Feds must force pensions to fund Canadian mining, Lassonde, Giustra say

Colin McClelland | February 25, 2024 |

Highland Valley Copper Operations in British Columbia sports the flag.

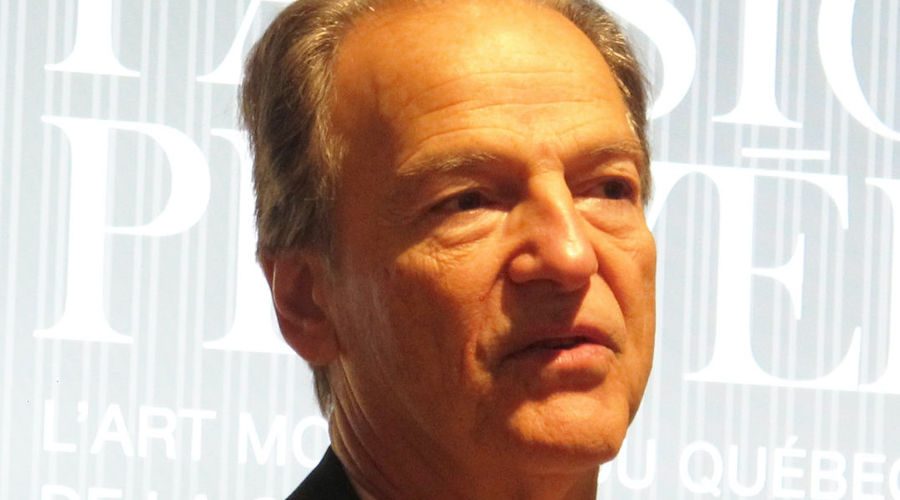

Ottawa has to pressure pension funds to invest billions in Canadian mining, a radical change from their almost non-existent stakes, if the industry is ever going to produce enough metals to fight climate change, veteran entrepreneurs Pierre Lassonde and Frank Giustra say.

Canada’s eight largest pension funds hold some C$2.1 trillion in assets but only a quarter was even invested in the country last year, according to research by Montreal-based fund manager Letko Brosseau. The so-called Maple Eight devoted just 3% to domestic equities, the lowest of a group of six countries including the United States, the United Kingdom and Japan, data show.

“They’ve taken the vast majority of this money – 75% of it – and invested it outside Canada to create jobs outside of Canada to the detriment of Canadians,” Lassonde, a founder of Franco-Nevada (TSX: FNV; NYSE: FNV) and a former president of Newmont (NYSE: NEM; TSX: NGT), said in a phone interview this month. “Essentially, the mining industry has been ignored.”

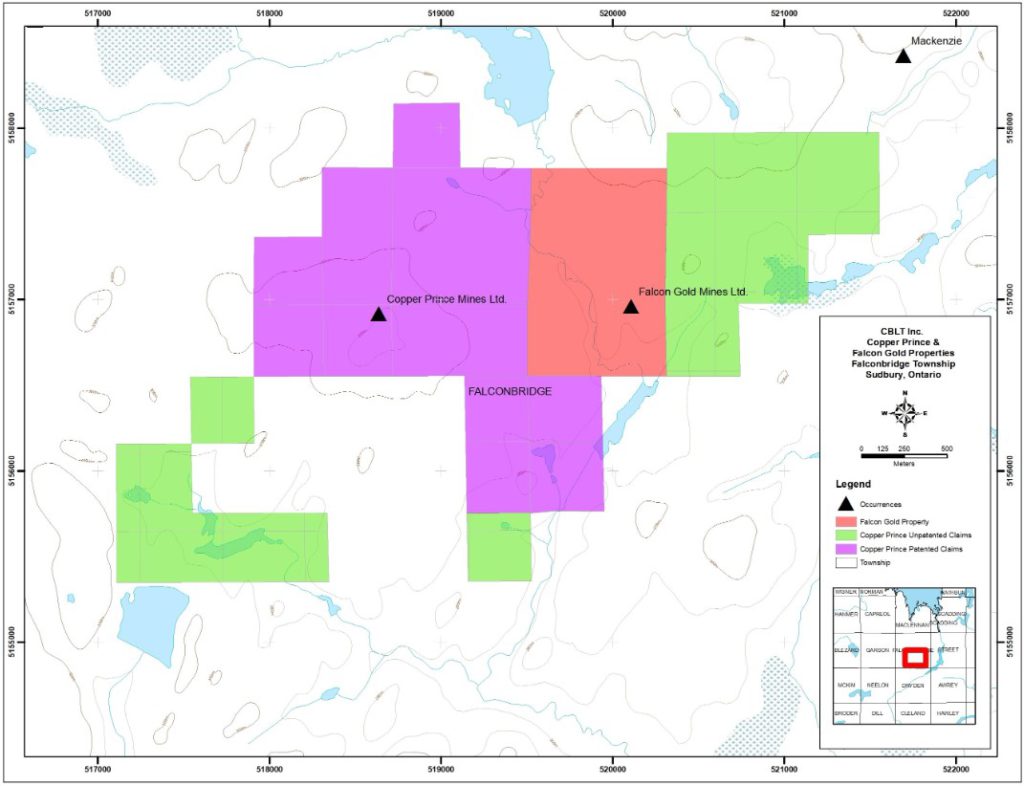

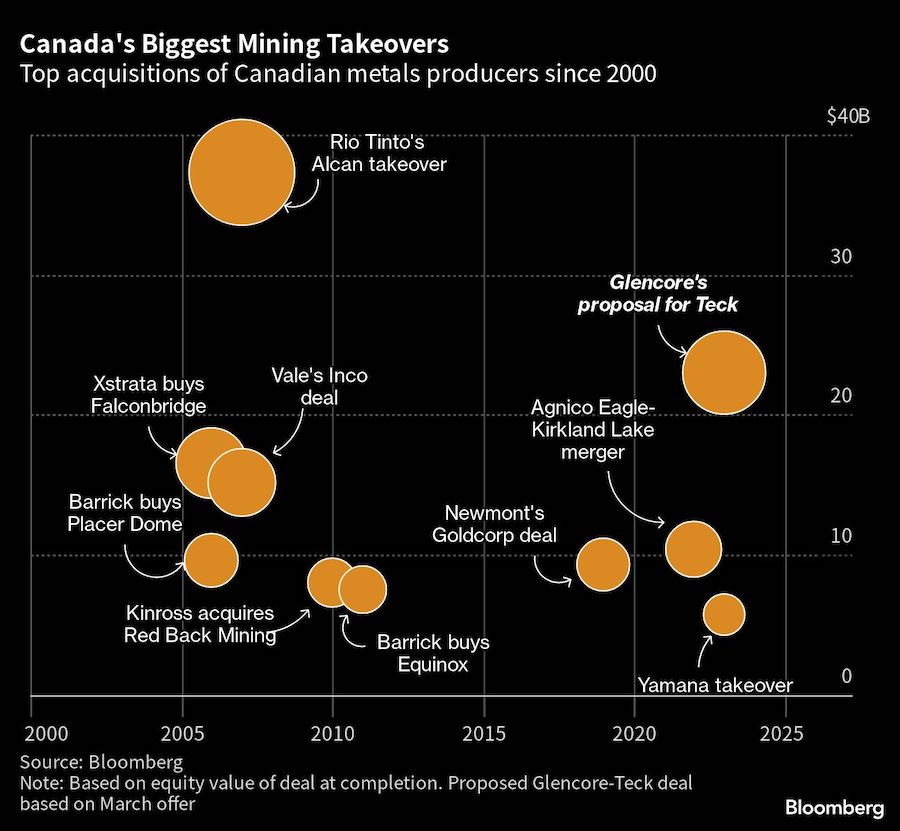

Pension funds are not investing in large Canadian mining companies, which may in turn invest in juniors, in part because few domestic options remain. Switzerland-based Glencore’s (LSE: GLEN) acquisition of most of Teck Resources’ (TSX: TECK.A/TECK.B; NYSE: TECK) coking coal assets in November for about C$9 billion is the latest large deal scooping up Canadian assets.

Xstrata, now part of Glencore, bought nickel giant Falconbridge for C$39 billion in 2006, the same year Brazil’s Vale (NYSE: VALE) purchased the country’s other main nickel producer, Inco, for C$19 billion. Australia’s Rio Tinto (NYSE: RIO; LSE: RIO; ASX: RIO) followed a year later in acquiring aluminum producer Alcan for C$38 billion. Lassonde and Giustra say pension fund investing might have helped them stay.

“We’re talking about very large companies, mining giants that we lost to foreigners,” said Giustra, who founded Lions Gate Entertainment (Fahrenheit 9/11, The Hunger Games) and helped start Wheaton Precious Metals (TSX: WPM, NYSE: WPM; LSE: WPM) and Endeavour Mining (TSX: EDV; LSE: EDV).

“These aren’t risky companies. This was the backbone of our mining industry in this country.”

Rules eroded

Indeed, Canadian pensions were required to invest 90% of their assets domestically in 1990, but federal governments gradually reduced the limit before removing it entirely in 2005. Total domestic exposure as a percentage of assets ranges from 55% held by the Healthcare of Ontario Pension Plan to 13% run by Public Sector Pension Investments (PSP). The average of other pension funds around the world is 52%, according to Letko Brosseau.

Pensions are the largest repository of wealth in many countries and globally hold nearly $50 trillion. Reaching net zero emissions by 2050 will require annual clean energy investment worldwide to more than triple by 2030 to around $4 trillion, according to the International Energy Agency. Just mining enough battery metals over the next three years will cost as much as $450 billion, the agency said. In 2022, Ottawa budgeted nearly C$4 billion in spending on critical minerals by 2030 but it’s not clear how pension funds are being engaged to support projects.

“The government of Canada continues to engage with critical minerals stakeholders, including pension plans and other institutional, arms-length investors,” Michael MacDonald, a spokesman for the federal Natural Resources Ministry, said in an emailed reply to questions.

It was MacDonald’s only reference to pension funds in what was otherwise a page-long list of government programs stemming from its critical minerals strategy. He suggested the Canada Development Investment Corp. (CDEV), a federal Crown corporation that advises the government on financial matters, might explain how mining companies could seek funding from the C$15 billion Canada Growth Fund. CDEV didn’t reply in time for this story.

Pensions mum

Pension funds themselves were even more reticent to discuss the issue. Only the Caisse de dépôt et placement du Québec (CDPQ), which Lassonde praised for its resource funding, replied to emails seeking comment. The Canada Pension Plan (CPP), the Ontario Teachers’ Pension Plan (OTPP), the Ontario Municipal Employees Retirement System (OMERS), and the PSP didn’t reply or declined to speak.

“CDPQ is active in the mining sector in Quebec and Canada and has an investment team dedicated to the sector,” Kate Monfette, the pension’s media director, said by email. “Among other things, with a fund like Sodémex which supports exploration projects, we remain on the lookout for developments and opportunities in the mining and materials ecosystem. Our priority is to focus on the most promising companies in order to help them develop while generating a return for our depositors.”

British Columbia Investment Management (BCI) said it invests 29.4% in Canada and referred other inquiries to its annual report. OMERS said it wouldn’t comment on the topic.

Canada should consider Australia’s example, Lassonde and Giustra said. Its pensions, which are called superannuation funds, hold A$3.5 trillion (C$3.1 trillion), the third-largest amount behind the US and the UK. Domestic equities make up 21.9% of their assets. The large stakes prevent foreign takeovers, the entrepreneurs argued.

“That’s what keeps their domestic mining industry alive,” Giustra said. “We’re a comparable country in terms of how prolific our mining opportunities are, same as Australia, and we don’t have that same opportunity.”

Letko Brosseau says Canada’s top eight pension funds have invested more in China than in Canadian companies: C$88 billion versus C$81 billion. CPP has 2% in domestic shares, BCI has 0.5% and OTPP has 0.1%, the firm says.

Economics urged

Giustra said mining CEOs must lobby pension funds with moral suasion for why they should invest in Canada and make an economic argument. With China’s current woes from property market turmoil and a long-term population decline in motion, its boom years are over and it’s time for Canadian pension funds to repatriate funds to the world’s second-largest country by landmass that has top-tier mining regulations.

Lassonde went further and said federal and provincial governments must legislate pension funds to increase their investments in Canadian resource companies. He’s backed Letko Brosseau’s presentations to finance ministers in BC and Ontario as well as to officials in Ottawa.

“We’re trying to get to the decision makers and trying to make them understand what Canada is losing by doing nothing,” he said. “They created these funds, it’s in their power to legislate how these funds are managed.”

Giustra, who heads private equity firm Fiore Group invested in Aris Gold (TSX: ARIS) with mines in Colombia, and Ontario-focused explorer West Red Lake Gold Mines (TSXV: WRLG), said Canadian asset managers slashed their non-pension dedicated mining funds to C$2.8 billion in 2022 from C$16 billion in 2010.

“There’s just no source of capital, the industry starves,” he said. “You don’t have the seniors funding them, the pension funds aren’t there and we’ve lost the traditional mining funds here as well.”

Lassonde, who led a group of investors assembling an offer in May for Teck’s coking coal assets that was later beat by Glencore, said he approached BCI and Ontario pensions for input but got no response.

“If you want steel and you want the lowest carbon-emitting steel in the world, it’s that coal, OK, and there was nobody to talk to,” he said. “In Australia, we could have done this deal in about five days.”