Boeing, Nucor spearhead efforts to build protective gear for health care workers

A Boeing worker shows the plastic protective face shield the company has rapidly designed, in partnership with Seattle nonprofit Design that Matters. Boeing delivered its first donated shipment of 2,300 face shields Friday to the federal government.

JOANNA WINGBERMUEHLE | BOEING

By Andrew McIntosh – Staff Writer, Puget Sound Business Journal

Apr 10, 2020

Two manufacturing heavyweights, jet maker Boeing and steel maker Nucor, have stepped up to design, manufacture and donate clear protective face shields for health care workers battling the COVID-19 pandemic.

The shipments address shortages of personal protective equipment across the United States.

Boeing's Puget Sound facilities in Auburn, Everett, Renton, and Tukwila, as well as Portland, have joined a companywide effort to make 3D-printed face shields for hospitals and frontline medical professionals fighting the pandemic, in coordination with the Federal Emergency Management Agency (FEMA).

Boeing said an initial shipment of 2,300 face shields was delivered to the Department of Health and Human Services Friday morning, hours after it was reportedly weighing plans to cut 10 percent of its 161,000 workforce.

Howard Rolleston, a Boeing additive manufacturing innovation cell leader in Philadelphia, said “people have been coming out of the woodwork” to volunteer on the jet maker's protective face shield for healthcare workers project.

FEMA will now deliver the shields to the Kay Bailey Hutchison Convention Center in Dallas, an alternate care site that's been created to treat patients with COVID-19.

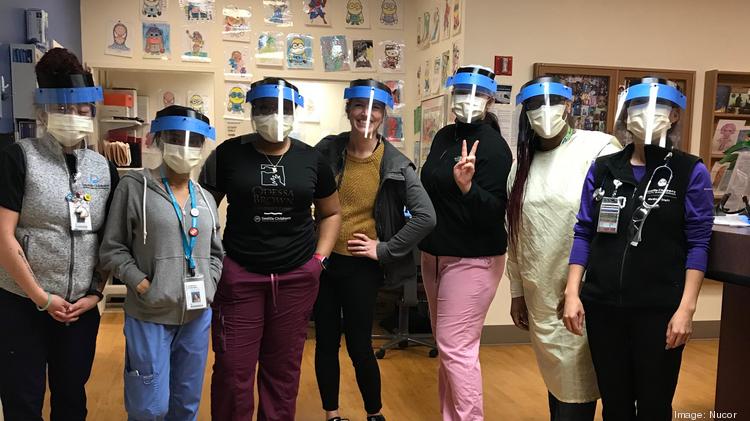

Nucor workers at the company's West Seattle facility have also designed and produced shields. Workers donated their first batch of 20 to the Providence Mount St. Vincent assisted living facility for seniors in that part of the city on April 2. "The Mount" is a 300,000-square-foot facility in Seattle that employs nearly 500 workers on its four-city-block campus.

Since then, and with community support, the Seattle engineers and others for the Charlotte-based steel maker have now made and delivered around 500 face shields to area hospitals, clinics, and care facilities, Nucor Seattle Environmental Manager Patrick Jablonski said.

After the early effort was highlighted by the West Seattle Blog, several area high schools, technical schools and local residents stepped forward, loaning idle equipment and personal equipment to assist the effort at the steel mill, Jablonski said.

Engineers and other staffers at Nucor West Seattle are making face shields, as seen here, that are being donated to health care facilities. After learning of their efforts, Puget Sound region schools have loaned equipment to the group to increase production.

NUCOR WEST SEATTLE

Nucor now estimates it can make around 100 face shields per day and that's growing. Its school partners include: Franklin Pierce School District, West Sound Tech, Seattle Christian, the Chehalis School District, and Tacoma School District, Jablonski said.

"When our community learned of this effort, they stepped up to help and we have gone from 100 face shields in a week to about 100 face shields per day," he said. "We are proud to be able to use our resources to contribute to solutions, but we are even more humbled by the response and immediacy with which our neighbors acted to help. We are all in this together.”

Nucor says its engineers who specialize in additive manufacturing are also now researching and designing various forms of respirator components that can be fitted with household media like coffee and vacuum filters.

Meanwhile, Boeing said it partnered with Design that Matters, a Redmond-based nonprofit group, on a design, which includes a 3D-printed frame with an adjustable headband. That allows the Boeing version of the clear plastic face shield to be easily snapped onto the frame.

Two major Boeing suppliers are playing important roles on the volunteer project, the jet maker said. Solvay is supplying clear film for shields. Its composite materials division has done business with Boeing for decades. Trelleborg Sealing Solutions, another longtime supplier, is donating straps needed for adjustable headbands.

Eaton and Regional Manufacturing Partners Support Ohio Medical Workers with 360,000 Face Shields in Battle Against New Coronavirus

Business Wire April 9, 2020

Eaton leverages manufacturing expertise, 3D printing capabilities to rapidly develop face shields and help address critical protective equipment shortages

Collaboration with Thogus and Cleveland’s Manufacturing Advocacy and Growth Network helps scale production, boost Ohio’s crisis response inventory

The global COVID-19 crisis is placing unprecedented demands on government and healthcare organizations, driving a critical need for front line workers’ access to personal protective equipment (PPE). Power management company Eaton (NYSE:ETN) is using its manufacturing, 3D printing expertise and partner network to fulfill a JobsOhio order for rapid production of 360,000 reusable face shields to strengthen the state’s fight against the virus.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20200409005733/en/

Eaton used 3D printing to address critical protective equipment shortfalls. Hundreds of thousands of face shields are being supplied to hospitals in the fight against COVID-19. (Photo: Business Wire)

Eaton collaborated with multiple hospitals and Cleveland’s Manufacturing Advocacy and Growth Network (MAGNET) to optimize the face shield design for production. Now, Eaton is working with Thogus, a local family-owned custom plastic injection molder, to rapidly produce the critical equipment at scale.

"Ten business days ago, this project was just a concept. Today, we’re moving forward with production and looking to expand further," said Michael Regelski, senior vice president and chief technology officer, Electrical Sector at Eaton. "By leveraging our advanced manufacturing capabilities and strong network of partners, we’re helping Ohio quickly respond to current inventory challenges and maximize accessibility of critical PPE resources for front line teams combatting COVID-19."

Eaton’s additive manufacturing capabilities are instrumental to fast-paced design incorporating customer feedback and ability to easily scale production to meet the immediate needs of communities around the world.

Learn more about how Eaton is joining the fight against COVID-19.

Eaton’s mission is to improve the quality of life and the environment through the use of power management technologies and services. We provide sustainable solutions that help our customers effectively manage electrical, hydraulic, and mechanical power – more safely, more efficiently, and more reliably. Eaton’s 2019 revenues were $21.4 billion, and we sell products to customers in more than 175 countries. We have approximately 97,000 employees.

View source version on businesswire.com: https://www.businesswire.com/news/home/20200409005733/en/

No comments:

Post a Comment