London P&I Club Warns Industry Over Incorrect Loading of Jumbo Bags

[By: The London P&I Club\

The London P&I Club has renewed calls on ship owners, operators and charterers to address potential risks when loading Flexible Intermediate Bulk Containers (FIBCs) containing dry chemicals. The warning follows a number of incidents reported across the industry including hold fires and cargo damage in bulk carriers and general cargo ships. The issue is particularly common with vessels loading in Chinese ports.

Claims resulting from the incorrect storage and handling of FIBCs, also known as ‘jumbo bags’, can lead to significant claims, the Club notes. The Club also warns that failure to strictly comply with all relevant International Maritime Organization (IMO) regulations and guidance governing the storage and handling of jumbo bags could even prejudice P&I cover.

To help industry to understand the risks associated with incorrect handling and stowage of jumbo bags, the Club has developed a detailed video case study of a fictional bulk carrier MV Calm Sea, which can be used by vessel owners, operators and charterers, crew and port agents as a training resource for identifying risks, liabilities and best practices.

The video can be viewed or downloaded from here. A version in Chinese can be viewed or downloaded here.

Ian Barr, Chief Claims Officer at The London P&I Club said: “Given prevailing market conditions, assureds operating bulk carriers and general cargo vessels are receiving frequent requests to load jumbo bags in the same holds as breakbulk and steel cargoes or to store different bagged chemicals in the same hold. In cases of different bagged chemicals being stowed together, chemical contamination and reactions can lead to on-board vessel fires, which can result in the total loss of the entire contents of the hold and large claims. Serious problems also occur when FIBCs are stored incorrectly with breakbulk or steel cargoes, which can damage the integrity of the jumbo bags and cause significant spillage leading to delays, fines or claims.

“These cargoes may look harmless, but can be potentially very dangerous if not stowed and handled appropriately. We want to support the wider industry by raising awareness and helping operators globally to mitigate the risk of incidents and claims. We strongly urge owners, operators, charterers and Masters to use this resource and to be extra vigilant when developing stowage plans and loading FIBCs and other big bags onboard. They should alert their P&I Club so that assistance can be sought from qualified industry experts before proceeding.”

P&I cover may be prejudiced in the case of non-compliance with applicable regulations as adopted by the Flag State in relation to the storage of jumbo bags. This includes the International Maritime Organization’s (IMO) International Convention for the Safety of Life at Sea (SOLAS), the Cargo Securing Manual (CSM), the Code of Safe Practice for Cargo Stowage and Securing (CSS) Code and the International Maritime Dangerous Goods Code (IMDG) Code.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

ABS Supports Ammonia Safety Through a Comprehensive Approach

Understanding and learning ammonia’s behavior through advanced simulation is key to enhancing safety and building the confidence needed to support broader adoption, writes Gu Hai, VP, Technology (Pacific), ABS

The maritime industry is seeking to accelerate its transition to alternative fuels to meet global decarbonization targets. From LNG and methanol to ammonia and hydrogen, each offers unique advantages in the quest for decarbonization.

Among these, ammonia stands out as one of the leading candidates for achieving net-zero emissions due to its carbon-free combustion and potential scalability.

However, its adoption hinges on addressing critical safety challenges such as toxicity, flammability and corrosive properties. ABS is at the forefront of this transition, developing advanced frameworks to support ammonia’s safe integration into maritime operations while enabling compliance with evolving regulations.

Ammonia’s Challenges

Ammonia's toxicity is probably the most significant barrier to its widespread adoption, with health risks even at low concentrations. The transition to ammonia fuel will require comprehensive retraining of maritime personnel, as existing seafarer competencies do not address ammonia's unique hazards.

While ammonia handling expertise exists in specialized industries like refrigeration and fertilizer production, scaling this knowledge across global shipping presents significant challenges.

The International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW) is the training standard for alternative fuels but rules for ammonia are designed around experience with LNG as fuel. These will require revision to address ammonia's toxicity, material incompatibilities and specific emergency response protocols.

This combination of risks creates a challenge to the processes employed in shipboard safety management. The optimum multistep approach will utilize well-established techniques and potentially combine these with a new approach that draws data from the initial process and uses new agentic tools to analyze behaviors and responses in emergency situations.

Safety management baseline approaches

Ammonia safety management begins with systematic hazard identification through structured methodologies that have proven effective across industrial applications. Hazard Identification (HAZID) and Hazard and Operability study (HAZOP) workshops serve as collaborative platforms where multidisciplinary teams systematically map potential failure modes across the entire ammonia fuel system lifecycle.

These workshops employ structured brainstorming techniques, historical incident analysis, and expert knowledge to identify risks spanning from routine bunkering operations to emergency scenarios in confined engine room spaces.

The effectiveness of HAZID/HAZOP workshops is particularly evident in ammonia applications where the acute toxicity requires comprehensive risk understanding before system deployment. These sessions identify not only equipment-related hazards but also human factors risk, such as crew exposure during routine maintenance or emergency response procedures. The workshops produce detailed risk identification that serve as the foundation for subsequent quantitative analysis and mitigation strategy development.

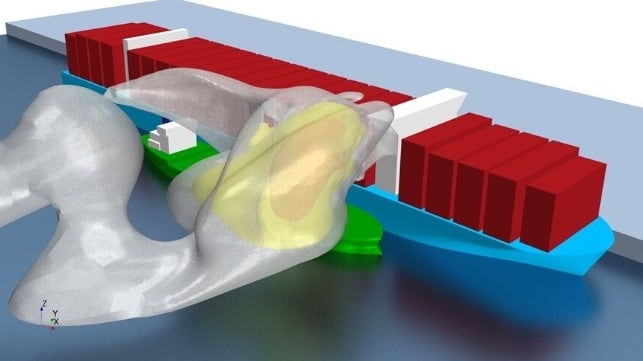

In addition, Computational Fluid Dynamics (CFD) simulations represent a critical methodology in understanding ammonia plume behavior during accidental releases, providing high-fidelity predictions that inform safety system design. These simulations model complex physical phenomena including liquid ammonia vaporization, vapor cloud formation, and dispersion patterns under different environmental conditions.

Courtesy ABS

The technology enables engineers to visualize how ammonia plumes evolve in real-world scenarios, whether during ship-to-ship bunkering operations or within confined spaces like engine rooms and fuel preparation areas.

The sophistication of CFD analysis extends to real-time environmental factors, incorporating wind patterns, temperature variations, and atmospheric stability conditions. For maritime applications, simulations are used to model dispersion from releases via the venting mast, considered to be one of the major potential risks to crew, adjacent vessels and shoreside personnel.

The critical insights generated from CFD simulations directly inform the development of emergency response plans. Live drills and exercises remain essential for validating emergency response plans, providing valuable experience to support tabletop exercises. These exercises offer realistic testing of procedures and comprehensive evaluation of physical resources and infrastructure including emergency exits, communication systems, and medical equipment.

However, live drills have limitations including high costs, resource intensity, and potential safety risks when simulating hazardous scenarios. Therefore, simulation technology plays a crucial role in overcoming the limitations of live drills while providing safe environments for testing emergency procedures under diverse conditions and can be done prior to the ship’s construction.

Agent-based emergency response plan evaluation

While existing frameworks provide a structural foundation, ammonia's unique characteristics require significant adaptations to address specific hazards and toxicity concerns. Traditional emergency response plans designed for oil spills focus primarily on environmental contamination and fire risks, whereas ammonia incidents present immediate life-threatening toxic exposure risks that demand fundamentally different response priorities.

ABS's development of advanced ‘agent-based’ probabilistic risk analysis represents a significant advancement in emergency response plans by accounting for uncertainties in both ammonia plume behavior and human factors during emergency situations. This approach integrates CFD results, human behaviors, findings from HAZID/HAZOP workshops, with realistic leakage scenarios to simulate crew responses and consequences under various identified hazards.

Agent-based modelling represents a sophisticated computational approach for simulating complex systems through the interaction of entities, known as agents, each possessing distinct behavioral characteristics, properties, and decision-making capabilities. These agents operate as independent entities within a defined environment, where they can perceive their surroundings, process information, and execute actions based on predefined rules and adaptive behaviors.

The fundamental advantage of this methodology lies in its ability to capture emergent behaviors that arise from the interactions of individual agents such as human. It enables stakeholders such as shipowners, port operators, or bunkering facility owners to simulate realistic evacuation scenarios.

This approach allows for the examination of how individual differences and local interactions may lead to large-scale patterns in evacuation flows, bottleneck formation, and overall evacuation and mitigation performance.

Agent-based modelling provides a framework to include agents such as human behavior within simulations. The human factors such as decision-making process are then integrated into the agent-based modelling through Monte Carlo simulation techniques. This approach acknowledges that human behavior during emergencies is inherently stochastic, with individuals responding differently and unpredictably to similar situations based on factors such as location, moving speed, and stress levels.

By employing Monte Carlo methods – applying computational algorithms that use repeated random sampling to model the probability of different outcomes in a process with uncertain variables - the simulation can account for the variability in human responses and generate statistical distributions of outcomes rather than deterministic predictions.

An integrated approach

The integrated approach facilitates dynamic risk assessment, where event probabilities evolve as response operations progress, incorporating real-time changes in environmental conditions, resource availability and operational constraints. This temporal dimension is crucial for emergency response planning, as the effectiveness of interventions and the risks faced by responders and evacuees change continuously throughout an incident.

The framework considers time constraints that are fundamental to emergency scenarios, where delayed decisions or actions can have chain effects on overall system performance and safety outcomes. Environmental variables such as weather conditions and hazard propagation are integrated into the models, allowing for more realistic assessments of how external factors influence both agent behavior and system-wide emergency response effectiveness.

The integration of traditional emergency response frameworks with advanced simulation such as CFD and simulation-based quantitative risk analysis helps create a more robust, system-wide and time-dependent emergency response strategy. This comprehensive approach can help to enable identification of risk hotspots, evaluation of evacuation procedures, and improved co-ordination among emergency response participants.

Gu Hai is VP, Technology (Pacific) at ABS.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.

No comments:

Post a Comment