First Methanol-Fueled Tug Launches at Port of Antwerp

The world's first methanol-powered tugboat, the Methatug, was unveiled today in Antwerp. It is part of a series of projects known as FASTWATER, which aims to demonstrate the feasibility of methanol as a sustainable fuel for the shipping industry as well as the Port of Antwerp-Bruges' efforts to become a multi-fuel port.

The project was first announced in 2021 calling for the retrofitting of the engines aboard an existing port tug to become dual-dual capable of operating on methanol. In addition to the technical hurdles, port officials highlighted that they faced regulatory challenges. Rhine-based inland navigation craft must comply with the Central Commission for Navigation on the Rhine’s (CCNR) regulations, which had previously forbidden the use of methanol as a marine fuel. The port spent a year and a half to gain the necessary regulatory approvals.

The tug’s two engines were returned to the ship at the end of 2022 as the project progressed. The fuel supply and storage system had to also be created for the vessel as well as the supply chain for methanol. The tug was fitted with a tank to hold approximately 12,000 liters of methanol, which port officials said is enough for two weeks of operation.

Rechristened Methatug, the vessel is nearly 100 feet in length (29.5 meters) and is 584 tons with a 50-ton bollard pull capacity. The Swedish ship design agency ScandiNAOS led the project with the Belgian engine manufacturer Anglo Belgian Corporation supplying the two 8DAC dual-fuel medium-speed engines. The German company Heinzmann was responsible for the methanol injectors. Ghent University oversaw the emission monitoring program and the Canadian methanol supplier Methanex also participated in the trials. De Wit Bunkering will supply Methatug with methanol via truck-to-ship bunkering at the Port of Antwerp-Bruges Nautical Operational Cluster (NOC).

As the fifth-largest bunker port in the world, the Port of Antwerp-Bruges is demonstrating a range of alternative power sources as it works to transition for its decarbonization goals and meet the needs of the shipping industry. The port has also introduced Hydrotug 1, the first hydrogen-powered tug, and is currently working on an electrically powered tugboat which will be the first in Europe when it is introduced later this year.

Methatug was financed by the European research program Horizon 2020 and is part of the FASTWATER project. To demonstrate the feasibility of methanol as a sustainable fuel, the FASTWATER project includes the conversions to methanol propulsion of a pilot boat in Sweden, a river cruise ship in Germany, and a coastguard vessel in Greece in addition to the Antwerp tug.

Several other projects will follow also demonstrating methanol-fueled tugs. Work is underway in Turkey at the Sanmar shipyard on two dual-fuel methanol tugboats. They are being promoted as the world’s first large, purpose-built high bollard pull tugs fueled by methanol. They are expected to enter service in mid-2025 employed by Canada’s Horizon Maritime Services escorting tankers supporting the Trans Mountain Expansion Project between the Westridge Marine Terminal and the harbor limits of the Port of Vancouver, Canada.

Second Generation Intelligent Tugs for Tiajin Port

[By: Robert Allan]

In the morning of April 18, Tianjin Port held a naming ceremony for its two latest RAmparts 3500 ASD Tugs, Jingang Lun 36 and Jingang Lun 37, designed by Robert Allan Ltd. The ceremony meant the successful completion of the project that Robert Allan Ltd. began the concept development with the port technical department back in early 2022. The two tugs are the second generation of intelligent tugs for the port as part of the ambitious plan to create an intelligent port. The first generation of four tugs with intelligent-ship notation delivered in 2019 were also designed by Robert Allan Ltd.

During a six-day extensive sea trial, Jingang Lun 36 and Jingang Lun 37 completed comprehensive self-control auto navigation tests which included automatic searching, approaching, and accompanying a target vessel at sea. It is reported that this was the very first time a ship-handling tug has been equipped with this kind of system and approved by a Classification Society.

Main Particulars of Jingang Lun 36 and Jingang Lun 37 are:

- Length overall: 34.60 metres

- Beam, moulded: 11.20 metres

- Depth, moulded: 5.22 metres

The tugs were designed and constructed to comply with all applicable Rules and Regulations of CCS, with the following notation:

?CSA Tug; Ice Class B; Cyber Security(S); R2(D); i-Ship(M, E, I) ?CSM AUT-0

Tank capacities are as follows:

- Fuel oil: 60 m3

- Potable water: 40 m3

Carried out by the builder Jiangsu Zhenjiang Shipyard, sea trial results showed that both tugs met all of the requirements of the design by achieving a bollard pull ahead of 64 tonnes and a speed of 13 knots.

The fully customized design comes from a decade of cooperation between Robert Allan Ltd. and the Tianjin Port. Each of the eight crew members have their own cabin which is arranged to comply with the requirements of ILO MLC 2006. There were also specially designed pilot landing platforms provided to create a safe working environment for pilots. For the convenience of the crew, layouts of deck machinery, and machinery spaces were also designed in a similar way as the other tugs in the fleet with improvements learned from the previous operations.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

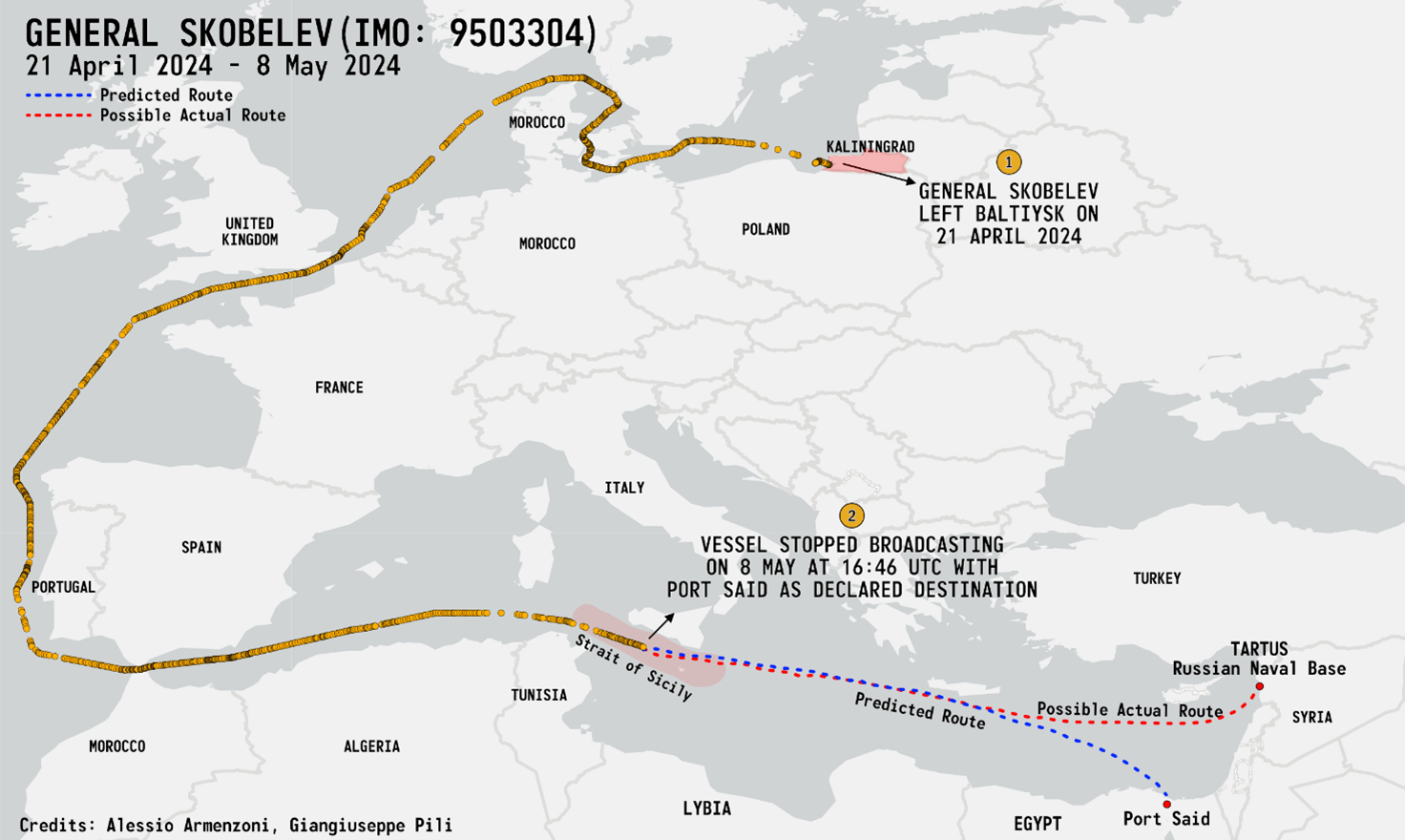

Fig. 1: General Skobelev's route from April 21 to May 8, 2024. Sources: AIS data provided by Global Fishing Watch, annotated by the authors.

Fig. 1: General Skobelev's route from April 21 to May 8, 2024. Sources: AIS data provided by Global Fishing Watch, annotated by the authors.

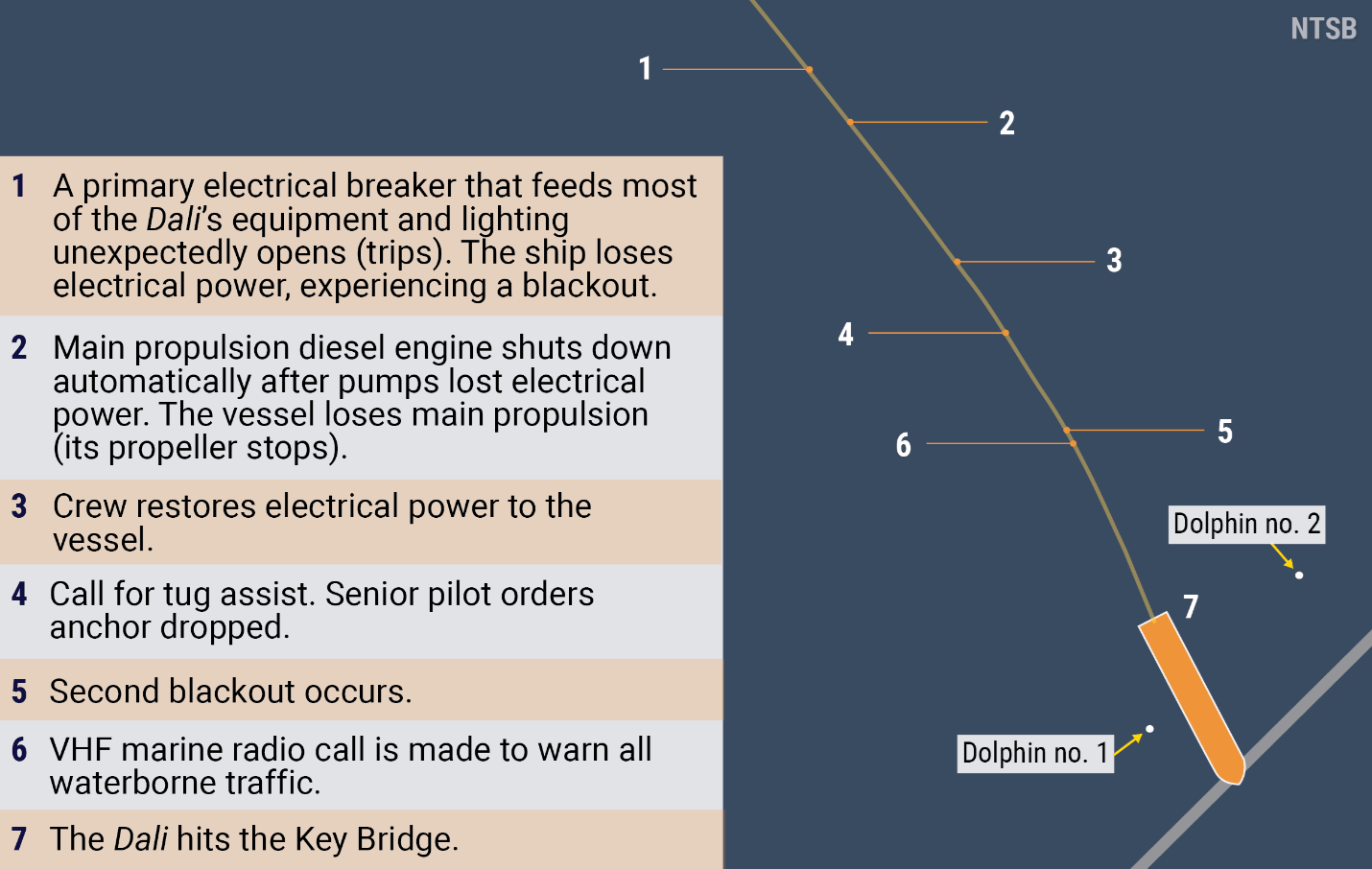

Overview of the accident timeline (NTSB)

Overview of the accident timeline (NTSB).jpg?ext=.jpg) Lundberg and Djuric sign the agreement between OKG and Hynion (Image: Hynion)

Lundberg and Djuric sign the agreement between OKG and Hynion (Image: Hynion)