is crucial to deliver properly expanded foam on the methanol pool fire and this is not an easy task within such a narrow space where throw length is limited,” said Maciej Niescioruk, Product Manager, Foam Systems, Survitec.

He said, “MSC.1/Circ.1621 provides us with a starting guideline but it is very general and therefore open to interpretation. Moreover, methanol compliance for Local Application Firefighting (LAFF) systems is not yet covered. As an industry, we need to come together and develop comprehensive and robust fire test standards and safety rules tailored to methanol's unique properties.”

The stark conclusion of the investigation arrives at a time of increasing orders for methanol-fueled ships. The greener fuel is seen as a panacea to meeting the industry’s emissions abatement targets, and forecasts predict accelerated adoption rates.

Orders for methanol-fueled newbuilds increased by 9% in the last 12 months, 2% more than those for LNG-fueled ships. Analysts suggest the methanol-fueled fleet will account for 20mgt by 2028.

“We are seeing a significant uptake in orders for methanol-fueled vessels, with 2023 being the breakout year for this alternative marine fuel. With more methanol-powered ships being built every year, the industry must act now to prevent dangerous gaps in fire safety," said Niescioruk.

“We encourage all stakeholders to come together to address methanol's unique fire risks and create clear standards, new testing protocols and updated safety rules for methanol.”

The products and services herein described in this press release are not endorsed by The Maritime Executive.

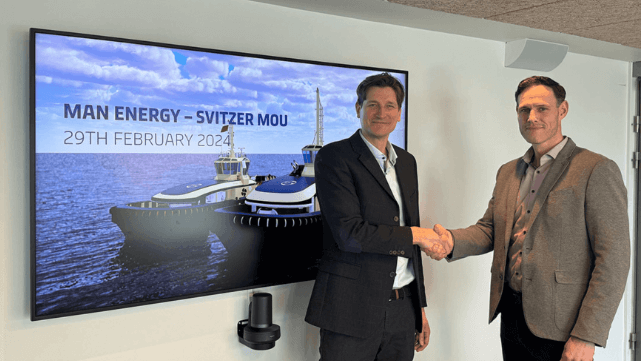

Svitzer Targets Methanol-Fueled MAN 175DF-M Engine for Tug Application

[By: MAN Energy Solutions]

MAN Energy Solutions and Svitzer have signed a Memorandum of Understanding (MoU) focused on the development of a methanol-fuelled version of the MAN 175D engine. Designated 175DF-M (Dual Fuel-Methanol), the MoU targets the finalisation of a field-test agreement based on which a dual-fuel engine and plant equipment will be installed on board one of Svitzer’s newbuild tugs.

Kasper Karlsen, Chief Operating Officer at Svitzer, said: “At Svitzer, we’ve set ambitious yet realistic, long-term targets to decarbonise our operations. In 2023 alone, we reduced the CO2 intensity of our global fleet by 24% and we’re committed to making further progress through the use of low-carbon fuels like methanol, innovative engine technologies, and continuous changes of behaviour. The MoU signed with MAN represents an exciting opportunity to jointly secure valuable field experience focusing on the use of dual-fuel methanol engines within our fleet.”

Svitzer has a long-standing relationship with MAN Energy Solutions, especially recently with the MAN 175D engine. In 2023, Svitzer selected the high-performance MAN 175D engines for its new TRAnsverse tug design.

Ben Andres, Head of Medium- and High-Speed, MAN Energy Solutions, said: “We are very happy to enter into this agreement with such a high-profile operator as Svitzer. We are convinced that Svitzer is the right partner to start this common project with because we both have highly ambitious goals for decarbonisation and to maximally reduce our CO2 footprint. We therefore welcome this excellent opportunity to continue our cooperation with such an important 175D customer and look forward to the benefits it will bring for both parties.”

Alexander Knafl, Senior Vice President, MAN Energy Solutions, said: “Svitzer has been working on its own low-emission concept for some time and this agreement brings this to the next level. Thus, the agreed timeline serves both companies’ targets very well. Svitzer’s tug operation is an excellent candidate for the field-testing of our newly developed MAN 175DF-M engine and I look forward to a close collaboration.”

The next phase leading to the signing of the field-test agreement will focus on details of the fuel-supply system, engine-room design, exhaust after-treatment and engine-performance optimisation.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

PowerCell Group Joins in on Hydrogen Fuel Cell Infrastructure Demonstration

[By: PowerCell Group]

Project partners Port of Gothenburg, Skanska, PowerCell Group, Hitachi Energy, Linde Gas, Volvo Group and Skagerak Energy have conducted a joint field test to demonstrate the latest innovation in hydrogen-electric power infrastructure: the containerized Hyflex solution.

PowerCell Group, a global leader in hydrogen-electric solutions with unique fuel cell stacks and systems, has partnered with Hitachi Energy, a global technology leader in promoting sustainable energy, to develop a new product called Hyflex. The product is a flexible container solution that can be used in a wide range of applications for emission-free power production. Hyflex uses a 100kW hydrogen fuel cell from PowerCell in combination with batteries to generate power independently of the grid without emitting greenhouse gases when using green hydrogen. From March 4th-17th in the Port of Gothenburg, the project partners demonstrated that the solution is ready to replace fossil fuel solutions today in real life operations.

The trial was focused on off grid power generation for construction sites and vehicles, but the technology also has potential port applications, specifically with marine shore power connections (cold ironing) in mind.

When docked at port, ships remain predominantly powered by auxiliary engines to provide energy while the main engines are shut down. These auxiliary engines are typically powered by polluting oil-based fuels. Therefore, the development of more, and more sustainable shore power connections is key to reducing GHG emissions in ports.

Richard Berkling, CEO of PowerCell Group, commented: “The green transition is underway, with hydrogen-electric solutions increasingly commercially valid for replacing fossil fuels in power generation - with demand for industrialised solutions supporting decarbonisation growing. At PowerCell, we see that the hydrogen industry is beyond the tech exploration stage and we are delivery emission-free fuel cell products to our customers. This makes us well-prepared and ready to be an enabler of the technology shift in the industry.

“The Hyflex has the potential to replace diesel generator sets across multiple platforms, as well as taking on new power generation applications. The current demonstrator has been developed with construction sites in mind, however we also recognise the need for marine and port electrification applications, such as sustainable ship-to-shore power.”

From a marine perspective, the demonstrator project is well-timed with the European Union’s latest regulations. Under FuelEU Maritime, it will be obligatory for passenger and container ships to use shore power supplies for all electricity needs while moored in major EU ports as of 2030, with a view to mitigating air pollution in ports, which are often close to densely populated areas.

Sustainable shore power connections lower ships’ total GHG emissions and eliminate the local emissions of sulphur oxides (SOx), nitrogen oxides (NOx), and particulate matter such as black carbon that ships burning oil-based fuels produce. Importantly, this improves local air quality and supports the respiratory health of nearby residents, port workers, passengers and crew.

Hydrogen and fuel cells can also deliver an independent ‘off grid’ energy source; adding a layer of resilience, if – for example – the grid is unstable or goes down. Hydrogen fuel cells are a strong option for shore power connections as they align well with the hydrogen infrastructure that many ports are already implementing or have planned.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

No comments:

Post a Comment