Healthy buildings can help stop Covid-19 spread and boost worker productivity

KEY POINTS

Healthy buildings have become the latest enticement to bring employees back into the office, and the first step is to make sure ventilation systems are working the way they are supposed to.

Improving indoor air quality in offices could add as much as $20 billion annually to the U.S. economy, according to estimates from the Lawrence Berkeley National Laboratory.

“I don’t think business people realize the power of buildings to not only keep people safe from disease but to lead to better performance,” said Joseph G. Allen, Harvard’s T.H. Chan School of Public Health associate professor.

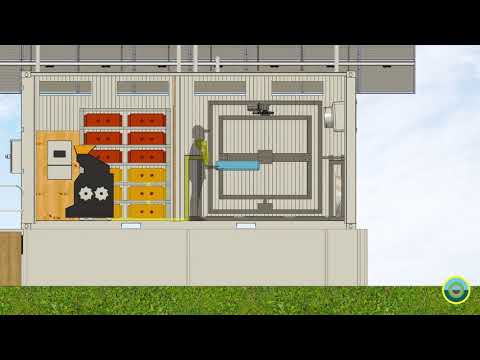

VIDEO 4:33Harvard’s Joseph Allen on indoor air quality, employee health and productivity

Any C-suite executive looking to lure workers back into the office has likely spent more time thinking about indoor air quality and ventilation over the past year-and-a-half than at any other point in their pre-pandemic life.

That’s because healthy buildings have become the latest enticement to bring employees back into the office. As people slowly return to in-person work, they’re naturally concerned with how safe they’ll be. Companies continue to reassure workers that desks, computer keyboards, elevator buttons, and every other public surface are being sufficiently sanitized.

But now they’re also paying closer attention to how healthy the air is inside those buildings — and the impact this can have not only on preventing the spread of Covid-19 and other respiratory ailments but how air quality can affect cognitive function.

“I don’t think business people realize the power of buildings to not only keep people safe from disease but to lead to better performance,” said Joseph G. Allen, Harvard’s T.H. Chan School of Public Health associate professor and director of the Harvard Healthy Buildings program at the CNBC Workforce Executive Council summit on Wednesday. “Greater ventilation leads to significantly better cognitive function performance of employees. It’s good for worker health and productivity.”

“Droplet dogma is over”

Allen said the increased interest in the air quality inside buildings stems from a better understanding of how Covid-19 spreads. Cleaning surfaces and obeying the six-foot distancing rule made sense when the belief was that the virus spread through droplets emitted when we coughed or sneezed and these droplets couldn’t travel further than six feet.

The reality is that Covid-19 is spread through respiratory aerosols that travel well beyond six feet, Allen said. “When we’re talking, coughing, sneezing, or just breathing, we’re constantly emitting respiratory aerosols of different sizes,” he added. “If we’re infected, those particles carry the virus and can travel across any room and stay aloft for hours. The droplet dogma is over.”

An under-ventilated room or building means these respiratory aerosols will build up and can infect someone well beyond that six-foot distance. “All of the big outbreaks we’ve seen have the same characteristics,” Allen said. “Time indoors in an under-ventilated space. It doesn’t matter if it’s spin class, choir practice, or a restaurant. It’s the same fundamental underlying factors that are driving transmission.”

Businesses can take action to counter this, Allen said. “Just like we’ve made great gains in public health around sanitation, water quality, and food safety, indoor air quality is going to be part of that conversation moving forward,” he said.

Employees wear protective masks at a JLL office in Menlo Park, California, U.S., on Tuesday, Sept. 15, 2020.

David Paul Morris | Bloomberg | Getty Images

Giving buildings a tune-up

The first step is for building managers to determine what systems are in place and if they are operating as they were designed to do. “It seems obvious, but oftentimes we put equipment in and then leave it for 10 or 15 years and never give it a tune-up like we do our cars,” Allen explained.

Maximizing the amount of outdoor air coming into the building is another step to take. And finally, Allen said air filters should be upgraded to what’s called MERV 13. (MERV stands for minimum efficiency reporting value.) He explained that a typical building has a MERV 8 filter that captures about 20% of airborne particles. A MERV 13 filter will capture closer to 90% or more of those particles.

Not only will these higher-grade filters improve air quality to help reduce the spread of viruses, but they can also help workers improve their performance.

Allen’s team at Harvard recently released a study looking at workers from around the world for a year. Each had air quality sensors placed at their desks. A custom-designed smartphone app enabled these workers to take brief cognitive function tests. Allen found that the people with better air ventilation and lower particle levels performed significantly better on these tests than people working in areas where the air quality is worse.

“The beautiful thing about all this is that healthy building strategies help protect against infectious disease, but they’re also good for worker health, productivity, and performance,” Allen said.

In his 2020 book, “Healthy Buildings: How Indoor Spaces Drive Performance and Productivity” which he co-wrote with Harvard Business School lecturer John D. Macomber, Allen said they show how better air quality and ventilation can lead to bottom-line gains for businesses. His Harvard research and financial simulations found that the benefits of higher ventilation alone are estimated to be between $6,500 and $7,500 per person, per year. In an April 2020 Harvard Business Review article that he co-authored with Macomber, Allen cites researchers at Lawrence Berkeley National Laboratory estimating that improving indoor air quality in offices could add as much as $20 billion annually to the U.S. economy.

“Since the late 1970s, in response to the global energy crisis, we started to tighten up our buildings and in the process choked off the air supply in an effort to conserve energy,” Allen said. In doing so, we ushered in the sick building era.

“It’s no surprise that we have high levels of indoor air pollution and sick buildings where people can’t concentrate in conference rooms and constantly feel sleepy at work,” he said.

And contrary to what many think, it’s not just new, modern buildings that can be health-focused. “Any building can be a healthy building and it’s not hard to do and it’s not that expensive,” he added. “In fact, I would argue that healthy buildings aren’t expensive. Sick buildings are what’s expensive.”