Bloomberg News | June 20, 2022 |

Credit: Nippon Steel Corp.

Nippon Steel Corp. is prepared to make more investments in coal mines after the energy source surged in price, as Japan’s biggest steelmaker looks at ways to stabilize the supply of one of its key raw materials.

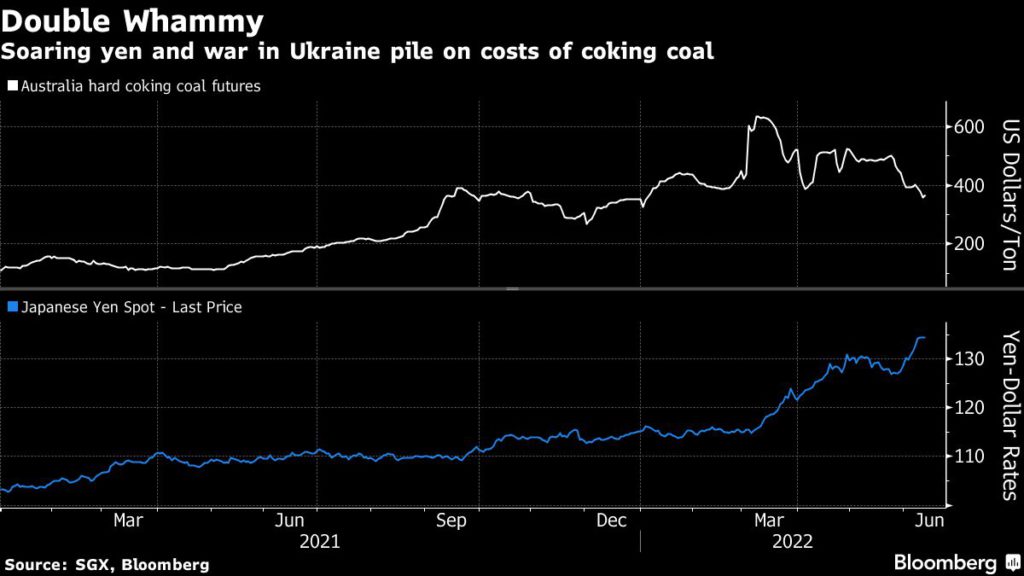

International prices of coking coal, the variety shoveled into blast furnaces to manufacture the alloy, have spiked to unprecedented levels in the wake of Russia’s invasion of Ukraine. At the same time, Japanese steel mills, most of which are reliant on imports, are grappling with ballooning costs after a dramatic slide in the value of the yen.

It’s a dynamic that’s led Nippon Steel to study whether investing further in coal projects makes sense, particularly as miners come under pressure to divest those assets because of fears over global warming, Kiichi Yamada, the general manager of the company’s raw materials division, said in an interview in Tokyo last week.

Nippon Steel currently has minority stakes in six coking coal assets, mostly in Australia, including the Moranbah North project led by Anglo American Plc with production capacity of 15 million tons a year, according to the company’s annual factbook.

Yamada didn’t give any details on possible new investments. In the news, Japanese trading firm Mitsui & Co. has begun seeking buyers for its 20% stake in a joint venture that operates coking coal mines in Queensland, according to a report in the Australian Financial Review, which didn’t name its sources.

Nippon Steel’s potential move to bolster its upstream presence underscores how energy price inflation is forcing companies to prioritize their short-term operational needs over longer-term ambitions to cut carbon emissions. Manufacturing steel is intensely pollutive. In both China and Japan, the world’s no. 1 and no. 3 producers, it’s estimated to account for around 15% of each country’s total emissions.

For its part, Nippon Steel has promised to become carbon neutral by 2050, a plan that involves making more steel from melting scrap and replacing coal with hydrogen. The first means an expensive switch to electric arc furnaces, while the second involves substantial investment in a technology that’s promising but still uncertain. Mindful of the costs of getting to net-zero, the company has lobbied the government for billions of dollars in state aid.

In the meantime, coal mines that were being shunned for their baleful impact on the atmosphere are being given a new lease of life. Nippon Steel’s interest coincides with BHP Group’s U-turn just last week on its plan to exit from thermal coal, the kind used by power plants. The Australian mining giant’s about-face came after surging prices made the assets more valuable and a shift in investor attitudes eased pressure on the company to stop digging up the dirtiest fossil fuel.

Still, Yamada expects the market for coking coal to remain tight. It’s mined in fewer places around the world than the more ubiquitous and cheaper thermal kind. Japan bought about 70 million tons last year, over half of which came from Australia. Moreover, the broad shift to net-zero makes it harder for miners to finance new projects, entrenching the dominance of producers like BHP Group.

Prices are more than twice where they were a year ago, and given the limited opportunities to expand supply, “it’s structurally difficult for coking coal prices to fall,” Yamada said.

The Japan Iron and Steel Federation, which represents more than 100 producers and traders including Nippon Steel, has warned there’s a mismatch between steel prices and the cost of the raw material, and has set up a team to investigate. In India, the second-biggest producer, the steel industry is seeking government help to check the soaring cost of the raw material, the Business Standard newspaper reported last week.

Part of the problem, according to Yamada, may be how coking coal prices are reflected in the market. Five years ago, the company switched to using price assessments as the basis for procuring supply because the spot market had grown too volatile. But China’s ban on imports of Australian coal in 2020 has significantly cut the number of deals struck and left pricing less liquid. It may mean that prices don’t “fairly reflect the supply-demand balance,” he said.

Nippon Steel has begun discussing the problem with its suppliers. Resolving the issue will involve either enhancing the credibility of index-linked pricing or finding an alternative, Yamada said.

(By Masumi Suga, with assistance from Swansy Afonso)