World Nuclear News

External power restored to Zaporizhzhia nuclear plant after 30 days

International Atomic Energy Agency Director General Rafael Mariano Grossi called the repair of the Dniprovska 750 kV power line, which has been down since 23 September, a "crucial step for nuclear safety and security".

According to the agency, it "continues to coordinate with both sides on further repairs" to the back-up Ferosplavna 330 kV line, which was disconnected in May.

The repair work began on Saturday after what Grossi said had been "weeks of complex negotiations" leading to Russia and Ukraine agreeing "to an IAEA proposal to establish temporary ceasefire zones around two specific locations on opposite sides of the frontline, to enable their respective expert teams to conduct repairs on two power lines that were recently damaged during the military conflict".

Before the war, there were 10 different external power lines to the plant, but by May this year that number had fallen to one, with one back-up line. Both sides accuse the other of causing the damage to the power lines to the plant, which is on the frontline of Russian and Ukrainian forces.

The six-unit Zaporizhzhia nuclear power plant has been under Russian military control since early March 2022. All its units are shut down. It is the tenth time that the plant has lost external power, although on previous occasions it was for a matter of hours rather than the current case of weeks.

Without external power supply it relies on a fleet of emergency diesel generators to provide essential safety functions, including powering cooling pumps. The IAEA says that its monitoring has confirmed that radiation levels remain within normal levels.

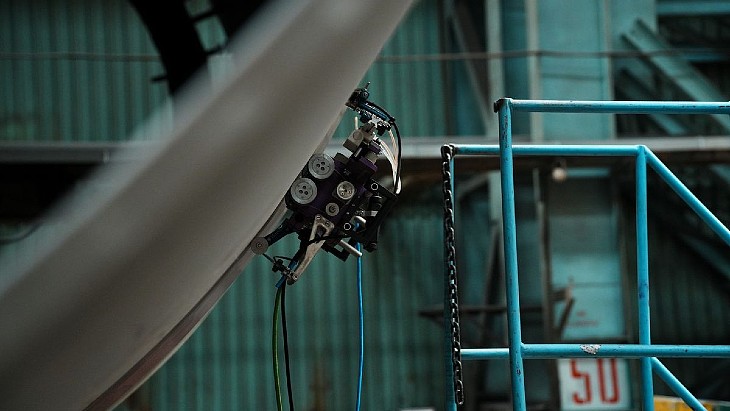

Spider robot speeds up weld inspection times, Rosatom says

The robotic system has been launched by Atommash, Rosatom’s mechanical engineering division, to inspect welded joints in nuclear power plant reactors and steam generators.

Ultrasonic testing is used to detect any defects that might not be caught in a visual inspection and is widely used in the nuclear and other industries.

There is also a fast-growing range of robotic solutions being used in the construction, inspection and decommissioning of nuclear energy facilities. The newly launched spider robot can navigate a range of surfaces at different angles and can be manoeuvered to hard-to-reach areas.

Oleg Shubin, Quality Director at Atommash, said: "By implementing robotics, we not only improve production efficiency but also create the work environment of the future. To achieve a quantum leap in development, we must create products that will shape the future. Digitalisation is becoming the key tool for this. A modern plant is a place for innovation and the implementation of bold projects. The spider robot is a clear example of how technology serves the safety of the nuclear energy industry."

Atommash said it is part of a series of developments designed to create a "digital" plant, and says that in total 30 robotic automation projects are in the process of being implemented which it says will potentially save hundreds of thousands of person-hours a year in "transportation, welding, cleaning and inspection processes".

South African government approves draft 2025 IRP

_36717.jpg)

Announcing the Integrated Resource Plan (IRP) 2025 at a livestreamed event on 19 October, Minister of Electricity and Energy Kgosientsho Ramokgopa said South Africa's electricity crisis had stunted development and economic growth. But now the country has "turned the corner" on load-shedding, it can address the future with an IRP that aims to address electricity supply issues, promote economic growth, and create jobs, targeting a 3% growth in the South African economy by 2030.

The final version presented to the South African Cabinet represents a ZAR2.23 trillion (USD128 billion) investment.

The IRP is not a "wish list", the minister said. "This is not a guide. This is a policy of government. This is what is going to drive the electricity agenda in the country for the period that we are going to define and we're going to ensure that we achieve a number of elements going forward."

"There is no economy that grows if the lights are off. There are no industries that will decide to locate in South Africa if we can't guarantee them available electricity that is of good quality and that is affordable."

South Africa's current energy mix, as outlined by the minister, is heavily dependent on fossil fuels: 58% coal, 10% rooftop solar photovoltaics (PV), 10% grid-connected solar PV, 8% wind, 4.5% diesel, 4% pumped storage, 3% nuclear and the remaining 3% from "small" contributors such as biomass and hydro.

The IRP calls for the addition of more than 105 GW of new generation capacity by 2039, including expansion of solar PV, wind and nuclear. This, Ramokgopa said, would be akin to rebuilding state-owned utility Eskom "two and a half times" by 2039: "The biggest investment programme of the post-apartheid era is what we are presenting to the country today and to ensure that we are able to achieve energy security."

Fossil fuels do not disappear: the IRP calls for the introduction of 6000 MWe of gas-powered generation by 2030 which it says is critical for energy security and stability, as well as a vision for a clean coal technology demonstration plant by 2030.

The IRP calls for 5200 MW of new nuclear generation by 2039, but this could potentially be expanded further. "We think that there's an opportunity for another 4800 MW of nuclear, but that will be supported through our nuclear industrialisation plan so that we are able to participate in the entire value chain," Ramokgopa said.

The two biggest risks to not achieving the aims of the IRP are a limited skills pipeline - in part due to the decision to place on hold the country's pebble bed reactor development programme which meant skills had been "haemorrhaged" - and a "decimated" construction industry, the minister said. "So it's important that the industrialisation plan also answers the question 'where are the skills going to come from'."

Realism

Bismark Tyobeka, principal and vice-chancellor of South Africa's North-West University, former CEO of the National Nuclear Regulator and current chair of the Ministerial Expert Panel on Nuclear, described the IRP as "bold" and "progressive" for recognising the urgency needed to respond to climate change and scaling back reliance on fossil fuels, as well as repositioning South Africa as envisioning reviving the nuclear fuel-cycle value chain as the country repositions itself as Africa's "foremost nuclear nation".

The nuclear project timescales in the plan are realistic, he said.

“This would mark a return to the fundamentals of domestic nuclear capability by enriching our own fuel for peaceful electricity generation and for non-power applications. It would support not only power reactors but also non-power reactors such as the planned new multi-purpose reactor at Pelindaba, which will replace the ageing SAFARI-1 facility. This new reactor will strengthen South Africa’s position in producing radioisotopes and other nuclear-based innovations with applications in agriculture, mining, and manufacturing.

"It is indeed an ambitious plan, but I welcome the minister's pragmatic approach and its proposed implementation in manageable stages. Achieving the first 5200 megawatts by 2039, with the initial 1200 megawatts delivered by 2036, is a realistic target. Ten years is not an excessive timeframe if one considers that, for nuclear newcomer countries, the International Atomic Energy Agency (IAEA) milestones framework typically anticipates a 12- to 15-year process from planning to first electricity generation, including at least seven years of construction."

He added: "Given the preparatory work already done by the South African nuclear sector - including Necsa, the Department of Electricity and Energy, and the National Nuclear Regulator, which has been modernising its regulatory framework - the timeline is achievable. We also have the National Radioactive Waste Disposal Institute fully operational and expanding its capacity, and Eskom itself has shown encouraging signs of financial recovery, recently reporting a profit exceeding R100 billion.

"The time is right, and the key players are ready. From our side, as members of the Ministerial Advisory Panel, we must ensure that implementation happens as swiftly as possible. Our advice on the IRP should focus on achieving the shortest feasible delivery timelines while maintaining the necessary pace and scale of government action. Procrastination is the thief of time, and we cannot afford to delay further."

State-owned utility Eskom said it welcomed the launch of IRP 2025, which it said provides a clear investment framework for the supply of electricity needed to accelerate economic growth and inclusion in a context where overall unemployment stands at 30% and youth unemployment exceeds 50%. It will now conduct a "thorough review" of the IRP and subsequently publish a response along with an updated strategic plan.

The Integrated Resource Plan is described by the South African government as a "living plan" that is expected to be continuously revised and updated as necessitated by changing circumstances. It was first promulgated in March 2011, and last reviewed in 2023.

Nuclear propulsion could be viable option for shipping industry, says DNV

Shifting environmental requirements are "reigniting interest" in nuclear propulsion as a long-term solution for maritime decarbonisation, according to Norwegian classification society DNV. However, it says significant challenges remain to be met before nuclear propulsion can become a viable solution.

_43508.jpg)

The shipping industry consumes some 350 million tonnes of fossil fuel annually and accounts for about 3% of total worldwide carbon emissions. In July 2023, the shipping industry, via the International Maritime Organization (IMO), approved new targets for greenhouse gas emission reductions, aiming to reach net-zero emissions by, or around, 2050.

"Nuclear propulsion, once regarded as a distant prospect, is now under active consideration as a real option for the commercial maritime fleet," DNV Senior Principal Researcher Ole Christen Reistad says in the foreword a new white paper. "Shipyards and shipowners are exploring its potential and weighing the promise of virtually emission-free power against the complexity of introducing such a transformative technology into commercial fleets."

DNV's white paper - titled Maritime nuclear propulsion: Technologies, commercial viability, and regulatory challenges for nuclear-powered vessels - highlights how maritime nuclear technologies differ from land-based reactors, and emphasises the need to address technological, regulatory, and commercial factors in the effort to understand the potential role of nuclear propulsion. The paper addresses the main elements of the future maritime fuel cycle – including fuel management, waste handling, vessel construction and operation, and oversight of nuclear supply chains – and presents the reactor technologies most likely to be adopted by shipowners. Advances in automation, digitalisation, and modular design are identified as critical enablers of safety, security, and non-proliferation of future nuclear fuels and reactors, thereby paving the way for public acceptance.

"All maritime nuclear technologies will differ from land-based equivalents due to some key characteristics, such as mobility, exposure to harsh sea conditions, and operational profile," the paper notes. "Further, maritime installations will vary significantly depending on their purpose - propulsion (nuclear-powered ships) or power generation (floating nuclear power plants)."

DNV says a cost-effective and proven nuclear fuel cycle, tailored for maritime use, must be developed by the industry. This includes establishing clearly defined roles and responsibilities across the supply chain, from fuel production and reactor integration to loading, exchange, and disposal. "Crucially, storage and disposal of spent nuclear fuel are fundamental to the functionality and credibility of the supply chain. Reactor design and fuel type will directly influence these requirements, and these factors must be addressed before any operating licence is granted."

As part of this, it says provisions for the whole maritime fuel cycle - including long-term waste management - are essential, not only for regulatory compliance but also for advancing public acceptance.

The development of a commercial maritime nuclear industry also needs to be supported by a "predictable and internationally accepted" regulatory framework, DNV says. Organisations such as the IMO and the International Atomic Energy Agency must lead efforts to establish standards for fuel management, ship construction, and operational protocols. "Classification societies will play a critical role in enabling global adoption, helping to overcome the fragmented nature of the land-based nuclear industry and fostering a standardised maritime approach," it says.

DNV noted: "The regulatory landscape for nuclear shipping will likely exceed what the maritime industry is accustomed to, opening the door to multiple future system configurations. By identifying key actors, their mandates, and the need for coordination, regulatory roadmaps outlined in this white paper offer essential guidance. As roles multiply, clarifying interfaces becomes increasingly important - something these roadmaps help address by mapping key interdependencies."

The success of future maritime nuclear installations will also depend on the development of compelling business models, according to DNV. It says these must reflect the commercial realities of shipping and provide a clear understanding of total cost of ownership, especially across the entire fuel cycle. "Cost-competitiveness could be significantly enhanced through modular and standardised approaches, which streamline construction, simplify maintenance, provide independent assurance, and facilitate regulatory approval across jurisdictions."

DNV case studies presented in the paper show that nuclear can out-perform other technologies under both low and high fuel price scenarios. A reactor cost below USD18,000/kW could be competitive if full decarbonisation is achieved by 2050, it suggests, while costs below USD8,000/kW could be viable even without full decarbonisation.

"Realising the potential of nuclear propulsion in maritime requires more than technological readiness," DNV concludes. "It demands coordinated global action, involving a wide range of actors across the maritime industry, regulators, and society in general. With strategic investment and international collaboration, nuclear energy could become a cornerstone of the maritime energy transition, delivering safe, efficient, and zero-emission propulsion for the global fleet."

Approval of container ship design

The release of the white paper came as DNV awarded South Korea's HD Korea Shipbuilding & Offshore Engineering (HD KSOE) - a subsidiary of HD Hyundai - Approval in Principle for a new 15,000 TEU-class container vessel design powered by small modular reactor (SMR) technology. The vessel concept incorporates a supercritical CO2-based power generation system, which can provide higher thermal efficiency and a reduced equipment footprint compared to conventional steam-based systems.

DNV Technical Director Geir Dugstad (left) and HD KSOE Senior Vice President Sungkon Han (Image: DNV)

An Approval in Principle (AiP) is an independent assessment of a concept within a defined framework of requirements. It confirms the feasibility of the design and verifies that no significant technical barriers exist to its implementation.

During the development of the ship design concept, the DNV team worked closely with HD KSOE to assess the vessel's overall safety and the design of the advanced power generation system. This review included the vessel's main functions, power supply and overall approach to safety. In May 2025, HD KSOE and DNV also conducted a HAZID (Hazard Identification) workshop at DNV's headquarters in Oslo to identify potential risks and accident scenarios for nuclear-powered vessels and to guide improvements in the design.

"This SMR-powered container vessel concept represents a key milestone in our efforts to explore alternative fuels for decarbonising shipping," said HD KSOE Chief Technology Officer Chang Kwangpil. "The design focuses intensely on the safety of the vessel and advancing the propulsion system in the application of SMR technology. In addition, we have developed a novel shielding and containment system, which is designed to maintain reactor safety and vessel survivability even in the event of collisions, groundings, or sinking accidents. We will continue to collaborate with global partners to advance marine nuclear technologies."

"With little recent experience in utilising nuclear power for cargo vessels, this AiP represents an important first step in building the technical verification process for nuclear-powered vessels," said Geir Dugstad, Technical Director at DNV. "We are very pleased to award KSOE this new AiP, which is the well-deserved result of an intensive and productive cooperation, which we look forward to continuing as this exciting technology continues to develop."

Previously, HD KSOE obtained Approval in Principle from the American Bureau of Shipping for a 15,000 TEU-class container ship design model applying SMR technology.

Laser enrichment technology moves to next level

Independent third-party validation has judged that Global Laser Enrichment (GLE) has achieved Technology Readiness Level 6, following the completion of its large-scale uranium enrichment demonstration programme using SILEX laser enrichment technology.

_31168.jpg)

GLE, the exclusive licensee of the SILEX laser enrichment technology invented by Australian company Silex Sytems Ltd, began large-scale demonstration testing of the uranium enrichment process at its Test Loop facility in Wilmington, North Carolina, in May. By mid-September, it had collected extensive performance data which the company said gave it the confidence that the process can be commercially deployed. This has now been validated independently by a leading Fortune 1000 technology provider in the national defence and global infrastructure markets, the companies said.

The nine-point Technology Readiness Level (TRL) scale was pioneered by NASA in the 1980s as a measurement system to assess the maturity level of a particular technology, from TRL-1 (basic principles observed) through to TRL-9 (total system used successfully in project operations).

GLE has now reached TRL-6, as defined by the US Department of Energy's DOE Technology Readiness Assessment Guide (G 413.3-4A), which means the technology has now been demonstrated in a relevant environment at the prototype or pilot scale, and is ready to move forward to full-scale systems.

"In plain language, this independent validation means that GLE has demonstrated large-scale, integrated system performance under relevant operational conditions and that our schedule for initial commercial deployment is achievable," GLE CEO Stephen Long said. "We are proud to be the first company to meet this significant milestone for a third-generation enrichment technology.

"We now turn our attention to full-scale detailed design and disciplined deployment of our Paducah Laser Enrichment Facility (PLEF) in Paducah, Kentucky. The PLEF would be built from an entirely-US supply chain, maintaining control of this vital new technology in the US and is expected to create first-rate advanced manufacturing jobs not just in Paducah, but around the country."

Silex CEO and Managing Director Michael Goldsworthy said achieving TRL-6 was a "major de-risking milestone" in the commercialisation of SILEX technology. "We are immensely proud of GLE, the only company in the world to have demonstrated large-scale, third generation laser-based enrichment technology at TRL-6 status," he said. "We thank the GLE and Silex teams, and our joint venture partner Cameco, for the significant efforts that have gone into achieving this seminal milestone. At a personal level, I am incredibly proud of what the Silex and GLE teams have achieved and look forward to continuing our efforts toward commercial deployment."

GLE said its commercial deployment is backed by more than USD550 million in privately funded engineering, design, manufacturing, and licensing activities across North Carolina and Kentucky and is one of six companies awarded an Indefinite Delivery, Indefinite Quantity contract under the Department of Energy's Low-Enriched Uranium programme.

The company completed its full licence application to the US Nuclear Regulatory Commission for the Paducah Laser Enrichment Facility in July. If approved, the facility would represent a multi-billion-dollar investment opportunity in the state, creating more than 300 permanent jobs when the plant is in operation. If commissioned, the facility is expected to re-enrich more than 200,000 tonnes of high-assay depleted uranium tails acquired from the US Department of Energy and produce up to 6 million separative work units of LEU annually, delivering a domestic, single-site solution for uranium, conversion, and enrichment.

Newcleo, Nextchem joint venture launched

_99869.jpg)

Nextchem - a subsidiary of Italy's Maire SpA - and Newcleo signed a binding agreement in June that would see Nextchem take 60% of the joint venture, tentatively named NextCleo, with Newcleo having 40%. Nextchem will be granted an initial stake of 1.25% of Newcleo shares, increasing to around 5% pending specific milestones.

"Following the approval of the competent authorities, the finalisation of the agreements announced in June has been reached," Nextchem has now announced. "The completion of the additional corporate activities required for the mutual transfer of minority shareholdings in NEXT-N (40% Newcleo) and Newcleo (up to 5% Nextchem) will take place, as previously communicated, by the end of 2025."

Newcleo will develop the nuclear reactor for its LFR-AS-200 technology, while Nextchem will leverage its own know-how to enable the joint venture company to deliver the extended basic design, procure the critical proprietary equipment relevant to the conventional island and balance of plant of the nuclear power plant, and provide project management/integration services to Newcleo. The joint venture - now renamed NEXT-N - will also provide services to other small and advanced modular reactor technology providers.

Newcleo has awarded a EUR70 million (USD81 million) engineering services contract to NEXT-N to develop the basic design of the conventional island and balance of plant of a first-of-a-kind nuclear power plant based on Newcleo’s LFR-AS-200 reactor design.

"NEXT-N will facilitate and accelerate the development and commercialisation of the LFR-AS-200 by Newcleo, as well as other technologies," Nextchem noted. "In particular, within the framework of the E-factory for chemistry model, detailed studies on the integration of the small modular reactor with hydrogen and ammonia technologies have been developed, to leverage a safe, reliable and competitive energy supply for the production of carbon neutral chemicals."

"We are very happy to launch our company NEXT-N, dedicated to creating new IP for the conventional island," said Nextchem Managing Director Fabio Fritelli. "With this contract we start the engineering activities for the first ever new-generation nuclear power plant based on Newcleo's innovative advanced modular reactor. We have already started to collaborate also with other nuclear technology providers to serve the nuclear industry. With NEXT-N we started a new path to industrialise carbon-neutral chemistry models based on safe, reliable and competitive energy supply. We will contribute to transform the Italian supply chain in a new energy transition paradigm and to foster new competences in Italy and Europe."

Paris-headquartered Newcleo's delivery roadmap sees the first non-nuclear precursor prototype of its reactor being ready by 2026 in Italy and the first reactor operational in France by the end of 2031, while the final investment decision for the first commercial power plant is expected around 2029.

At the same time, Newcleo will directly invest in a mixed uranium/plutonium oxide (MOX) plant to fuel its reactors. It has initiated site acquisition and public consultation processes in France for the MOX fuel pilot assembly line in Nogent-sure-Seine. It has also established a joint venture with Javys for up to four LFR-AS-200 reactors at the Bohunice nuclear power plant site in Slovakia.

No comments:

Post a Comment