Oldendorff and MIT Find Fuel Degradation in Study of Advanced Biofuel

With an increasing exploration of biofuel across many sectors of the shipping industry and the emergence of new second-generation advanced biofuels, Oldendorff Carriers, one of the world’s leading dry bulk owners and operators, commissioned a study looking at the stability and potential for degradation of biofuel. Working with the Massachusetts Institute of Technology (MIT) they launched a study of the long-term stability of advanced biofuel (B20 blend) as a follow-on to a previous study of using biofuels to reduce emissions. They are now reporting that exposure to air, water, and light contributed significantly to fuel degradation in the advanced blends.

Results of the study were presented yesterday, November 6, at the American Institute of Chemical Engineers Annual Meeting. Oldendorff highlights in its summary of the results concerns identified regarding microbial contamination and oxidative degradation. The study looked at the fuels over a one-year timeframe and highlights steps to be taken as the use of the fuel expands to address the degradation as well as positive issues such as no sediment formation or water increase over time.

Oldendorff highlights that a biofuel blend is more complex than a homogenous product. Specifically, they point out as the industry moves to second-generation products that the presence of unsaturated fatty acids, which are inherent in the vegetable oils and animal fats from which the new biofuel is derived, is more prone to oxidative degradation. The concern is the potential for degradation of biofuel blends with conventional marine fuels over time when stored in vessels’ bunker tanks.

“There is a limited body of research on the degradation of biofuel blends, with existing studies primarily focusing on first-generation biofuels (derived from food crops) and/or distillate biofuel blends rather than advanced residual biofuel blends,” comments Oldendorff. The study with MIT sought to address this lack of information by monitoring eight chemical parameters over an extended period of time, under a variety of storage conditions and temperatures.

The Edwine Oldendorff was used for the study, a 38,600 dwt bulker built in 2016. The vessel was fueled in January 2022 with an advanced B20 biofuel, consisting of 20 percent bio-oil derived from used cooking oil and blended with very low sulfur fuel. Three storage groups were set up for the study using different containers and temperatures. The selected storage conditions closely replicate typical onboard fuel storage conditions and investigate the impact of storage temperature, air, light, and water on the fuel quality over time.

The findings show that fuel degradation was observed with levels of microbial contamination increasing over time. Emerging after the first month, the highest levels of contamination increased over time in samples exposed to light. Warning that microbial contamination could lead to operational problems, including fouling of tanks, pipes, and filters, tank corrosion, and fuel injection equipment damage, the report highly recommends a biocide addition to preserve blended biofuel for an extended period.

Similarly, oxidative degradation was observed starting between three and six months, with the report concluding that the addition of antioxidants is recommended. They are also calling for regular monitoring of fuel quality for long-term onboard storage, especially with higher biofuel blends. However, the study did not find sediment was generated after thermal aging, but says that the impact of storage temperature on degradation remains unclear.

“The results of our study will be valuable for both biofuel producers and users, assisting them in planning their bunker storage and maintenance systems accordingly over time,” concludes the team from MIT and Oldendorff.

Japan Conducts Test of Biofuel Using Non-Chemical Treated Vegetable Oil

Japan has conducted its first tests of a form of biofuel that further reduces emissions and will be less costly to supply to the maritime industry. The project is part of a government-sponsored effort testing different fuels to reduce emissions from the domestic shipping industry and mirrors similar test projects taking part in other parts of the world also looking at the viability of different forms of biofuel.

Until now, the main raw material for biofuels has been Fatty Acid Methyl Ester (FAME), which is produced by chemical processing of waste cooking oil and methanol. In this project, used cooking oil was mixed with heavy oil with a ratio of one-quarter of biomaterial. The bio component is in almost its original form, straight vegetable oil (SVO), as the component of the mix. Since the vegetable oil undergoes no methyl esterification or hydrogenation process, it is likely to reduce carbon dioxide (CO2) emissions more than other biofuels and can be supplied at a lower cost.

The fuel was supplied by Japan’s Hanwha Co. as part of the research project sponsored by Japan's Ministry of Land, Infrastructure, Transport and Tourism. It marked Japan's first initiative to use this kind of biofuel to power marine vessels.

The fuel was loaded on a small, general-purpose coastal vessel, the 499 gross ton Tetsuun Maru No.1, owned by Tetsuun Kisen KK. The vessel is operated by MOL Coastal Shipping, part of Mitsui O.S.K. Lines. The research program on the marine applications of biofuels was also conducted with the cooperation of Tokyo Steel Manufacturing Co., the cargo shipper.

The vessel operated on the biofuel mixture for about a month, plying a route between Mikawa Bay and Tokyo Bay. They are reporting that it was successfully operated using biofuel made by mixing waste cooking oil directly with heavy fuel oil. They reported no flammability problems or other issues.

The Ministry of Land, Infrastructure, Transport and Tourism highlights the significance of the test noting that vessels of 499 GT or less account for 62 percent of all the vessels of 100 or more gross tons in coastal operations in Japan.

This initiative on coastal vessels also followed a sea trial for the use of liquefied biomethane fuel conducted in June. In that test, a domestic LNG-fueled vessel, Ise Mirai (7,800 dwt) was tested using liquefied bio-methane (LBM). The fuel was derived from cattle manure resulting in a carbon-neutral LBM derived from biomass. The fuel was produced by the dairy industry which has biogas plants and experience using the carbon-neutral methane-based fuel.

Japan is continuing its research to identify viable carbon-neutral fuel sources for the maritime industry.

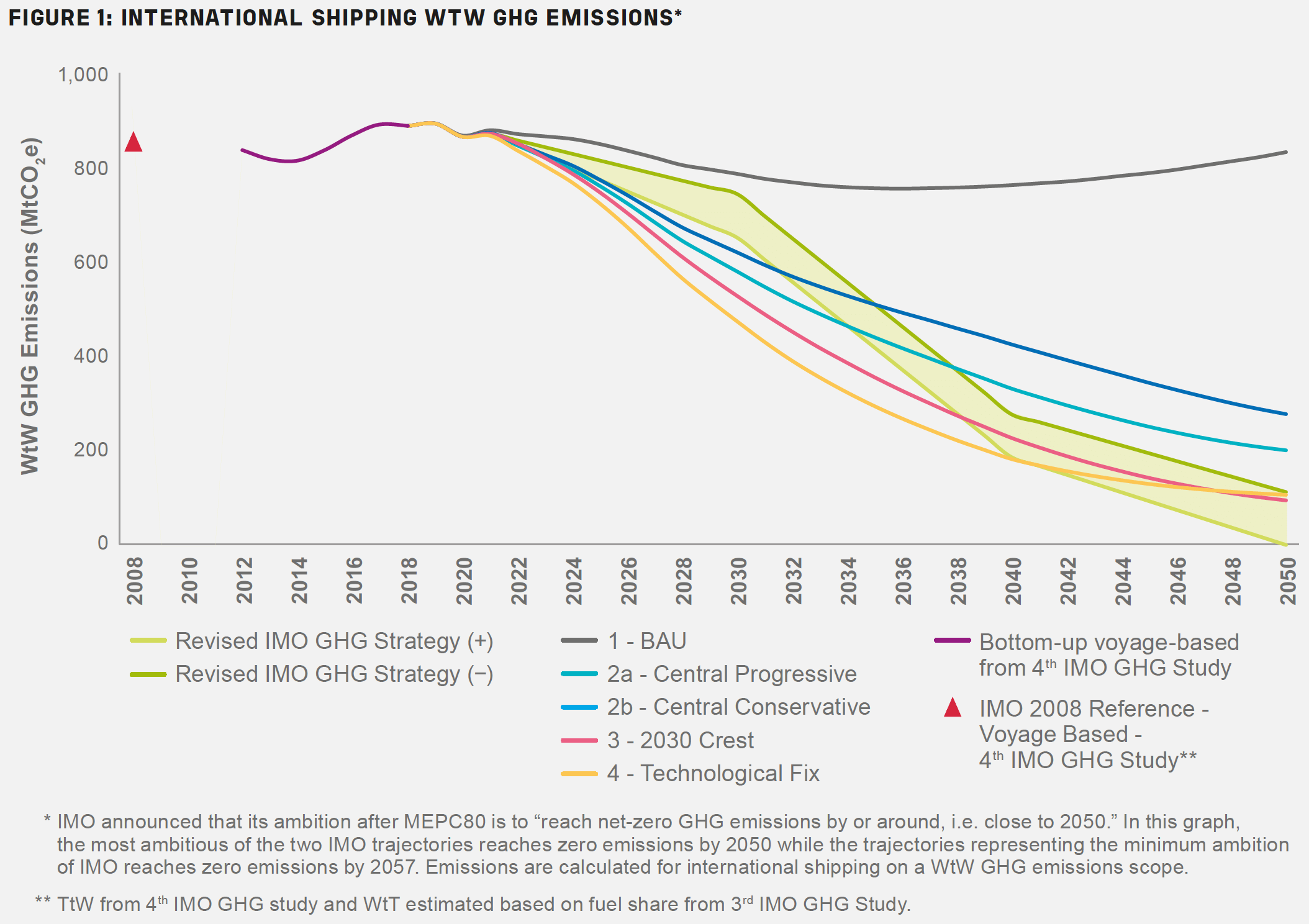

The maritime industry is facing an ever-tightening regulatory environment in its efforts to achieve its ambitious net-zero target by the middle of this century. For meaningful progress to be achieved, the industry needs two things: practical solutions, together with a detailed understanding of the actual impact of various long and short-term measures on the industry’s future decarbonization pathway.

The maritime industry is facing an ever-tightening regulatory environment in its efforts to achieve its ambitious net-zero target by the middle of this century. For meaningful progress to be achieved, the industry needs two things: practical solutions, together with a detailed understanding of the actual impact of various long and short-term measures on the industry’s future decarbonization pathway.