World Nuclear News

Westinghouse plans ten AP1000 reactors in the USA

_34650.jpg)

Four executive orders signed by President Trump on 23 May aim to support the entire US nuclear supply chain and the ambition to quadruple the nation's nuclear energy capacity by 2050. Three of the orders are firmly focused on reforms that will boost the civil nuclear energy sector. The fourth one aims to ensure the rapid development, deployment, and use of advanced nuclear technologies to support national security objectives, including AI data centres at Department of Energy facilities.

Hosted by US Senator David McCormick, the Pennsylvania Energy Summit and Expo on 15 July highlighted the state's significant role in shaping the future of AI and energy innovation. Dan Sumner, interim CEO of Pittsburgh-headquartered Westinghouse, took part in a CEO Roundtable attended by President Trump, top Administration officials, including US Energy Secretary Chris Wright, and US Secretary of the Interior Doug Burgum.

"We've taken the call-to-action under your executive order to partner with companies across our industry to mobilise a plan to deliver ten AP1000 reactors in the US with construction to begin by 2030," Sumner said. "When we deploy a fleet aligned to your vision, we'll drive USD75 billion of economic value across the United States with USD6 billion of value here in Pennsylvania. Implementing your vision will create or sustain over 55,000 jobs across the country and over 15,000 jobs in the Commonwealth alone, and these are great jobs across manufacturing, engineering and construction."

The event showcased a USD92 billion commitment to cutting-edge AI and energy initiatives.

Utility Constellation announced that it will create 3,000 jobs per year as a result of a USD2.4 billion investment to uprate the Limerick nuclear power plant by an additional 340 MWe.

"We commend state and federal leaders for helping to make these investments possible and for recognising the unique value of reliable and safe nuclear energy to power our economy and bolster our nation's energy security," said Constellation President and CEO Joe Dominguez.

"As the nation's second largest energy producer and a global nuclear power leader, Pennsylvania is uniquely positioned to deliver the abundant, affordable energy that growing AI and advanced manufacturing sectors demand," said Senator McCormick. "We have the skilled workforce to build and operate this critical infrastructure, world-class universities driving innovation, and strategic proximity to over half the country's population."

US seeks pilot production lines for advanced reactor fuel

In response to executive orders signed by President Trump on 23 May, the Department of Energy (DOE) last month launched a pilot programme to expedite the testing of advanced nuclear reactor designs under DOE authority outside of the national laboratories, with the goal of three reactors reaching criticality by 4 July 2026. It issued a Request for Application (RFA) as it seeks "qualified US reactor companies" interested in constructing and operating the test reactors. DOE said it is currently reviewing potential applicants and anticipates selecting at least three advanced reactor designs in the coming months.

In a move to establish a domestic nuclear fuel supply chain for testing those new reactors, the DOE has now issued a Request for Application and is seeking qualified US companies to build and operate nuclear fuel production lines using the DOE authorisation process. It said it is "relying on the same authority used to expedite testing to jumpstart fuel line development and rebuild America's nuclear fuel production base".

The DOE said the new advanced nuclear fuel lines will serve research, development, and demonstration purposes. It noted that DOE authorisation will unlock the next level of private funding and provide a fast track to a Nuclear Regulatory Commission licence, "and hence, commercialisation for authorised fuel fabrication lines".

Applicants will be responsible for all costs associated with the construction, operation, and decommissioning of an advanced nuclear fuel line, as well as the procurement of all nuclear material feedstock. The selections will be based on a set of criteria, including technological readiness, established fuel fabrication plans, and financial viability.

Initial applications are due by 15 August, with subsequent applications allowed on a rolling basis.

"America has the resources and the expertise to lead the world in nuclear energy development, but we need secure domestic supply chains to fuel this rapidly growing energy source and achieve a true nuclear energy renaissance," said Energy Secretary Chris Wright. "The Trump Administration is accelerating innovation, not regulation, and leveraging partnerships with the private sector to safely fuel and test new reactor designs that will unleash more reliable and affordable energy for American consumers."

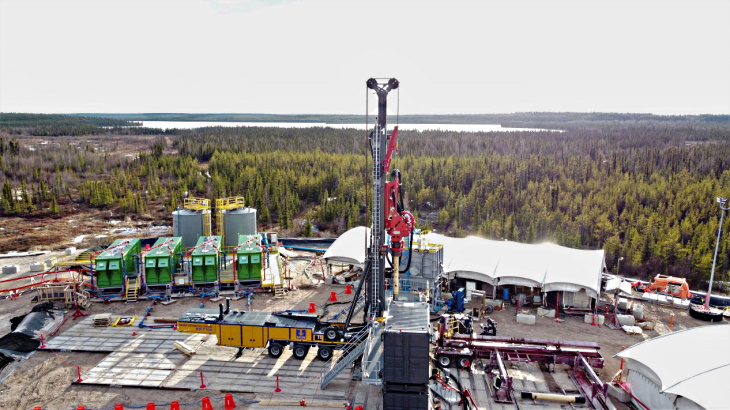

McClean Lake mine resumes production after 17-year hiatus

_12678.jpg)

McClean Lake is in the eastern part of the Athabasca Basin region in northern Saskatchewan, about 750 kilometres north of Saskatoon. The McClean Lake Joint Venture (MLJV) is 77.5% owned by Orano Canada and 22.5% by Denison. Orano Canada is the operator. Mining operations were suspended in 2008 due to declining uranium prices.

In January 2024, Orano Canada and Denison announced that production was to restart at McClean Lake using their patented Surface Access Borehole Resource Extraction (SABRE) mining method.

At that time, the companies said they intended to begin mining at the McClean North deposit in 2025, targeting production of 800,000 pounds U3O8 (308 tU, 100% basis) in 2025. Around 3 million pounds U3O8 (100% basis) has been identified for potential additional production from a combination of the McClean North and Caribou deposits from 2026 to 2030.

Orano Canada and Denison have now announced that mining of the McClean North deposit using SABRE began last month, with about 250 tonnes of high-grade ore (+10% U3O8) estimated to have been recovered from the first mining cavity. Orano Canada also said it has successfully backfilled the first cavity, advanced the SABRE rig to the planned second mining cavity, and commenced processing of the recovered ore at the McClean Lake mill.

(Image: Denison Mines)

"The first commercial production of uranium with the SABRE technique marks a new chapter, allowing us to access and explore new territories," said Orano Mining President Xavier Saint Martin Tillet. "This innovation reinforces our commitment to delivering a reliable and responsible supply of natural uranium to nuclear power producers worldwide, supporting the generation of low-carbon electricity."

Orano Canada's President and CEO Jim Corman added, "Our long-term investment in R&D within Orano and the MLJV has culminated in the safe mining, milling and packaging of ore that in the past would have been deemed economically challenging to develop ... It truly is an innovative and exciting time to be in the uranium industry."

"The successful commencement of SABRE mining at McClean North marks a significant milestone in the history of the MLJV, as the joint venture returns to active mining operations for the first time since 2008," said Denison President and CEO David Cates.

What is SABRE?

SABRE is a non-entry, surface-based mining method that uses a high-pressure water jet placed at the bottom of a drill hole to excavate a mining cavity. The cuttings from the excavation process are then air lifted to the surface, separated and stockpiled. This innovative mining method can potentially allow economic access to relatively small high-grade orebodies that are either too small or too deep to be mined economically by conventional open-pit and/or underground mining methods, the companies say.

SABRE test at McClean Lake, 2021 (Image: Orano)

SABRE also offers operational and environmental advantages compared with conventional mining techniques. It is selective and scalable, which the companies say makes it suited to changing uranium market conditions, with an expected production ramp-up of months instead of years. It is less intrusive and has a smaller surface footprint than conventional methods, with lower water usage and power consumption, and - as it is a non-entry mining method - minimises radiological exposure for mine workers.

A five-year SABRE test programme was completed at McClean Lake in 2021, excavating some 1,500 tonnes of ore.

"SABRE is unique in that the mining method can be selective and scalable, which has the potential to provide superior flexibility when compared to conventional mining methods and is thus ideally suited to ever changing uranium market conditions - with an expected production ramp up of months instead of years," according to the McClean Lake Joint Venture partners.

ČEZ and Rolls-Royce SMR sign Temelín early works agreement

Rolls-Royce SMR was selected as technology partner by ČEZ last year for the proposed installation of up to 3 GW of capacity from small modular reactors (SMRs). It also acquired a 20% stake in Rolls-Royce SMR.

The aim is to build the first SMR in the Czech Republic near the existing Temelin nuclear power plant in the mid-2030s. There are also plans being developed for their deployment at the location of current coal-fired power plants.

Tomáš Pleskač, Member of the Board of Directors and Director of the New Energy Division of ČEZ, said: "Modular reactors are a great opportunity for the Czech economy and an essential part of the ongoing energy transition. The cooperation with Rolls-Royce SMR, which we established this year, offers a unique opportunity for growth and prosperity in the field of nuclear energy, also thanks to our participation in the technology development."

Chris Cholerton, Rolls-Royce SMR CEO, said: "This agreement is an important step forward in our partnership with ČEZ, demonstrating our shared ambition to move at pace to deliver reliable, clean nuclear power in the Czech Republic. We are proud to be working alongside ČEZ to deliver a programme that will bring significant industrial and economic benefits to both our nations, while helping to meet critical energy security and decarbonisation goals."

The early works will include regulatory approvals and licensing, an environmental impact assessment and preparatory site work, as well as detailed planning and regulatory engagement.

The Rolls-Royce SMR is a 470 MWe design based on a small pressurised water reactor. It will provide consistent baseload generation for at least 60 years. 90% of the SMR - measuring about 16 metres by 4 metres - will be built in factory conditions, limiting on-site activity primarily to assembly of pre-fabricated, pre-tested, modules which significantly reduces project risk and has the potential to drastically shorten build schedules.

Earlier this week the Czech and UK prime ministers signed a memorandum of cooperation on nuclear energy which included expanding business and industrial collaboration between the two countries.

Bulgaria partners with Citi for financing of new Kozloduy units

Citi's role will be as exclusive coordinator and lead arranger of export credit, with the Bulgarian ministry saying the partnership "is a clear sign of the strong trust that international stakeholders place in Bulgaria and its energy sector".

Energy Minister Zhecho Stankov said: "The agreement with Citi is a significant step toward the successful realisation of this priority energy project for the government. The construction of Units 7 and 8, which will be the first reactors in Europe using Westinghouse’s AP1000 technology, will ensure the country’s energy independence and long-term stability."

Stephanie von Friedeburg, Global Head of Public Sector Banking at Citi, said: "Citi is proud to be at the forefront of financing low-carbon energy solutions. The Kozloduy expansion represents a landmark transaction, one of the first large-scale projects of its kind. This project is pivotal for Bulgaria's energy future, and Citi is committed to providing the financial expertise to make it a reality."

The amount of finance required for the project has not been disclosed, but in December 2023 ministers said that the aim was to achieve a price of about EUR6 billion (USD6.5 billion) for each of the units. According to the energy ministry it will be the bank's largest nuclear financing project in central and eastern Europe.

Background

Kozloduy is home to two operating VVER-1000 reactors that were connected to the grid in 1987 and 1991, respectively, and together provide around a third of Bulgaria's electricity. Both units have been through refurbishment and life-extension programmes to enable extension of operation from 30 to 60 years. Four older VVER-230 units were closed ahead of Bulgaria joining the European Union in 2007.

The USA and Bulgaria signed an intergovernmental agreement to cooperate on the development of Bulgaria's civil nuclear programme, including the plan for the new units at Kozloduy, in early 2024, and Hyundai Engineering & Construction, Westinghouse and Kozloduy NPP-New Builds signed an engineering contract in November. The aim is for unit 7 to be operational in 2035 and unit 8 in 2037.

Containment dome of Hinkley Point C unit 2 installed

_37566.JPG)

Using one of the world's largest cranes, known as Big Carl, the dome - with a diameter of almost 47 metres, height of 14 metres and weighing 245 tonnes - was lifted and then slowly lowered onto the 44-metre-high reactor building.

The dome is made up of 38 prefabricated panels which were shipped to Hinkley Point C and welded together in an onsite factory.

(Image: EDF Energy)

Work will now begin to weld an air-tight seal around the joint between the dome and the reactor building, which will then be encased with 7000 tonnes of concrete.

Construction of the first of two 1630 MWe EPR reactors at Hinkley Point C began in December 2018, with construction of unit two beginning a year later. The dome of unit 1 was put in place in December 2023.

(Image: EDF Energy)

EDF Energy noted that work on unit 2 was stopped during the Covid-19 pandemic, but teams are catching up on lost time. Their progress, it said, is helped by innovation and experience from unit 1, which means unit 2 is taking 20-30% less time to build.

Although the second dome was lifted 18 months after the first, unit 2 is further ahead, compared with the same moment for unit 1. On unit 2's civil construction, 30% fewer people achieved 40% more work than on unit 1 with prefabrication of structures now approaching 60%, EDF Energy said. In addition, more equipment has been fitted and 300 tonnes of internal steel installed, compared with just 10 tonnes at the same stage for unit 1.

(Image: EDF Energy)

"Restarting the industry has been hard, but the second of our two identical units shows the big benefits of repeating an identical design," said Stuart Crooks, CEO of Hinkley Point C. "Build and repeat is the best way to build new nuclear with time savings already at 20-30%. All our experience and innovation will benefit Sizewell C from the start."

Sizewell C will feature two EPRs and would essentially be a replica of the Hinkley Point C plant, with the aim of building it more quickly and at lower cost as a result of the experience gained from what is the first new nuclear construction project in the UK for about three decades.

A video of the dome lift can be viewed here.

Framatome to supply nuclear fuel to UAE's Barakah plant

_32604.jpg)

Under the agreement, Framatome will supply complete nuclear fuel assemblies for use at the Barakah plant. The fuel assemblies will be fabricated at Framatome's manufacturing facility in Richland, Washington, USA. Framatome will also provide engineering support services from its US headquarters in Lynchburg, Virginia.

"We are proud to provide our advanced fuel to ENEC, ensuring security of the supply and meeting the UAE's clean energy goals," said Framatome CEO Grégoire Ponchon. "The contract recognises our state-of-the-art technologies and the reliability of our workforce to provide exceptional services to our customers."

Framatome noted it has "over 40 years extensive experience fabricating fuel for Combustion Engineering design reactors like Barakah and has supplied more than 6,000 fuel assemblies of that type".

ENEC Managing Director and CEO Mohamed Al Hammadi added: "Our agreement with Framatome advances our strategy to strengthen the security and reliability of our nuclear fuel supply chain. Diversification is key to ensuring that we continue to deliver safe, clean, and reliable electricity - powering the sustainable growth of the UAE's economy. Framatome's expertise and commitment to international standards adds depth to our operations and reinforces Barakah as a global model for operational excellence in clean energy generation.

"We remain dedicated to advancing Barakah's infrastructure and capabilities, continually striving for excellence in the nuclear power industry. ENEC continues to build on its existing operations through enhanced security, competitive costs, and innovative fuel solutions."

Under a USD20 billion deal announced in December 2009, four Korean-designed APR1400 reactors have been built at the Barakah site by a consortium led by Korea Electric Power Cooperation (KEPCO). First concrete for Barakah 1 was poured in July 2012, while that for units 2-4 was poured in April 2013, September 2014 and July 2015, respectively. The units entered commercial operation between April 2021 and September 2024. The plant provides about 25% of the UAE's electricity needs.

Fuel assemblies are currently manufactured in South Korea by Kepco Nuclear Fuel - part of the prime contractor consortium led by KEPCO - and then shipped to the UAE.

"Today, ENEC continues to explore strategic opportunities that support the growth of the global civil nuclear sector, while ensuring the plant remains a cornerstone of the UAE's energy mix," the company said.

In January 2024, ENEC announced it had launched a tender for a domestic nuclear fuel assembly fabrication facility to produce fuel assemblies for the Barakah plant. It said the facility would be dedicated to the industrial fabrication of fuel assemblies from their various components.

No comments:

Post a Comment