Surveys to Begin Off California for First Floating Wind Farm

Site survey work is set to kick off this month for RWE’s Canopy Offshore Wind project which will be located approximately 20 miles off the coast of Humboldt Country in Northern California. The project will mark several firsts, including a milestone in the development of RWE’s first commercial-scale floating offshore wind farm and the beginning of work on the Pacific and off California after the first U.S. auction in 2022.

"Surveying is an important step on the path toward developing Canopy Offshore Wind,” said Sam Eaton, CEO of RWE Offshore Wind Holdings. Utilizing state-of-the-art technology, the project will gather data about the federal lease area and the area between the lease and shore in federal waters. The waters in the lease area reach over 2,300 feet deep.

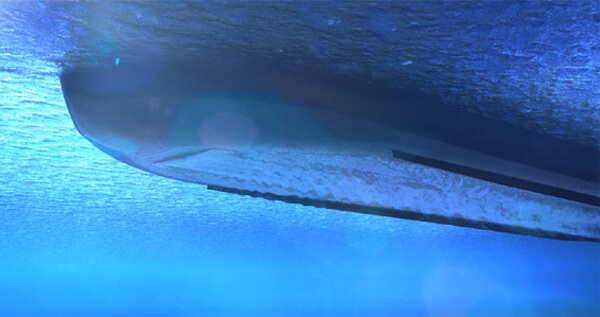

RWE has selected Argeo, a subsea service provider that has supported the development of clean energy projects around the world, to perform the site investigation work for Canopy. Due to the water depths in the lease area off the Pacific Coast of the U.S., Argeo will utilize an autonomous underwater vehicle (AUV) during this initial site characterization effort at the site. They highlight the system will enable high-quality data collection close to the seafloor, including photographs of biological communities.

"We will conduct subsea surveying utilizing proven, state-of-the-art technology," said Dave Gentle, Vice President for North and South America at Argeo. "With extensive experience in ocean surveying, Argeo is well-equipped to deliver comprehensive and detailed site information.”

They highlight that the AUV is battery-powered and can stay below the sea surface for extended periods. The use of AUVs as survey platforms will also significantly reduce the potential for entanglement of fishing gear as they are not towed equipment.

In compliance with U.S. permitting requirements and to ensure the project is developed in a responsible and safe manner, the survey work will also utilize certified, independent, Protected Species Observers on the survey vessels. Their role is to detect and avoid marine mammals during survey activities and to collect visual observation data on marine wildlife. RWE has selected Geo SubSea and Coastal 35 Consulting to provide PSOs on survey vessels.

Canopy plans to conduct initial site investigation surveys during 2024 and 2025, with the first activities beginning this month. By comprehensively mapping the seafloor, RWE says the project will begin to assess the best locations for installing wind turbines, anchors, and electric cables and better understand biodiversity, habitats, and other environmental factors to ensure responsible planning and design that minimizes the impact on ocean ecosystems.

RWE secured the right to develop an estimated 1.6 GW project in the 2022 federal offshore lease auction. Canopy Offshore Wind is expected to be in operation by the mid-2030s, contingent upon the permitting and regulatory timeline.

Tesla Battery Storage System to be Installed by Ørsted at UK Wind Farm

Ørsted has taken the final investment decision on a battery energy storage system which will be one of the largest so far deployed in Europe. It will be associated with the Hornsea 3 project which with an expected capacity of 2.9 GW is billed as the world’s single largest offshore wind farm.

The Tesla battery energy storage system will be installed on the same site as the onshore converter station for Ørsted’s Hornsea 3 Offshore Wind Farm in Swardeston, near Norwich, Norfolk, in the eastern part of England. According to the company, it will provide stability to the UK energy supply and reduce price volatility.

“The battery will help ensure that renewable energy is used in the best possible way by storing it when demand is lower and then releasing it back into the system when it’s really needed, thereby maximizing the potential of renewable energy whilst providing increased energy security and value to consumers,” said Duncan Clark, Head of UK & Ireland for Ørsted.

The storage system will have a capacity of 600 MWh (and a 300 MW power rating), equivalent to the daily energy use of 80,000 UK homes. When it is windy and sunny, so that electricity generation exceeds demand, the battery will store the excess so it can be discharged later to help balance the grid. The system is designed to reduce price volatility for consumers as it will make more power available, including during peak periods, when energy is traditionally more expensive. It will also result in UK energy systems being easier to manage by helping smooth out the variations between supply and demand.

With the battery energy storage system, Ørsted reports it is investing in a grid-balancing technology which is a natural add-on to its offshore wind power generation business and will provide complementary services and revenue profile while supporting the continued build-out of the UK’s renewable energy infrastructure.

Ørsted currently has a total of 660 MW (1,850 MWh) storage projects in operation or under construction in the UK and US including the project announced today. When complete, the battery energy storage system for Hornsea 3 will be one of the largest in Europe. It is expected to be operational by the end of 2026. In addition, Ørsted reports it is developing a storage opportunity pipeline of more than 2 GW across the UK, Ireland, and the U.S.

The company took the final investment decision (FID) for Hornsea 3 at the end of 2023. It will be Ørsted’s third gigawatt-scale project in the Hornsea zone following Hornsea 1 (1.2 GW) and Hornsea 2 (1.3 GW), which are already being operated out of Ørsted’s operations and maintenance hub in Grimsby.

Ørsted was awarded a contract for difference (CfD) for Hornsea 3 in July 2022. Hornsea 3 will be located about 100 miles off the Yorkshire coast and will employ Siemens Gamesa SG 14-236 DD offshore wind turbines, which have a capacity of 14 MW excluding power boost. The project will make up a more than 5 GW wind zone making it the world’s largest operating offshore wind zone. The Hornsea zone will also include Ørsted’s Hornsea 4 project, which could have a capacity of up to 2.6 GW.

World’s Largest Offshore Wind Turbines Begin Testing in China

Chinese manufacturers are pushing forward with their efforts to upsize turbines for offshore wind farms. Two of the largest turbines ever built, Envision Energy’s 16.7 MW prototype and Dongfang Electric’s 18 MW prototype, have both begun testing while even larger turbines are in the offing. The Chinese manufacturers are competing for the domestic market as well as looking to expand the international market for wind turbines.

Envision Energy, founded in 2007 in Shanghai, reports that it completed the first grid connection for its 16.7 MW turbine. This surpasses the 16 MW turbine launched by China’s Goldwind and installed offshore in Fujian Province in Southeast China. Last September, the 16 MW turbine claimed a new record reportedly producing 384.1 megawatt hours in 24 hours helped by the strong winds from an approaching typhoon. A month earlier, a Danish wind turbine set a record at 364 MWh. The Goldwin turbine covers a massive 826-foot (252-meter) diameter.

Envision reports its turbine was designed and built for the demanding conditions at deep water locations. In addition to reliability, the large turbine is designed to reduce construction costs requiring fewer turbines to achieve targeted power levels and low maintenance costs.

Last week, on June 5, Dongfang Electric however further pushed the limits of the field completing the installation of its 18 MW semi-direct dive turbine also designed for deep sea offshore installations. Manufacturing of the turbine was completed in April and it was shipped to a coastal test location in Guangdong Province in southeast China near Hong Kong.

The 18 MW turbine covers a diameter of 853 feet (260 meters). It uses a modular design and the shaft system, gearbox, and generator are integrated to improve reliability and efficiency. The company says the unit is capable of producing 72 million kWh per year. For maintenance, the unit has a lifting device.

Dongfang illustrates the rapid advancement in the field highlighting that it installed its first offshore wind turbine in 2013. It was a 5 MW unit and just six years later in 2019 they installed Asia’s first 10 MW unit. In 2022, they installed Asia’s first 13 MW unit, with the company claiming today that it accounts for more than a third of the Chinese market for turbines above 10 MW.

By comparison, GE Verona announced plans in March 2023 to upsize its Haliade-X turbine to reach between 17 and 18 MW. The company’s largest turbine is currently 14.7 MW. However, less than a year later, GE reported it was shelving plans for the big 18 MW turbine and instead would focus on the 15 MW which it called a “workhorse” for the industry. However, projects in New York State had been bid with the 18 MW turbines, and New York’s regulator NYSERDA in April 2024 ended its third-round solicitation without awarding any contracts saying the withdrawal of the larger turbines had “caused material changes to the proposed projects.”

Chinese manufacturers are continuing to push the envelope on the designs. Mingyang Wind Power last fall surprised the industry by announcing plans for a 22 MW turbine which they said they expect to complete between 2024 and 2025. The company already has its 16 MW turbine in production and is moving forward with an 18 MW design.

According to data from Wood Mackenzie, China now has four of the top five wind turbine manufacturers with Vestas being the only Western manufacturer in the top five. Worldwide, there was approximately 67.4 GW of offshore wind energy capacity installed as of the end of 2023, with China building a strong lead. As of the end of the year, China had more than 31 GW installed with the UK a distance second at just under 15 GW installed.

Damen Announces New Offshore Charging Solution for Fully Electric CTVs

[By: Damen Shipyards Group]

Damen Shipyards Group has developed a new concept for offshore charging, offering a way to dramatically reduce emissions during the operational phase of an offshore wind farm. The system envisages a fully electric crew transfer vessel (CTV) which can charge at either a turbine or one of Damen’s Commissioning Service Operations Vessels outfitted with a charger.

Enabling investment today in the solutions of tomorrow

With the infrastructure for turbine mounted chargers not yet widely available, vessel-to-vessel charging offers CTV owners and operators an opportunity to invest in the sustainable technology of the future, at the present time, as Mark Couwenberg Product Manager Service Operations Vessels at Damen explains.

“Offshore charging is an essential feature for a fully electric CTV operation. Typically, this would be dependent on charging infrastructure being present at an offshore wind farm. Our unique position as builders of both CTVs and CSOVs led us to the idea of placing the charging scope within our assets. This can be done with both a conventional, diesel-powered CSOV, or with a fully electric version. Of course, from an emissions reduction perspective, the latter is the more preferable option. However, such a solution makes it possible for CTV operators to invest today, in preparation for the wider distribution of full electric CSOVs tomorrow. We believe this could give a considerable boost to the maritime energy transition.”

Easy energy access

Installing a large battery system on board a CTV is a challenge, given the weight and space restrictions. Installing the system to the much larger, less space sensitive CSOV gives the smaller vessel access to the energy it requires without compromising on capabilities.

Using the CSOV as a charger host offers further advantages. For one thing, the stern of the vessel is lower than a turbine, which provides the vessel with easier access to the charger. Additionally, unlike the turbine, the CSOV is able to change its position, enabling the CTV to charge in the most sheltered position with regards to wave conditions.

The charging system that Damen has applied to its concept is developed by UK-based MJR, a specialist in offshore charging systems. The CTV would connect via a bell mouth that catches the charger that is lowered from a reel on the aft deck of the CSOV.

Following personnel disembarkation, the vessel could connect using a highly automated, safe process. It is expected that charging could take place in 2-3 hours, depending on the operational profile.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

MacGregor Secures Crane Order for MMA Offshore

[By: MacGregor]

MacGregor, part of Cargotec, has received a large order for its 50-tonne active heave compensated (AHC) crane to be installed on board MMA Valour, a versatile and ?exible multi-purpose platform supply vessel. The vessel has a proven track record in servicing a broad range of offshore work scopes across the energy and offshore wind sectors.

The contract has been booked into Cargotec’s second quarter 2024 order intake, with crane supply scheduled for the third quarter of 2025.

MacGregor’s range of well proven AHC cranes, including its subsea cranes, offer precise lifting capabilities in all conditions, including extreme environments and across temperatures of between plus to minus 40°C.

This contract follows successful deliveries of AHC cranes by MacGregor to MMA Offshore for two of its flagship vessels the MMA Pinnacle and MMA Prestige.

MMA Offshore Managing Director, David Ross said, “We are looking forward to fitting the MMA Valour with a MacGregor active heave compensated crane which will enhance the vessel’s capability to provide a broader range of marine and subsea services to our clients. The conversion of the Valour to a multi-purpose support vessel will enable the vessel to provide light construction, ROV, survey and geotechnical support in addition to traditional supply services. We are excited to partner with MacGregor for this important conversion.”

Senior Vice President, Offshore Solutions, MacGregor, Pasi Lehtonen said, “Our AHC cranes have a proven record for reliability, and we have extensive experience in supporting their operation with more than 250 units in service. MMA Offshore is a long-standing MacGregor customer, and we are delighted to add AHC lift capabilities as part of the Valour upgrade.”

The products and services herein described in this press release are not endorsed by The Maritime Executive

Damen Proposes Vessel-to-Vessel Charging for Offshore Wind Farm CTVs

One of the limitations of introducing fully electric Crew Transfer Vessels is the lack of charging options for the vessels while on-site at wind farms. While several technologies are being developed for charging buoys or connections to a wind turbine or substation, Damen Shipyards Group points out that the technologies, specifically turbine-mounted chargers, are not yet widely available.

With wind farms moving further offshore, charging will be required to use battery-powered transfer vessels or Commissioning Service Operations Vessels. Damen Shipyards Group developed a design for vessel-to-vessel charging which they believe offers operators a new option to incorporate electric vessels and reduce emissions at their wind farms.

Installing a large battery system on board a CTV Damen highlights is a challenge, given the weight and space restrictions. Installing the system to the much larger, less space-sensitive CSOV Damen says gives the smaller vessel access to the energy it requires without compromising on capabilities.

“Offshore charging is an essential feature for a fully electric CTV operation. Typically, this would be dependent on charging infrastructure being present at an offshore wind farm,” Mark Couwenberg Product Manager for Service Operations Vessels at Damen explains. “Our unique position as builders of both CTVs and CSOVs led us to the idea of placing the charging scope within our assets. This can be done with both a conventional, diesel-powered CSOV, or with a fully electric version.”

Following personnel disembarkation, the CTV would connect to the charger on the larger vessel using a highly automated process. It is expected that charging could take place in 2 to 3 hours, depending on the operational profile.

The charging system that Damen has applied to its concept is developed by UK-based MJR, a specialist in offshore charging systems. The CTV would connect via a bell mouth that catches the charger that is lowered from a reel on the aft deck of the CSOV.

They point to advantages of the vessel-to-vessel approach, including easier access to the stern of the CSOV versus the charging connection which is typically higher on the monopole of the wind turbine. The CSOV would also be able to reposition based on wave conditions, enabling the CTV to charge in a more sheltered location.

Damen designed an electric Fast Crew Supplier

Damen introduced the charging concept as it also unveiled designs for a larger, fully electric Fast Crew Supplier for crew transfers. It uses the Axe Bow hull shape with a rounded tunnel which they say reduces wet deck slamming and provides minimal resistance in the water. They increased the length of the vessel which provides space for a larger deckhouse and more deck capacity.

The design features a full electrical Volvo IPS system, enabling the CTV to sail exclusively on battery power. The vessel will be able to sail at high speeds to offshore wind farms up to 25 nautical miles from shore. On arrival, it will recharge at a charging system integrated into a turbine, substation, or SOV before returning to shore.

Purus has already ordered three diesel-electric versions from Damen. The company also reports that while methanol engine technology has not yet reached maturity for these vessels, it has developed designs for a methanol propulsion version. When the engines are ready, Damen notes its hybrid design is prepared for a fast conversion.