Push for ESG price premiums may reshape global critical minerals markets

As low nickel prices force Australian miners to scale back production, some have called for an ESG premium on low-carbon production that would help Western producers compete with cheaper, but more polluting Indonesian metal.

But are customers willing to pay more for low-carbon nickel? Some analysts say yes — under certain conditions.

“If the market sees a benefit in paying a premium for certain supplies then it will,” Jim Lennon, managing director of commodities at Macquarie Group, told The Northern Miner in an interview. “A buyer would be willing to pay a premium if they can see an economic benefit in using that product, such as receiving a government subsidy or securing a sale of a ‘greener’ electric vehicle.”

The price of nickel has been on a downtrend since late 2022 when it was $33,575 per tonne ($15.23 per lb.). The price on Tuesday was $17,678 per tonne ($8.02 per lb) and in February dipped as low as $15,850 per tonne ($7.19 per lb).

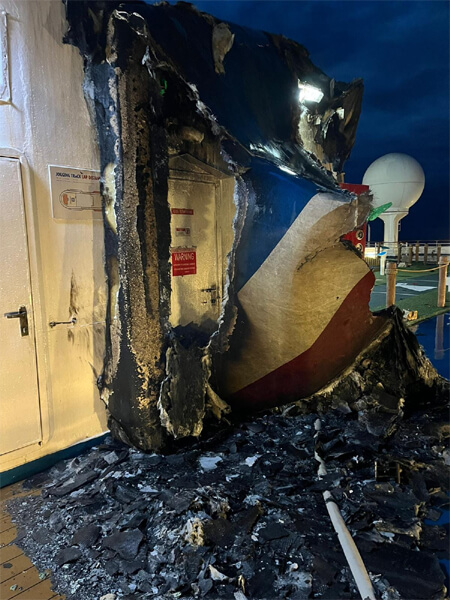

The price doldrums have prompted Wyloo Metals and BHP (ASX: BHP) to suspend operations in Australia, with BHP announcing it would take a $2.5 billion impairment on its assets.

Given the devastation to its nickel sector, Australia has been the most vocal in creating new variable price brackets for low-carbon emissions nickel.

The idea for premium ESG pricing isn’t new. In fact, some experts argue that there’s already a premium.

Canada Nickel (TSX: CNC; US-OTC: CNIKF) CEO Mark Selby says people might be surprised to learn that price premia have already been paid for various North American products perceived as cleaner on Asian markets.

Selby notes that domestic premiums for certain materials have been sustained over several years, which might not be directly attributable to lower carbon footprints or ESG factors alone but could be influenced by a combination of factors, including local supply.

But this type of premium isn’t helping Australian nickel miners. And deliberately imposing an ESG premium would be a different story.

“The main challenge is defining what ‘ESG-compliant’ actually means,” Macquarie’s Lennon said.

It’s an obstacle that the London Metal Exchange (LME) is facing as it investigates and prepares for the potential emergence of premium pricing for low-carbon products on separate trading contracts.

Georgina Hallett, LME’s chief sustainability officer, says that there’s increasing interest from producers, consumers, and investors in establishing a price premium for metals produced with lower carbon footprints. However, defining what constitutes ‘low carbon’ or ‘green’ metals isn’t easy due to the lack of a standardized, universally accepted framework for measuring and verifying the environmental impact of metal production processes.

“The aim is to build a robust framework that supports the gradual introduction of sustainability-linked pricing mechanisms while ensuring broad market participation and avoiding undue disruption,” Hallett said. “By taking a step-by-step approach, the LME hopes to align the interests of various stakeholders and drive meaningful progress toward the integration of sustainability into the global metals market.”

Free market forces

Lennon suggests that establishing a special low-carbon contract for metals on the LME is unnecessary. This is because the prices for different products are already determined by normal market activities, such as supply and demand. Just like prices for different metal shapes and origins adjust based on market conditions, the prices for products with various ESG qualities would naturally adjust in the same way.

“Exchanges don’t need necessarily to get involved since they can focus on ‘objective criteria for delivery (shapes, metal purity, etcetera) and leave the market to decide on ‘subjective’ factors such as value-in-use of different products/shapes and ESG,” Lennon said.

From an exchange perspective, like the LME, there is also a risk of damaging liquidity if they were to introduce multiple contracts. Compared with large commodity derivative markets, nickel is not particularly liquid and dividing this liquidity could reduce the usability of the market for some participants.

Lennon says markets will ultimately determine the outcome. Currently, nickel prices vary significantly between products depending on supply and demand.

Today’s primary nickel products that are LME deliverable include metal rounds, pellets, cut cathode, and full plate cathode. When delivered to LME warehouses, each product is assigned a warrant associated with it. When buyers want to take delivery from the LME, they are often willing to pay LME brokers a premium for warrants of a particular material shape or origin.

Similarly, other non-LME deliverable products, including intermediates (concentrates, mattes, MHP, MSP, etc.) or finished products (ferronickel, nickel pig iron, nickel sulphates, nickel chlorides, etc.) also sell at varying discounts or premiums to LME base prices. Lennon said these premiums/discounts can change dramatically due to changes in supply and demand.

For example, nickel pig iron was selling at a premium to the LME price at the start of 2022 and then had fallen to a discount of 40% to the LME by the first half of 2023.

“Product type, ESG, and country of origin are all important properties and presumably were factors that led major automakers to agree to term supply contracts with BHP and Vale in recent years. ESG was no doubt a factor in these negotiations,” Lennon said.

Canada Nickel’s Selby emphasized the importance of provenance tracing rather than setting up a formal two-tiered pricing system.

He points out that imposing a pricing mechanism before the market is ready can lead to inefficiencies, such as a benchmark that does not accurately reflect market conditions. He suggests letting the market sort it out.

“We will continue to observe the distinction between Western-supplied, clean, green nickel and the high-carbon, less ESG-compliant nickel from China and Indonesia,” he said. “As for the necessity of a formal pricing mechanism, it’s typically better if such mechanisms emerge naturally in the marketplace before establishing a formal platform for trading them.”

Aussie nickel rout

An increase in supply from Indonesia has cratered nickel prices, as the southeast Asian nation boosted production of refined and semi-refined nickel, mainly on the back of an export ban on raw ore, which led to massive investment from China in new processing plants, according to Lennon.

Indonesia has become the dominant nickel producer, accounting for 55% of global supply, up from 7% in 2015, according to Bank of America data.

Higher-cost Australian supply can’t compete.

Australia’s federal resources minister Madeline King responded to the raft of nickel suspensions by adding nickel to the country’s critical minerals list, enabling industry access to part of the A$4 billion ($2.6 billion) federal funding earmarked for critical energy transition minerals exploration and development.

“Prices paid for Australian minerals need to recognize the high ESG standards the Australian industry adheres to and the fact that Australian workers enjoy good working conditions and the highest safety standards.”

At PDAC she noted that Canada and Australia have agreed to jointly advocate for robust ESG credentials to be built into global, transparent and traceable critical minerals supply chains.

Laying foundations

The LME has been considering introducing a premium for green or sustainable metals since it released a 2020 white paper on the topic, Hallett noted.

In 2021, the LME collaborated with Metalshub, a digital metals procurement platform which facilitates buyers’ access to the physical metal that meets specific attributes, including carbon intensity and other ESG criteria. The LME said that low-carbon nickel, classified as producing 20 tonnes of carbon dioxide or less per tonne of nickel, could already be traded on Metalshub’s system.

The platform aims to allow market participants to specify and search for metals that meet specific sustainability standards, thereby fostering the emergence of a market-driven definition of ‘green’ metals.

Hallett says the critical missing component to formalizing a new price bracket is doing the less sexy but foundational work around how one measures emissions the same way across the industry to create an equal playing field for products in the value chain included in that new contract.

The LME has initiated several measures to promote sustainability within the metals market. One of the key initiatives is the development of metal-specific measurement methodologies, in collaboration with metal industry associations, to standardize measuring carbon emissions across different metals.

However, the LME is taking a deliberate approach to implementing a low-carbon pricing mechanism for nickel and other metals, given the still-evolving market for low-carbon metals.

“Our approach remains one of cautious optimism and pragmatic progression,” Hallett says. “We are committed to leading the industry towards a more sustainable future, understanding that real change is achieved not by rushing but by thoughtful, collective action.”