U.S. Tariffs Derail Cambodia’s Solar Boom

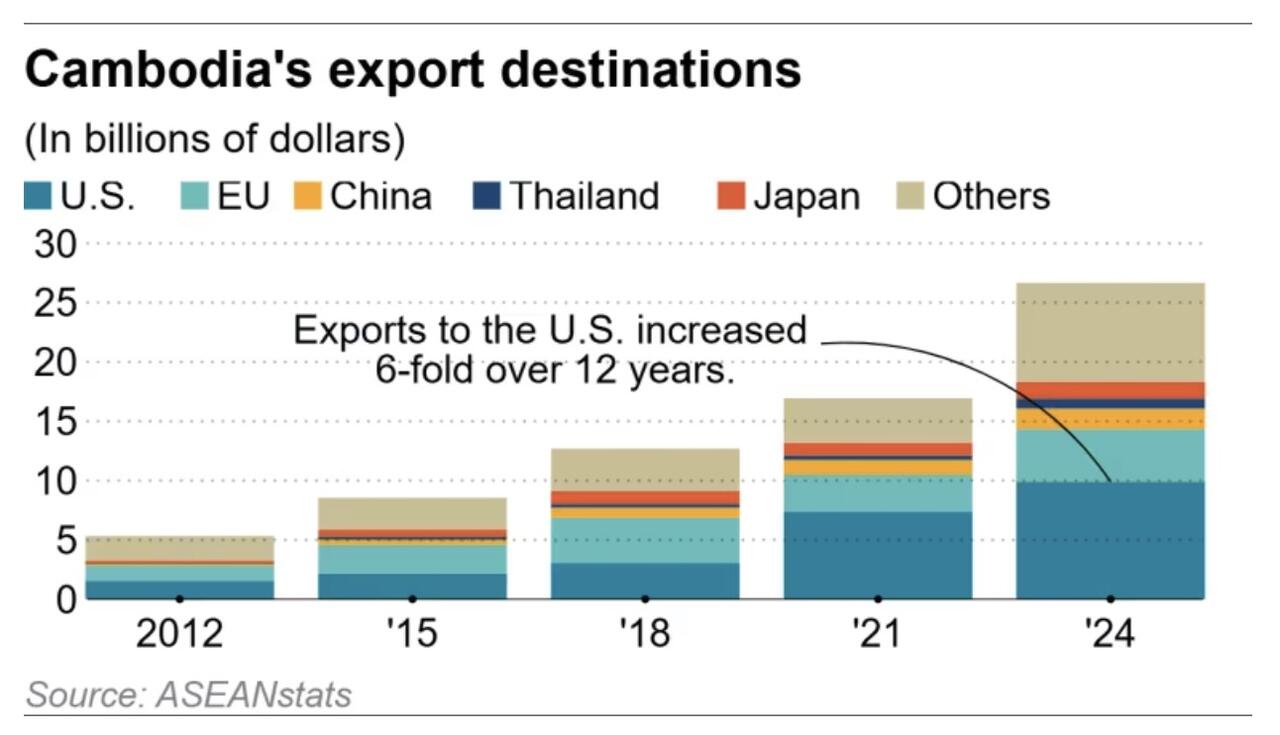

- Cambodia's solar industry experienced rapid growth, becoming a significant export sector and creating thousands of jobs, largely due to a two-year waiver on US tariffs.

- The industry's boom ended abruptly in mid-2024 when the US tariff waiver expired, leading to the imposition of extremely high duties that caused Cambodian solar exports to plummet dramatically.

- The collapse has resulted in widespread factory closures, job losses, and a shift for some remaining firms to producing alternative solar products with lower tariffs, while Cambodian producers dispute claims of transshipping Chinese-made goods.

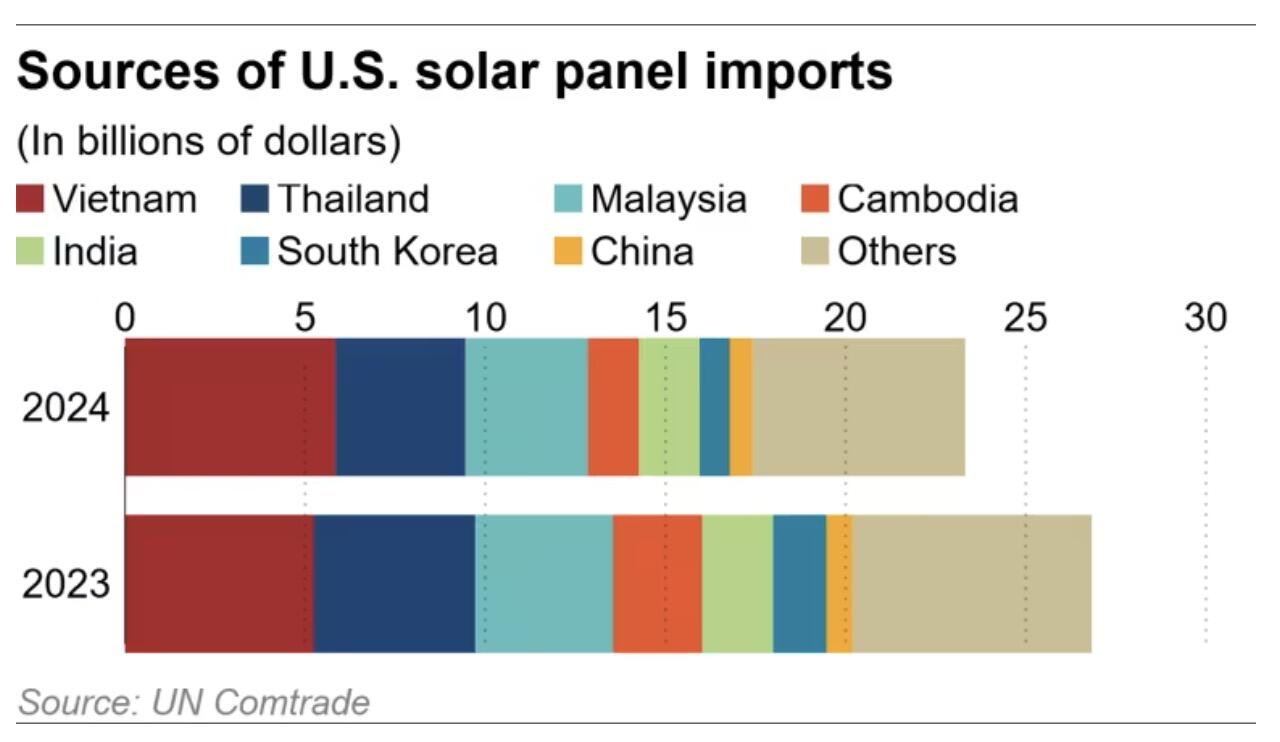

Cambodia’s solar industry rose quickly but has collapsed just as fast. At its peak in 2023, solar exports to the United States totaled $2.4 billion, making it the country’s largest manufacturing export after garments, footwear, and luggage, according to Nikkei Asia.

Around a dozen factories opened between 2018 and 2022, creating thousands of jobs and briefly turning solar into a major industry.

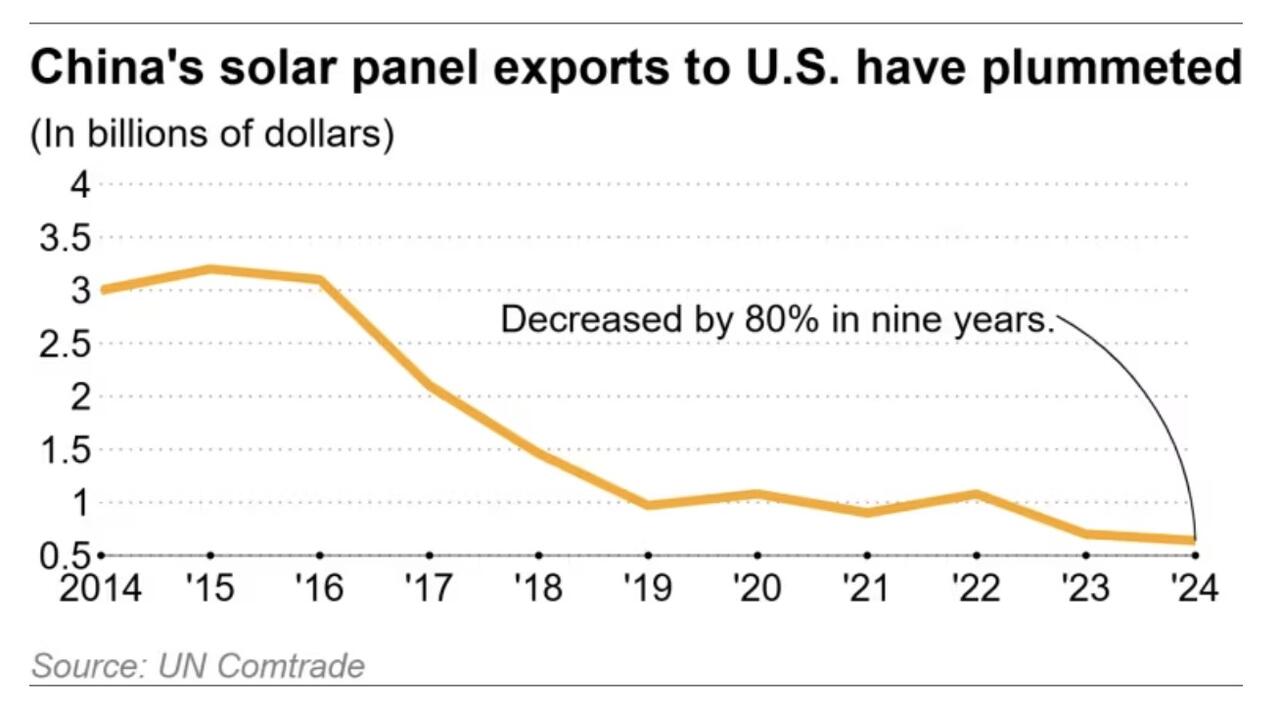

But Nikkei writes that growth ended after U.S. tariff policy shifted. The Biden administration had granted a two-year waiver on tariffs, but when it expired in mid-2024, the Trump administration imposed duties ranging from 534% to 3,403% on Cambodian solar modules. By comparison, tariffs on Malaysia, Thailand, and Vietnam were lower. The result was immediate: Cambodian solar exports fell to just $4.4 million in the first half of this year, according to customs data.

Many factories have since closed. Jintek Photovoltaic Technology, once a large exporter to U.S. buyers, shut down. Solar Long PV Tech, which had supplied BYD America, also closed after its manager left Cambodia. Hounen Solar has been reduced to only a handful of workers. “My company is temporarily closed this year, and it is because of the tariff,” said manager Sothoeuth, who had overseen 300 employees before the new duties. “We are not sure if we will restart the company again or not. It depends on the tariff.”

A few firms have tried to adapt. Venus Energy and VCOM Power System shifted production from solar modules to thin-film panels, which face only a 19% duty. These panels are more costly to make but remain viable for now. “Before, we had five companies, but now we have only two,” said VCOM’s human resources director, Thang Menghout. “If there will be a higher tariff, we cannot do it anymore.”

Cambodian producers dispute U.S. claims that they were transshipping Chinese-made products. “It is not correct, because we spent a lot of money. We had more than 1,000 workers to produce equipment, and the [Cambodian Commerce] ministry monitors us,” Menghout said. “We don’t know their politics from one country to another, [but] we don’t cheat on our products.”

For workers, the rise and fall of solar has been stark. Factories once offered higher wages than garment jobs and attracted people with promises of more advanced technology. When the factories shut, many returned to lower-paid work. “There was [later] no demand to make solar panels because the U.S. stopped ordering… Then, they reduced workers and salaries,” said former Jintek employee Men Samet, now a fruit seller in Phnom Penh.

“If solar came back, we would go back. We had good managers and high salaries.”

How Red Onion Dye Could Revolutionize Solar Panel Longevity

- Scientists have found that a dye made from red onion skin extract, combined with nanocellulose, offers a 99.9% protection rate against UV rays for solar cells.

- This bio-filter material outperforms petroleum-based alternatives currently used in solar panel manufacturing, offering a more sustainable solution to combat degradation.

- The new technology is particularly beneficial for perovskite solar cells, contributing to the development of more efficient and cost-effective solar panel designs.

Solar energy continues to break records around the world thanks to dramatically decreasing costs of deployment. A supportive policy environment and rapid advancements in technology have made solar photovoltaics one of the cheapest forms of energy out there, and as a result, solar power is on track to become the single largest renewable source on the planet by the end of the decade, even overtaking hydropower. But even greater growth will be necessary to reach net zero emissions by 2030, and in light of souring policy environments, technological innovations will be more necessary than ever to guide the hand of the market toward decarbonization.

Luckily, innovation is already ongoing. Many labs around the world are working on reshaping solar energy to be more efficient, more cost-effective, and more practical in hugely diverse ways. Scientists are looking into ways to redesign solar panels using materials that allow for greater efficiency and lower costs. Most panels are currently made using silicone, but other materials such as perovskite – which functions like a thin-film semiconductor – could offer significant advantages over current models. The problem with perovskite is that its chemistry is less stable than silicone, “which has historically presented scalability and commercialization challenges” according to Utility Drive.

For this reason, tandem solar panels – which feature a combination of silicone and perovskite – have emerged as one of the most promising solar cell manufacturing innovations. And the competition to bring them to market is heating up as a number of research teams are announcing successful testing of their respective tandem models.

Scientists are also working to find ways to improve the longevity of solar cells. While ultraviolet light is essential to the functioning of solar panels, it also breaks them down over time. The current technology to fight this degradation depends on petroleum-based products, which works against the full life-cycle sustainability of solar energy. Plus, extending the life of solar panels will help to mitigate the increasingly critical issue of solar panel waste.

A team of scientists in Finland may have just discovered a high-performance eco-friendly material to replace those petroleum-based protections – and it comes from an extremely unlikely source. According to a report from Live Science, “red onion dye could be the missing ingredient required to bolster ultraviolet (UV) protection for solar cells.” In fact, testing has shown that “combining nanocellulose with a dye made from red onion skin extract” has resulted in a stunning 99.9% protection rate from UV rays.

Nanocellulose is another biologically-based material used as a film for solar panel protection. “In the quest to drive the adoption of film made from more sustainable, biologically-based materials, nanocellulose has emerged as a frontrunner,” reports Live Science. “Nanocellulose is derived from plant-based materials and is produced by breaking down cellulose into nanoscale fibers,” the article goes on to explain.

According to the scientists’ study, which was just published in the scientific journal ACS Applied Optical Materials, “UV−vis-NIR spectroscopy demonstrated that CNF-ROE blocked 99.9% of radiation below 400 nm, showcasing its superior UV-blocking capability compared to the other materials tested here.” One of the materials that this bio-filter outperformed is a commercial PET-based filter currently in use by solar panel manufacturers.

Adding to the excitement, the team reports that the technology could be particularly helpful in the context of perovskite solar cells, indicating a win-win for the future of more efficient and cost-effective solar panel design.

Such advances in solar panel design could be critical to continuing the clean energy transition’s forward momentum in a time of unprecedented uncertainty and political backpedalling. In order for solar power to continue its boom, increased adoption has to make economic sense – with or without policy supports. And that might not be too far-fetched. In fact, the Science Friday podcast posits that solar power’s continued rise could balance out other clean energy cuts, in a win for the clean energy sector and for the planet.

By Haley Zaremba for Oilprice.com

China Tackles Price Wars as Bloated Solar Sector Amasses Huge Losses

China has launched in earnest the drive to curb excess capacity in the solar manufacturing sector, which has doomed many companies to price wars and deepening losses.

The combined losses of six of China’s biggest solar panel and cell manufacturers doubled in the first half of 2025, to $2.8 billion (20.2 billion Chinese yuan), from the same period last year, the Financial Times reports, citing data from local financial information provider Wind.

All top Chinese solar equipment producers had already booked losses for the first quarter of 2025, blaming the continued losses on low product prices and the trade and tariff turbulence under U.S. President Donald Trump.

The Chinese solar wafers, panels, switchers, and other equipment producers have been struggling on the domestic market amid overcapacity that China’s authorities moved to address only in late 2024.

Earlier in 2024, the China Photovoltaic Industry Association said that China urgently needs consolidation in the solar manufacturing industry as overcapacity and price wars are leading local companies to a race to the bottom.

This summer, China’s authorities are stepping up efforts to address the overcapacity in China’s clean technology industries, which undermines the profitability of solar equipment manufacturers.

Chinese authorities have realized that cutthroat competition, overcapacity, and low-quality manufacturing are hurting enterprises. Following months of introducing several measures to try to curb excess cleantech manufacturing capacity, China has now vowed to become more serious in addressing the problem.

Chinese authorities and media have intensified in recent weeks the message that the “disorderly price competition” and overcapacity need to be addressed.

In July, executives from 14 leading Chinese solar firms were summoned by China’s Ministry of Industry and Information Technology (MIIT), where Industry Minister Li Lecheng called on the manufacturers to end price wars, phase out outdated and severely underutilized capacity, and shift toward innovation and value-based competition.

The minister “stressed that the next phase will prioritize product quality, stronger regulations, and sustainable development with ongoing government support,” solar panel manufacturer Huasun said, commenting on the meeting.

By Michael Kern for Oilprice.com

No comments:

Post a Comment