ALTERNATIVE FUELS

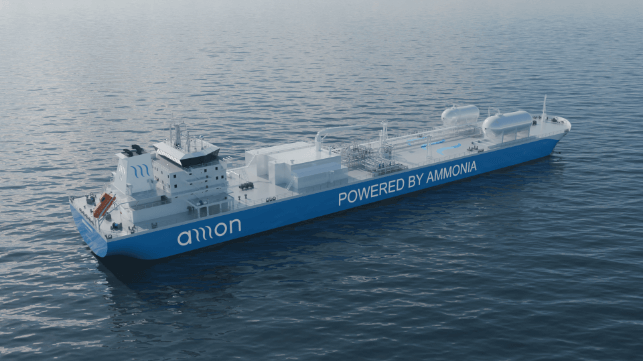

Amon Maritime Launches Amon Gas with NOK 18 Million Grant from ENOVA

[By: Amon Maritime]

The grant was awarded at a ceremony hosted by the Norwegian minister of climate and the environment together with ENOVA at DNV HQ at Høvik.

“This is a significant milestone towards realizing carbon free transportation systems within the gas carrier segment. Amon Gas will provide the market with low-emission vessels while simultaneously meeting customer demands with innovative solutions.” says André Risholm, CEO Amon Maritime

Amon Gas is targeting a shipbuilding series starting with 2 firm orders of ammonia- powered MGCs with a goal of being in operation by 2028.

The vessels are designed to use ammonia as fuel, for both propulsion and power consumption, also when transporting LPG as cargo and incorporates the best energy-saving measures.

MGC is a large vessel type with high fuel consumption. This means that the climate impact per ship by switching to ammonia as fuel will be significant. Carbon emission calculations give an estimated 87% reduction compared to conventional vessels from the start of operations, with ambitions for further reductions towards 100%.

Amon Maritime CTO, Steinar Kostøl, explains:

- If ammonia is the fuel of the future, it will lead to a high growth in sea transport of ammonia. Ammonia is primarily transported on MGCs today.

- If the ship transports ammonia, the "chicken-and-egg" dilemma of making bunkering available is avoided—the substance is already on board as cargo.

- Because the ship is already designed for transporting ammonia, the relative additional cost in this segment compared to conventional ships will be less than in most other segments.

SRC and GREEN MARINE Join Forces to Bring Methanol Superstorage to Market

[By: SRC Group]

SRC Group and GREEN MARINE have signed a collaborative agreement which brings two of the strongest advocates of methanol as a marine fuel together to develop and deliver Methanol Superstorage to market.

The cooperation aims to realise benefits available to SRC’s Methanol Superstorage solution, which has been turning heads among owners, builders, repairers, class societies and insurers since its launch. Using the SPS Technology Sandwich Plate System instead of traditional cofferdams that separate tank walls, Methanol Superstorage boosts shipboard tank volumes by 85% and provides effective mitigation for methanol’s significantly lower energy density than conventional HFO.

Independent advisory and project management firm GREEN MARINE has built an unrivalled track record for delivering methanol transition solutions for all ship segments. With a pedigree reaching back to the first use of methanol as a marine fuel, its services cover ship design, yard selection, construction supervision, technical management and operations, training, procurement, sales and bunkering, GREEN MARINE is involved in the majority of methanol-related ship projects in the world today.

“Following the huge initial impact made by Methanol Superstorage, SRC and GREEN MARINE will work together to provide comprehensive technical coverage for methanol integration,” said Hannes Lilp, CEO, SRC Group. “With GREEN MARINE’s extensive experience in methanol projects and overall technical knowledge of the entire process, combined with SRC’s expertise in methanol storage and over 23 years of experience in ship refits and conversions, we are well-placed to onboard Methanol Superstorage for both retrofit and new build vessels, and establish a mature sales framework to enable global adoption.”

GREEN MARINE continues to drive development of the methanol supply chain in the marine market, with recent agreements including preparations for projected supplies of green methanol from Chinese partners. The firm also recently named Singapore-based former Methanol Institute Chief Commercial Officer, Chris Chatterton as Managing Director & Partner, with effect from 1st July, 2024.

Chatterton commented: “Market receptiveness to Methanol Superstorage has been exceptional and we look forward to working with SRC to realise its extraordinary potential to help drive forward methanol as a mainstream marine fuel. Investors will be encouraged to know that, as the most experienced technical player in marine methanol, GREEN MARINE’s expertise, insight and global support stands alongside SRC in the demonstration phase of Methanol Superstorage.”

Methanol Superstorage has already received Approval in Principle from a leading IACS society, which indicates that no conceptual issues have been identified relating to ship regulatory requirements. “In parallel to class approvals, SRC and GREEN MARINE will also oversee and manage 3rd Party technical development” said Lilp.

Norway Provides Record Funding for Ammonia and Hydrogen Vessel Projects

Enova, the Norwegian government’s clean energy fund developed to spur decarbonization efforts including in the maritime sector, is making its largest-ever awards. The latest competition round will provide approximately $114 million in support for a total of fifteen ships. Six of the vessels will be ammonia-fueled while nine will be cutting-edge hydrogen projects, including five dry bulk newbuilds for Maris Fiducia and the charter market.

The awards are going to Hoegh Autolines which is building a new class of the world’s largest car carriers with the last four slatted for dual-fuel ammonia propulsion. Amon Gas was also awarded for an ammonia project. The Norwegian division of Dutch shipowner Maris Fiducia, as well as Møre Sjø, Napier, and Halten Bulk, are all being awarded grants for hydrogen vessels.

Maris Fiducia announced plans for its project which will include five 6,000 dwt vessels designed by the Dutch firm Ankerbeer. The hull design is being optimized for efficiency and low fuel consumption.

The power plant will be a dual-fuel hydrogen ICE combined with fuel cells for auxiliary power. In addition to the ICE plant, they will be equipped with a Zero Emission Pod, a module containing a complete hydrogen energy system that is being developed and tested by Norway-based HAV Hydrogen. The company is currently developing its first full-scale pods, which will be ready for testing by 2025. They anticipate having them available by the end of 2025.

Maris Fiducia will build five hydrogen-fueled vessels for the charter market (Maris Fiducia)

Each of the ZEPODs is expected to deliver a total capacity of 400 kW, which will be enough to run all the auxiliary systems on the bulk carriers. They expect to be able to upgrade the ZEPODs to a 1 MW capacity at a later date.

Maris Fiducia notes that the technology is advancing rapidly. Just over a year ago, they said they were inspired to based on the fuel availability and emerging technical competence to pursue this concept. Enova awarded over $28 million in support for the project.

“This brings us another step closer to the commercial breakthrough for our hydrogen-based energy systems for ships,” says Kristian Osnes, managing director of HAV Hydrogen.

Another key part of the project will focus on establishing a commercial operation for vessels employing hydrogen fuel. The five bulkers will go on hire through a zero-emission time charter agreement with Schulte & Burns to establish the market for the vessels and the sector.

Enova reports “The competition was fierce, and there were many good projects,” applied in this round. They received applications for a total of 45 projects, of which 13 applications were distributed among eight unique companies on the hydrogen program and 32 applications from 11 companies on the ammonia program. The goal was to reduce the barriers for actors who use hydrogen and ammonia as fuel in vessels so that the first functioning value chain within hydrogen and ammonia can be established in Norway. The next application deadline for the program’s hydrogen and ammonia in vessels is September 27.

Study Finds High Fuel Quality in Biodiesel Supply Chain

The Global Center for Maritime Decarbonization, the green-fuel think tank founded by Singapore's Maritime and Port Authority, has released a comprehensive report on the stability of biodiesel (FAME) as a marine fuel. First-generation biodiesel has been in production and use for road transport applications for decades, and it is trickling into the marine fuel market for the same reasons that it is popular on land: it is relatively cost-competitive, and it can be blended in any proportion with fossil-derived diesel fuel. GCMD set out to determine how FAME fuels are faring in maritime supply chains, with a particular eye to biodiesel's problems with degradation - and its researchers came away with positive results.

First-generation biodiesel is made by reacting natural fats - like vegetable oil or tallow - with methanol in the presence of an alkaline catalyst (lye). The products of the reaction are fatty acid methyl esters (FAME), plus a smaller quantity of glycerol. After extensive purification, the FAME is sold as a fuel. It is a common ingredient in over-the-road diesel blends in the United States and Europe.

This chemical process differs from the next-generation "renewable diesel" or "RLD" process, which runs the same natural fat feedstocks through a hydrocracker, resulting in a product identical to fossil diesel. First-generation FAME has many desirable attributes, but it also has shortcomings compared with RLD. FAME slowly degrades in the presence of water and atmospheric oxygen, both found in abundance at sea. It can also deteriorate in the tank if water is present and bacteria or mold take hold. At worst, these problems can cause sludging in fuel injectors, pumps and piping, much like "bad bunkers." FAME's natural oxidation process also creates organic acids, which can corrode piping and fuel systems.

Given these potential contamination problems, and the increasing interest in biodiesel as a marine fuel, GCMD set out to study how FAME works in real-world bunker supply chains. It followed the use of FAME fuels aboard 13 vessels bunkering in three different ports, drawing on four different suppliers. Its researchers sampled the fuel at multiple points along two of these supply chains - from the producing facility to the bunker barge - to determine whether the fuel could get contaminated or degrade before loading. (The research did not cover long-term performance aboard the vessels after loading.)

The group's findings were positive: no substantial changes were found in the substance's characteristics during five months of midstream storage, transport and blending. There were no meaningful issues with acidity, sludginess, reduced energy content or biological contamination.

"The results from our end-to-end supply chain trials indicate no significant degradation of FAME, arising from autoxidation, hydrolytic oxidation or microbial contamination under standard commercial operations conditions," the team concluded. "Given the potential for higher adoption of biofuels, the shipping industry will need to continue to build up a crucial database to develop best practices to guide the development of biofuels use."

Mitsubishi Shipbuilding Joins Methanol Sector with Order for First RoRos

Japan’s Mitsubishi Shipbuilding is joining the emerging group of shipyards capable of building ocean-going methanol-fueled vessels. While the alternative fuel is dominating new orders, with 269 orders due for delivery over the next five years according to DNV, only a few shipyards are building the vessels.

Mitsubishi Shipbuilding signed an order for Japan’s first methanol dual-fuel RoRo car carriers. The two ships will be deployed on a Japanese coastal service and designed to address the emerging trends in shipping.

Toyofuji Shipping is ordering two ships as part of a promotional project jointly sponsored by the Ministry of the Environment and the Ministry of Land, Infrastructure, Transport and Tourism. Toyofuji will own the first vessel and the second with be shared with Fukuju Ship Company. Both vessels are due for delivery by the end of 2027.

In addition to being the first dual-fuel methanol-fueled RoRos for Japan, the vessels will incorporate other design elements to improve efficiency. They will be equipped with Mitsubishi’s energy-saving technology system and energy saving propellers and high-performance rudders with reduced resistance. They will have a high-efficiency dual-fuel main engine and the shape of the bow and vertical stem is designed to reduce propulsion resistance.

The ships will be larger than the conventional coastal car carriers. The length will be increased by approximately five meters (more than 16 feet) and the tonnage will increase from 12,687 to 15,750. Loading capacity will expand by 15 percent or 300 vehicles to a total of 2,300 units. This will permit the companies to reduce CO2 emissions by more than 20 percent per unit. Overall, they expect an initial 10 percent reduction in CO2 emissions which can be further increased through the conversion to green methanol. Mitsubishi Gas Chemical Company and Kokuka Sangyo will supply the methanol bunkering from conventional vessels.

While the ships are larger, they will be able to call at conventional ports. The size increase will also address the labor shortages being experienced in the shipping industry as well as the calls for work style reforms. The increased loads will provide more schedule flexibility and rest time for crews.

Mitsubishi Shipbuilding reports it will expand on its experience with LNG to develop the new vessels. The Enoura shipyard in Shimoseki City earlier this month launched the first LNG-fueled car carrier for Toyofuji Shipping. Named Trans Harmony Green, the vessel is 49,500 tons with a capacity for 3,000 vehicles. It will be operating the company’s Asia weekly service.

Methanol-fueled car carriers are a new segment for the emerging alternative fuel. DNV reports less than seven percent of the methanol-fueled orderbook is for car carriers with only 18 vessels ordered so far for the segment. Containerships continue to make up the vast majority of the orders for methanol-fueled vessels although other segments are starting to emerge.

No comments:

Post a Comment