'MAYBE'TECH

Mobile Carbon Capture in Shipping is Feasible

Mobile carbon capture in shipping is technically feasible and has a long term role to play in meeting the industry’s decarbonization targets.

That’s according to a new feasibility study conducted by the oil and gas climate initiative (OGCI) and Stena Bulk, an international tanker owner and operator. The study found, however, that high operational and capital expenses would be involved in any deployment and recommended further work should be done to compare costs of carbon capture against other long-term marine carbon dioxide reduction technologies.

“The study’s findings demonstrate that marine carbon capture can play a role in meeting the International Marine Organizations (IMO) 2050 target of reducing emissions from the industry by 50 percent compared to 2008 baselines,” a statement published on the OGCI’s website noted.

“The decarbonization of shipping is a critical part of achieving global pathways to net zero. Transportation contributes 24 percent of global energy-related greenhouse gas emissions and around 10 percent of that total comes from international deep-sea shipping,” the statement added.

“The results have encouraged the team to pursue a demonstration to validate their assumptions and uncover further opportunities,” the statement continued.

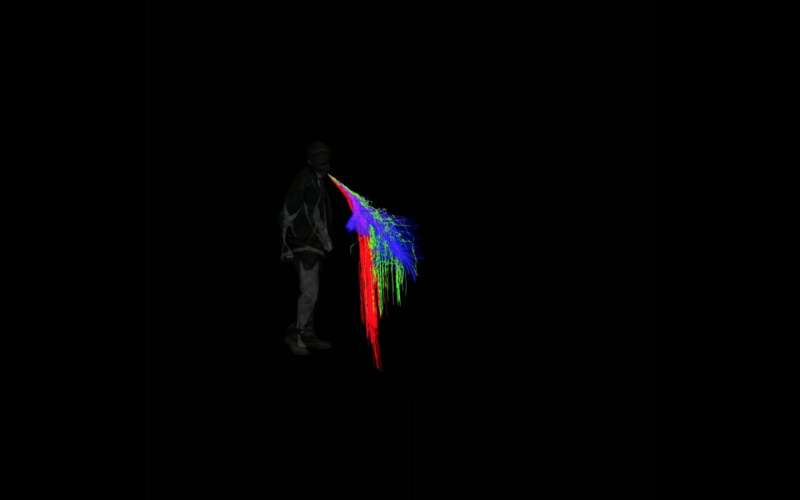

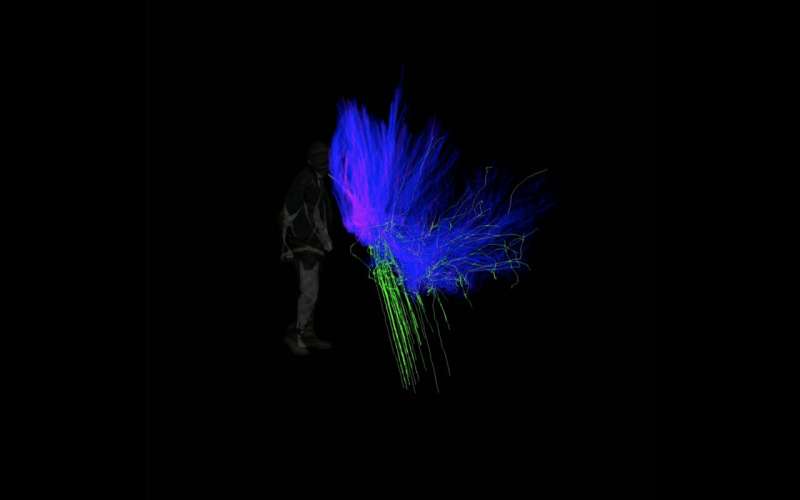

Launched in October last year, the study investigated the potential of capturing carbon from the exhaust gases of the large internal combustion engines that large ships predominantly use for propulsion.

A range of factors including energy balances, fundamental physics and integration challenges were assessed using a Suezmax ship. The study noted that the team chose the Suezmax because it offered the highest potential impact if successful, even though it represented the greatest technical challenge.

The OGCI describes itself as a CEO-led initiative that aims to accelerate the industry response to climate change. Members comprise Saudi Aramco, BP, Chevron, CNPC, Eni, Equinor, ExxonMobil, Occidental, Petrobras, Repsol, Shell and TotalEnergies.

In October this year, the OGCI published its updated performance data, covering the four years to 2020. According to the data, absolute upstream and downstream methane emissions fell 18 percent in 2020, and 33 percent since 2017, carbon intensity fell eight percent in 2020 and 14 percent since 2017, and upstream flaring emissions fell 20 percent in 2020 and 29 percent since 2017.

In September, the organization updated its 2025 carbon and methane emission intensity targets, which now have a potential additional saving of around 50 million tons of greenhouse gases per year, the OGCI highlighted.

The costs of installing carbon capture systems onboard revealed

A feasibility study conducted by the Oil and Gas Climate Initiative (OGCI) and Swedish tanker owner Stena Bulk shows the costs involved in installing carbon capture devices on ships. The study makes clear that such technology is feasible – something already demonstrated at sea in Japan by Kawasaki Kisen Kaisha (K Line) earlier this year – but it comes at quite a price, both in terms of installation and operating costs.

The costs for installation come in at around $30m for a system capable of capturing 90% of all CO2 emitted at sea (see chart below), while annual operating costs for such a system are estimated to be in excess of $2m a year, essentially adding another 25% to a ship’s annual operating expenses.

Despite the costs, the results from the OCGI/Stena Bulk study have encouraged the team to pursue a demonstration to validate their assumptions and uncover further opportunities.

Onboard CO2 storage developments are making plenty of headlines this year. Dutch scrubber manufacturer Value Maritime is installing a CO2 capture and storage unit on a 1,036 teu boxship, Nordica, belonging to Visser Shipping.

In South Korea, meanwhile, Daewoo Shipbuilding & Marine Engineering (DSME) has developed a technology to store CO2 captured in ship engine emissions. The South Korean yard said it plans to commercialise the technology as soon as possible.

It was also recently announced that Wärtsilä Exhaust Treatment and Solvang, a Norwegian shipping company, have agreed on a full-scale pilot retrofit installation of a CCS system on one of Solvang’s ethylene carriers, the 21,000 cu m Clipper Eos.