Seaonics Ready to Market World's First Offshore Charging Solution

[By: Seaonics]

Following successful in-port and offshore prototype testing, Norwegian lifting and handling specialist Seaonics is on track to commercialise its Ocean Charger solution for electric SOVs amid strong interest from wind farm developers.

High-voltage charging tests were conducted in port to charge the batteries on the Rem Offshore-owned diesel-electric hybrid CSOV (Construction Service Operation Vessel) REM Power (built 2023) as well offshore from a charging point (cable reel, winch and control system) mounted on a wind turbine.

"At 10 years old, the turbine is one of the smallest offshore but the prototype proved it is possible to install the Ocean Charger on an existing turbine and charge an SOV from day one, using 11 kilovolt (KV) current delivering 6 MW of charge. Apart from a handful of improvement points to fix, the concept and control system are complete and the product is available for sale as is. We're first in the market and already in talks with wind farm owners," said Bjørnar Huse, Sales Manager, Offshore Energy at Seaonics.

He adds that because power current varies between wind parks and wind turbines, the commercial version will have to be customized for each project.

Significance and benefits

The ability to charge vessels offshore in a cost-effective way is a central enabler for shipbuilders to deliver zero-emission SOVs to the offshore wind industry. "Connecting vessels to the power grid in the wind farm and charging batteries regularly is a big step towards increasing sustainable operations without using any additional energy sources. It saves the time and energy needed to return to port to charge, while the operating cost of electric SOVs versus diesel and alternative fuels is much lower, because both the energy is cheaper and you reduce engine maintenance demands. You still need diesels for back-up power, but quite a lot smaller than for a full diesel operation, with lower Capex," said Huse.

A large, 60-person SOV consumes 20 to 25 MW hours per day, so at 6 MW you can potentially charge for a full day's operation in three to four hours. "But it's better for the lifetime of the battery pack to never be completely depleted nor fully charged – between 50 and 80 percent is best. You could charge for six hours at night, say, then do ad-hoc charging during the day," Huse said.

Meanwhile, wind farm owners are moving away from the idea of locating charging points on a substation or expensive floating buoys. "The standard will most likely be to locate the charging point on a turbine. Downscaling the weight and cost also means you can have many charging points reducing the need to cruise long distances to charge. The turbines are usually owned by the developer, so they can fit as many as required. It is easier mechanically to have charging points on a substation but as these are usually owned by the grid owner, there is some doubt as to who would be responsible for their maintenance and insurance etc. This will have to be sorted out project by project," Huse added.

Standardised solution

The Ocean Charger's standardised solution is cost effective because it uses an industry-standard connector plug and power levels both for offshore charging and in port. "The prototype worked using a standard vessel and crane. The plug is an industry standard used for shore charging cruise ships as well as Hoegh Autoliners' Aurora-class hybrid-electric newbuild car carriers. Tying known technology together made it easier to get to a prototype in a relatively short time. We didn't have to invent a lot of new components unlike some competitors using a bespoke plug," Huse said.

The product can be fitted to any structure and vessel and the power integrated with the vessel switchboard and the chosen charging voltage. "The main development challenges were handling the medium/high current coming on board the vessel and navigating the relevant standards (IEC, ISO etc) for marine technical equipment. For example, there are a lot of class requirements on safety distance around the plug. Existing standards also mostly still cover shore-based equipment so we had to make an offshore version of the different components," Huse added.

The current issue

Discussions are currently underway with wind park owners regarding charging current. Wind parks usually have 66 or 132 KV requiring one or two transformers – one on the charging point and another on the vessel – to get the high voltage down to medium or low voltage. "Some have asked us to explore bringing 132 KV, which is the standard current in big power lines on land, directly onto the vessel and do all the transformation onboard. However, managing such high current would require a very bespoke handling and safety system. Feasibility depends on the cost of power integration and transformers," said Huse.

"The cost-effective compromise is to stick with 11 KV, which is what the Aurora-class vessels use but is still high considering the standard shore connection for fishing vessels and small SOVs today is typically 690 or 1,000 volts, using the same equipment for both offshore and shore charging."

Grabbing the cable

The SOV approaches the charging point and uses a crane equipped with a gripper that 'grabs' the end of the cable and pulls it onto the connection area integrated on the vessel deck. The REM Power has a fully 3D compensated crane and can connect even in rough weather, but smaller SOVs and maintenance craft that don't have a crane can use the motion-compensated gangway instead. "High accuracy isn't necessary, as the automated handling system guides the plug to the right place, eliminating any need for manual operation," said Huse.

The vessel has to be on DP during charging but with a larger footprint to reduce power consumption. The cable is slack so the vessel can move 20 metres or so back and forth without damaging anything. "The DP safety system will kick in if the vessel loses position or, if necessary, the control system will automatically release the cable in an orderly manner. The system has been designed with two levels of redundancy for emergency release," Huse said.

"It is of course possible the plug may occasionally be released in a non-orderly manner and be submerged, leading to water intrusion both in the plug and cable. That may require the whole cable to be replaced involving time and cost. No industry standard plugs have been approved or are capable of being submerged, so we had to design a watertight cover. The handling system opens the cover when the plug is on board and guides it into the charging notch, and in reverse when charging is complete."

Time for tailoring

Huse says it would take a few months to customise the configuration and get approvals for a specific wind park and vessel. "For wind farms that will be installed in two to four years' time, there is ample time to do final integration design, fabrication and installation on a new chartered SOV or retrofit an existing one. Fitting the charging points to turbines before they are installed also streamlines the operation."

Seaonics can write an offer today for the Ocean Charger in its current configuration. "We know exactly how much the vessel integration will cost, and how much the charging point on a turbine will cost. Total project cost will obviously vary depending on how many charging points it entails and customisation required to match the owner's operating parameters."

The Ocean Charger was developed by a consortium led by Ålesund-based Vard Design and sister companies Seaonics and Vard Electro, alongside partners Rem Offshore, Solstad Offshore, SINTEF Energi, SINTEF Ocean, DigiCat, Sustainable Energy, Equinor, Source Galileo Norge, Corvus Energy, Plug, Shoreline, Sustainable Energy, University of Bergen, Norce and Maritime CleanTech. "Coming up with a pioneering product at speed demonstrates what great partners with different expertise can achieve in collaboration – which is the only way to accelerate sustainability in our industry," Huse concluded.

To find out more Ocean Charger, visit us at Wind Energy Hamburg on 24-27 September (Hall B2.EG, Stand 230.23).

The products and services herein described in this press release are not endorsed by The Maritime Executive.

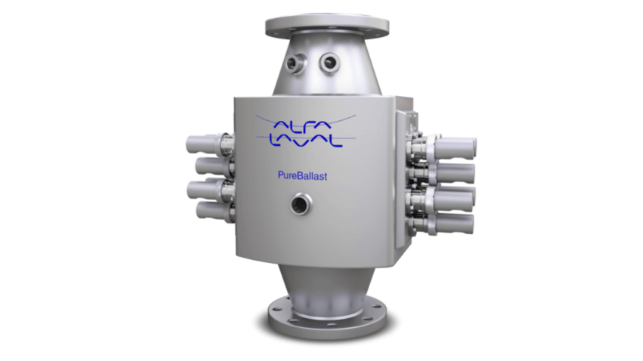

Alfa Laval Secures Order for Ballast Water Management System Replacements

[By: Alfa Laval]

Alfa Laval has received an order to replace 18 ballast water treatment systems (BWMS) onboard vessels belonging to a major European shipowner. This significant order shows the high demand for the replacement of malfunctioning systems and a growing market for Alfa Laval’s BWMS replacement offering.

Strict regulations and frequent controls are driving shipping companies to ensure their ballast water treatment systems are fully operational to avoid high costs, downtime, and potential business losses. As the majority of the world fleet is now equipped, the BWMS retrofit market is nearing saturation. Many suppliers have reduced their commitment to customers or exited the market entirely, leading to a lack of support and upgrade options as regulations evolve. This is especially challenging when the systems purchased are not functioning properly.

High demand for replacement of BWMS

Over the past two years, Alfa Laval has replaced more than 250 systems from 30 different manufacturers, and the orderbook for replacement continues to grow. “With the consolidation of the BWMS market, we see a growing need for replacing installed BWMS systems”, says Tobias Doescher, Head of Global Sales, Business Development and Marketing, Alfa Laval PureBallast. “We have been contacted by an increasing number of shipowners and ship management companies worldwide who are experiencing issues that their current supplier cannot resolve. We are happy to step in and support our customers with cost-efficient and sustainable solutions.”

Professional approach to replacement projects

Alfa Laval has experience replacing systems using electrochlorination (EC) and UV technology. The replacement projects are handled professionally by a thorough onboard assessment of the existing system by a qualified expert. This comprehensive evaluation determines necessary replacements and identifies components that can be reused, resulting in substantial cost savings for clients. The replacement process is customized for each customer, providing them peace of mind in meeting BWMS compliance.

“The success of this offering validates the way Alfa Laval has chosen to work - partnering for the entire lifecycle of ballast water management equipment rather than being a one-time supplier,” says Peter Sahlén, Head of Alfa Laval PureBallast. “While other suppliers are exiting the market, we are investing in our experts, actively following the regulations, and offering new services to facilitate compliance. We have even launched our new PureBallast 3 Ultra, developed based on years of customers´ feedback.”

The products and services herein described in this press release are not endorsed by The Maritime Executive.

No comments:

Post a Comment