Algae Biofuel Back From Dead, Now With Carbon Capture

Algae biofuel could have another moment in the sun, now that more federal dollars are pouring into carbon capture-and-recycling technology.

Algae biofuel could have another moment in the sun, now that more federal dollars are pouring into carbon capture-and-recycling technology (photo by Dennis Schroeder, NREL).

ByTina Casey

Published 2 days ago

Algae biofuel stakeholders have been stuck in the doldrums for years, but in an odd twist of fate, the fossil fuel industry could help algae make a comeback. Apparently the new plan is to pair algae farming with waste carbon from gas power plants and other industrial operations. In addition to biofuel, algae farming can also produce animal feed, fish food, nutritional supplements and toiletries for people, and bioplastic products.

Why Algae Biofuel?

CleanTechnica spilled plenty of ink on the area of algae biofuel research some years ago, during the Obama administration. Unlike other energy crops, algae can be grown in ponds or human-made structures without taking arable land out of circulation, and it has a rapid growth-to-harvest cycle. The high oil content of certain strains of algae is another leading attraction, and the algae R&D pathway can lead in a carbon negative direction.

On the down side, figuring out an economical way to cultivate algae and extract the oil at an industrial scale is a challenging endeavor, especially when the over-arching goal is to reduce carbon emissions rather than adding them.

The picture was looking bright in the early 2000s, up through the Obama administration. However, by the time former President Obama left office in 2016, oil prices were crashing. The relatively low cost of petroleum seemed to put the idea of a bioeconomy fueled by algae biofuel to bed.

Nevertheless, the Energy Department’s National Renewable Energy Laboratory was among those continuing to invest in algae research projects, and the algae field continued to branch off into new angles. In 2018, for example, the Energy Department was funding the algae bioplastics angle. In 2020 researchers were exploring the idea of hooking up with high speed 3-D printing. The Mars mission has also sparked a new burst of interest in the algae biofuel field.

Carbon Capture To The Rescue

In January of this year the Energy Department’s Bioenergy Technologies Office (BETO) launched the new AlgaePrize competition for students, aimed at developing “the next generation of bioeconomy professionals by expanding novel solutions to production, processing, and new product development on the way to gigaton-scale algae commercialization for fuel, food, products, and carbon dioxide utilization/sequestration.”

If you caught that thing about carbon dioxide, that’s where the happy dance for natural gas stakeholders comes in. Carbon capture from flue gas could turn out to be a value-added element that improves the bottom line for algae farming.

That’s where BETO seems to be heading. Last week the office announced a $16.5 million round of funding for six algae projects related to carbon dioxide capture.

The six projects were selected for their potential to demonstrate an improvement in carbon capture by algal systems leading to biofuels and other products, while also cutting costs and decreasing overall greenhouse gas emissions.

“Algae can grow on waste CO2, functioning as a carbon sink. This algae biomass can then be used to create low or no-emissions biofuels and bioproducts which displace GHGs,” BETO noted.

Natural Gas Hearts Algae Biofuel

Not all six of the new BETO-funded projects are focusing on carbon captured from flue gas. The Colorado School of Mines, for example, plans to put its pond-grown algae system through its paces using concentrated carbon dioxide from direct air capture.

Another awardee, Colorado State University, is working on an algal system that functions efficiently on atmospheric carbon.

Three of the other awardees are focusing on carbon dioxide from industrial fossil energy users including power plants: Dioxide Materials, MicroBio Engineering, and the University of Maryland’s Center for Environmental Sciences. A fourth awardee in the point source class is Global Algae Innovations, which is focusing more specifically on flue gas from a naphtha-fired power plant.

If the biofuel angle doesn’t work out at commercial scale, other aspects of the algae biofuel market could come into play.

Market analysts are forecasting growth in the algae market in the coming years. Consumers are on the prowl for healthy diet supplements, especially among the up-and-coming generation.

“Rise in the acceptance of algae-based food products and a growing popularity of vegan food are expected to emerge as trends in the algae market. Algae are already widely employed in bioplastics, cosmetics, food, bio-packaging, biofuel, and pharmaceutical and nutraceutical products,” observes the firm Transparency Market Research.

The Long Algae Biofuel Game Of ExxonMobil

All this activity puts the on-again, off-again algae biofuel journey of ExxonMobil into perspective.

ExxonMobil spearheaded the charge into shale gas after the Bush Administration lifted Clean Water Act regulations in 2006, and the company continued to double down on gas acquisitions even as prices plummeted.

The pell-mell rush into shale gas looked like a bad bet for any number of reasons, especially when gas prices cratered after 2005. Among other problems for the company, the issue of stranded fossil energy assets also began to rise in 2014 as shareholder activists demanded transparency. The Covid-19 pandemic didn’t help matters much. As of last year, the company was in so much financial trouble that it fell off the Dow Jones Industrial Average.

On top of all that, ExxonMobil’s notorious role in the repression of climate science is coming home to roost, now that climate-related catastrophes are impacting populations around the world and here in the US, too.

Nevertheless, gas is soaring again and ExxonMobil has a chance to wriggle back up on top, partly due to its interest in algae biofuel.

ExxonMobil has been investing in algae biofuel research since at least 2009, though its activity in the commercial aspect of algae farming has not been a straight line since then. In 2013, for example, the company seemed to lose interest in making quick entry into the algae biofuel market. Instead, it pivoted into foundational research under a 4-year contract with the firm Synthetic Genomics, Inc.

By 2018, the company was also collaborating with the Colorado School of Mines and Michigan State University on algae biofuel research, but a clear pathway to commercial-scale algae biofuel had yet to emerge.

The carbon capture angle could be a game changer. The outlook for algae biofuel looked gloomy indeed several years ago, but now that more federal dollars are pumping into point-source carbon capture the prospects have brightened.

ExxonMobil’s own investments in carbon capture could also come into play. By 2016, the company was already dipping into the idea that a carbon recycling solution at power plants could make a better case for carbon capture than the capture-and-sequestration model.

Next Steps For Algae

ExxonMobil, for one, is excited. The company lists the following benefits compared to corn ethanol and other biofuels made from land-based energy crops:Unlike making ethanol and biodiesel, producing algae does not compete with sources of food, rendering the food-vs.-fuel quandary a moot point.

Because algae can be produced in brackish water, including seawater, its production will not strain freshwater resources the way ethanol does.

Algae consume CO2, and on a life-cycle basis have a much lower emissions profile than corn ethanol given the energy used to make fertilizer, distill the ethanol, and to farm and transport the latter.

Algae can yield more biofuel per acre than plant-based biofuels – currently about 1,500 gallons of fuel per acre, per year. That’s almost five times more fuel per acre than from sugar cane or corn.

That’s all well and good, but it’s about time for ExxonMobil and other fossil energy stakeholders to stop digging more carbon up from the ground and start taking giant steps towards a more sustainable energy profile.

Capturing carbon dioxide at power plants is a step in the right direction, but it doesn’t change anything in terms of the local environmental impacts of fossil energy extraction, and it doesn’t make a dent in the amount of fugitive emissions escaping from drilling sites, transportation networks and storage facilities.

To the extent that algae farming at gas power plants enables more gas extraction, it’s just another form of greenhouse gas whack-a-mole.

Either way, it looks like algae farming at power plants has a window of opportunity. Last November ExxonMobil re-upped its collaboration with Synthetic Genomics, under the new name of Viridos. If you have any thoughts about that, drop us a note in the comment thread.

Follow me on Twitter @TinaMCasey.

Photo: Algae bioreactor for biofuel and other products (credit: Dennis Schroeder, NREL).

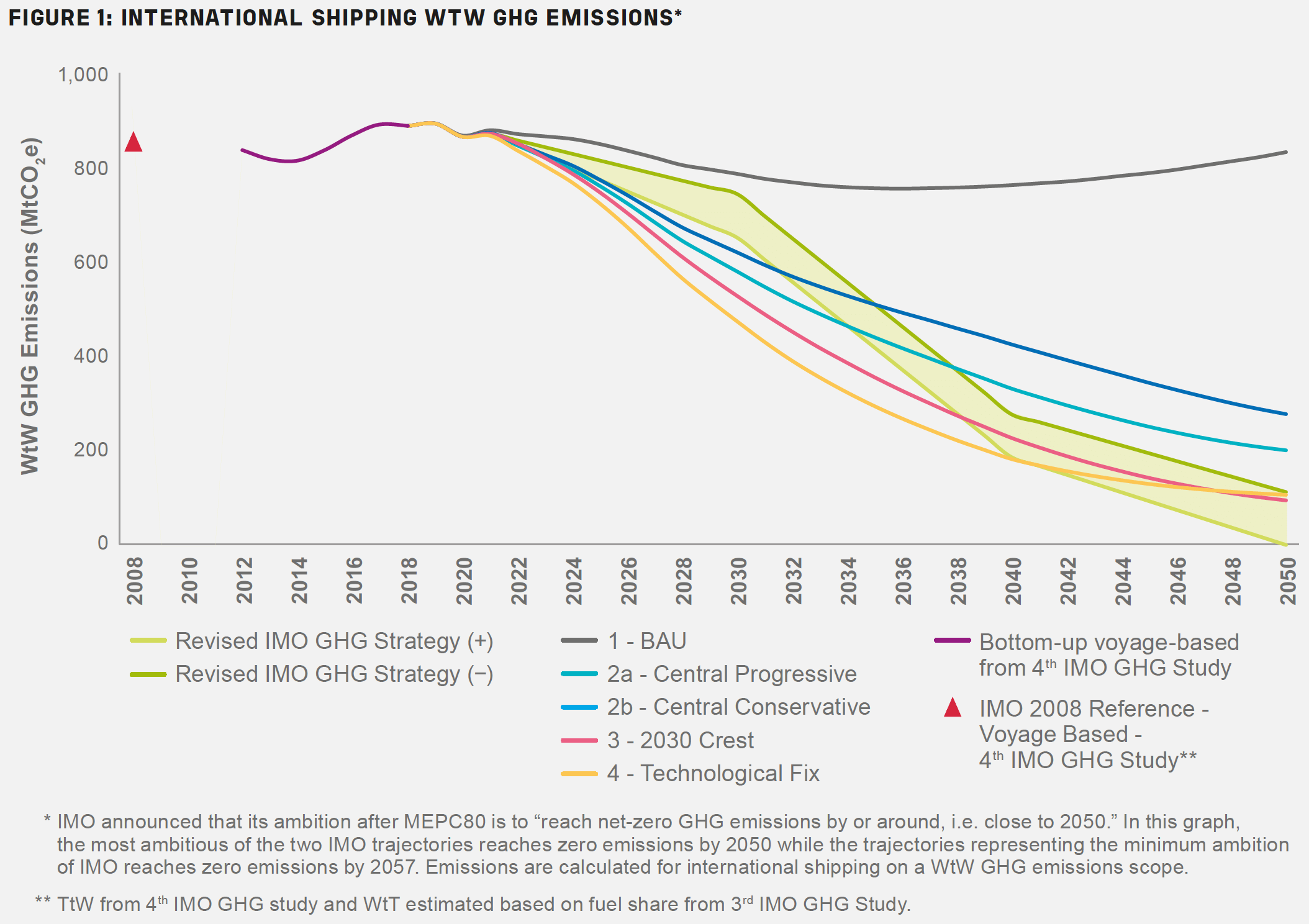

The maritime industry is facing an ever-tightening regulatory environment in its efforts to achieve its ambitious net-zero target by the middle of this century. For meaningful progress to be achieved, the industry needs two things: practical solutions, together with a detailed understanding of the actual impact of various long and short-term measures on the industry’s future decarbonization pathway.

The maritime industry is facing an ever-tightening regulatory environment in its efforts to achieve its ambitious net-zero target by the middle of this century. For meaningful progress to be achieved, the industry needs two things: practical solutions, together with a detailed understanding of the actual impact of various long and short-term measures on the industry’s future decarbonization pathway.