NUKE NEWZ

Danish university to create new nuclear research centre

18 January 2024

The Technical University of Denmark is establishing a new interdisciplinary centre that will consolidate and strengthen research in nuclear power technologies.

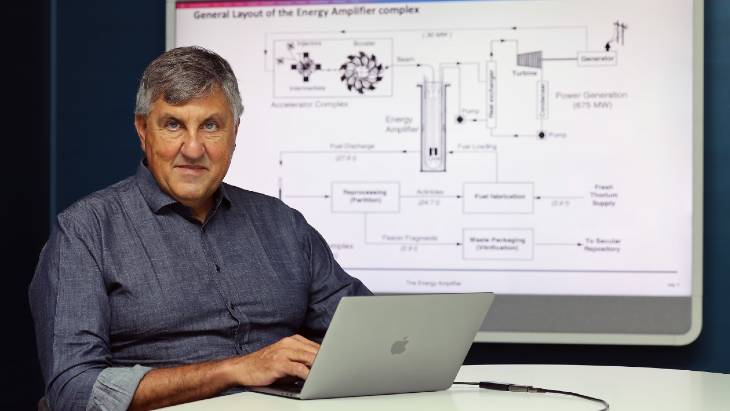

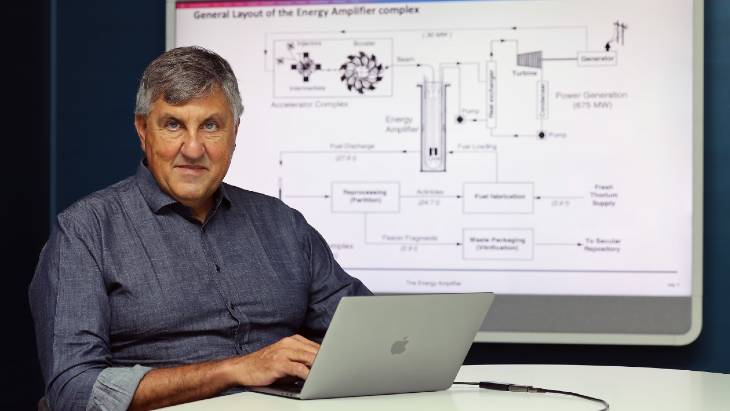

.jpg?ext=.jpg) Bent Lauritzen, who will head the DTU Nuclear Energy Technology (Image: Magnus Møller - DTU)

Bent Lauritzen, who will head the DTU Nuclear Energy Technology (Image: Magnus Møller - DTU)

Although research into nuclear power has been limited in Denmark over the past 40 years, The Technical University of Denmark (Danmarks Tekniske Universitet, DTU) has maintained several research environments that work with nuclear physics and nuclear technologies, thus maintaining professional expertise in the field.

Under the leadership of Bent Lauritzen, a senior researcher at DTU Physics, the new centre - to be named DTU Nuclear Energy Technology - will strengthen the collaboration between relevant research environments, currently located at the departments 0f DTU Physics, DTU Energy, DTU Chemistry and DTU Construct.

DTU Nuclear Energy Technology will ensure that Denmark continues to have strong competencies in the field and cooperate with Danish and international companies working to develop new reactor types, the university said.

The purpose of the new centre will be to: attract and support academic talent to strengthen research in nuclear energy technologies; expand capacities for teaching and supervision of students, including PhD students; create experimental facilities for such areas as characterisation of materials and simulation of new reactor technologies; and strengthen collaboration with Danish and international companies.

"The climate crisis has reached an extent that makes it crucial that we research all technologies that may be relevant in phasing out fossil energy sources," said DTU President Anders Bjarklev. "Regardless of whether nuclear power has a future in Denmark, it is important for DTU to have research in the field because we have an obligation to contribute research-based knowledge to society and our students. Our ambition with the creation of the new centre is to strengthen the part of the research that is specifically aimed at nuclear energy technologies."

DTU noted that the development of nuclear technologies has "advanced significantly", especially over the last 15 years or so. "In addition to the establishment of new, so-called Generation IV power plants as a further development of large, traditional nuclear power plants, work is being done to develop small, modular reactors," it said. "These differ from traditional plants both in terms of size, performance, and structure. A number of universities and companies worldwide - including two Danish startups - are working on developing and commercialising these small modular reactors."

"The technological breakthroughs that are happening in nuclear power these years are hugely interesting in terms of research," Lauritzen said. "New reactor technologies may well turn out to be able to contribute significantly to the world's energy supply, and this is what our research must help clarify. It is crucial that we, as a technical university, are ready to seize new technological opportunities when they arise."

Denmark had three nuclear research reactors, which started up between 1957 and 1960, at the Risø National Laboratory north of Roskilde on the island of Zeeland. DR-1, a 2kWt homogeneous unit from 1957, stopped operating in 2001 and was fully decommissioned in 2006. A 5 MWt pool reactor (DR-2) closed in 1975, and a 10 MWt heavy water reactor (DR-3) closed in 2000. Fuel fabrication facilities for DR-2 and DR-3 were closed in 2002.

The Risø National Laboratory was incorporated into DTU and is now known as the Risø National Laboratory for Sustainable Energy. Although fission research at Risø has stopped, nuclear research (including fusion) still continues and its Hevesy Laboratory houses a cyclotron, which is used for radioactive isotope production.

In 1985, the Danish parliament passed a resolution that nuclear power plants would not be built in the country and there is currently no move to reverse this situation.

Dutch initiative to boost nuclear workforce

17 January 2024

With the Netherlands planning an expansion of its use of nuclear energy, various parties in the Dutch nuclear and education sectors have signed a declaration of intent aimed at boosting vocational education in nuclear technology.

.jpg?ext=.jpg) Representatives from the various partners at the signing ceremony (Image: Vonk)

Representatives from the various partners at the signing ceremony (Image: Vonk)

Nuclear power currently has a small role in the Dutch electricity supply, with the 485 MWe (net) Borssele pressurised water reactor providing about 3% of total generation. The plant has been in operation since 1973 and is scheduled to close in 2033. Research is being conducted into keeping the reactor in operation for longer. At the end of 2022, the Dutch government announced the Borssele site as the preferred location for two new power reactors. In addition, the new PALLAS reactor for the production of medical isotopes is under construction.

"For the realisation of all these ambitions, the influx of employees with sufficient knowledge of the nuclear industry needs to be improved and increased," the partners said in a joint statement. "This requires strengthening the relationship between the nuclear sector and educational institutions, in which vocational education plays a crucial role."

A declaration of intent has now been signed by industry participants COVRA, EPZ, NRG-Pallas and Urenco and educational institutions Scalda, Horizon College/Regio College, Vonk, ROC van Twente and TU Delft.

The aim is to jointly develop a new nuclear curriculum in order to increase the interest of students for careers in the nuclear sector. The organisations will develop a multi-year plan for cooperation and will jointly explore funding opportunities.

"The collaborating partners will focus on new education packages in the field of nuclear technology and radiation protection, coordinated internship programmes and better career orientation to make students enthusiastic about a career in the nuclear sector," the partners said. "The initiators are of course open to expanding cooperation with other vocational institutions, companies and organisations."

NRG-Pallas and TU Delft are already cooperating on the Nuclear Academy programme, which is funded by the Ministry of Economic Affairs and Climate. The programme focuses on strengthening nuclear knowledge and skills in the Netherlands on various levels.

Newcleo consults NTS on transport of MOX

18 January 2024

UK-headquartered innovative reactor developer Newcleo has commissioned Nuclear Transport Solutions (NTS) to carry out feasibility studies in several areas of nuclear transport requirements, including for the transport of mixed plutonium-uranium oxide (MOX) fuel.

.jpg?ext=.jpg) A cutaway of Newcleo's TL-30 reactor design (Image: Newcleo)

A cutaway of Newcleo's TL-30 reactor design (Image: Newcleo)

As part of this work, NTS will support Newcleo through investigating packaging solutions for nuclear fuel; physical security for nuclear fuel; and transport routing and asset options.

Newcleo's proposed small modular lead-cooled fast reactors would use MOX fuel. Newcleo is planning a 30 MWe lead-cooled fast neutron test reactor in France in 2030, with a 200 MWe first-of-a-kind commercial unit planned for the UK in 2032.

In June 2022, Newcleo announced it had contracted France's Orano for feasibility studies on the establishment of a MOX production plant.

"I am delighted to embark on these studies with NTS, which will cover a range of nuclear materials that are part of the Newcleo fuel cycle, including MOX fuel," said Andrew Murdoch, Newcleo Managing Director, UK Operations. "Newcleo's MOX fuel manufacturing facilities will be located in France, and movement of MOX fuel to our reactor sites, including those in the UK, will need to be managed to the highest standards of safety and security in line with stringent regulation.

"We look forward to collaborating with NTS and benefitting from their significant expertise as we build a new competitive industrial standard for nuclear in the UK and beyond."

NTS - part of the UK's Nuclear Decommissioning Authority - oversees three specialist nuclear vessels, a fleet of over 100 locomotives, and a 700+ strong team. It operates Direct Rail Services and Pacific Nuclear Transport Limited, which deliver rail and shipping activities.

"Our work in undertaking a number of feasibility studies for Newcleo is a great example of NTS, as specialists in the transportation of nuclear fuel, using our expertise to advise external partners on how best to address their individual transport challenges," said NTS CEO Seth Kybird. "This collaboration will help to support the delivery of energy ambitions both within the UK and overseas."

UK invests in new neutron facility

17 January 2024

The UK's National Physical Laboratory (NPL) has announced plans for a new neutron measurement facility at its site in Teddington, south-west London. The new accelerator system will be six times as powerful as the one it is replacing.

.jpg?ext=.jpg) 3D render of the new 2 MV coaxial tandetron particle accelerator to be installed in NPL's neutron measurement facility (Image: NPL)

3D render of the new 2 MV coaxial tandetron particle accelerator to be installed in NPL's neutron measurement facility (Image: NPL)

NPL said the new facility "will play a critical role in the safe and secure operation and continued development of the UK's nuclear energy, defence and fusion research sectors". It will provide "all-important traceability in terms of established safety protocols and stringent regulatory compliance that ensures new-build reactors can help drive the rapid and safe expansion of nuclear power in the UK".

It noted that the new system allows the UK government to continue to "provide an enduring and resilient measurement infrastructure, ensuring that measurements can always be made in the UK with integrity and consistency", as set out in the government's 2022 UK Measurement Strategy for the National Measurement System.

The facility consists of a new particle accelerator and is one of only a few known facilities worldwide that offers precision traceable neutron standards.

The new accelerator system will be a 2.0 MV Coaxial VHC Tandetron manufactured by High Voltage Engineering Europa BV of the Netherlands, the same company that manufactured the current KN3000 Van de Graaff accelerator over 60 years ago.

NPL said the upgraded neutron facility addresses a number of current, future and emerging needs in the nuclear sector, including: the characterisation of new instrumentation and detectors required to ensure the UK's nuclear infrastructure and future reactors operate safely and efficiently; providing the expertise and facilities to enable the characterisation of neutron diagnostics, neutronics benchmark and validation experiments and nuclear cross section and decay-data measurement, to support the work at UK-based world-leading fusion research organisations and their supply chains; producing both monoenergetic and thermal neutron fields for UK Defence and Security; and the characterisation and calibration of new area survey instruments and personal dosemeter products to assure the safety of workers within the nuclear sector.

The upgrade has been funded by the former Department for Business for Energy and Industrial Strategy (BEIS) PSRE Infrastructure Fund.

"By extending the UK's capability in neutron standards and device calibration which leads to improved accuracy and direct measurement in place of extrapolated data and therefore helping to accelerate work on advanced nuclear technologies, we are ensuring the UK is leading in this field," said NPL CEO Peter Thompson.

"This is an exciting time for UK nuclear science and this facility is a concrete example of that," added Michael Bunce, Senior Scientist and Technical Lead at NPL. "With this machine we will be able to continue to provide standards to UK and international customers with greater efficiency and reliability whilst extending our research into new areas such as nuclear data measurements in support of fusion."

Last week, the British government launched a roadmap for reaching its ambition for the UK to have 24 GWe of nuclear generating capacity by 2050, representing about 25% of the country's projected electricity demand. The plans include next steps for exploring a large-scale nuclear power plant as well as small modular reactors. The roadmap also includes a government ambition to secure 3–7 GW worth of investment decisions every five years from 2030 to 2044 on new nuclear projects.

Nuclear Minister Andrew Bowie said: "We are reviving our nuclear industry to deliver net-zero and secure our energy independence, with plans to build new large and small-scale reactors. These upgrades to National Physical Laboratory's neutron facility will enable the safe and efficient operation of our new projects, as we ramp up clean and reliable nuclear power."

UEC to restart Wyoming uranium operation

17 January 2024

First uranium production at Christensen Ranch is expected in August after Uranium Energy Corp's (UEC) board of directors approved restarting the fully permitted and past-producing in-situ leach (ISL) operation - the output will be sold at prevailing spot market prices.

.jpg?ext=.jpg) Inside the Christensen Ranch satellite plant (Image: UEC)

Inside the Christensen Ranch satellite plant (Image: UEC)

Uranium recovered from Christensen Ranch will be processed at the fully operational Irigaray Central Processing Plant. Irigaray, with a licensed capacity of 2.5 million pounds U3O8 (962 tU) per year, is the hub at the centre of the company's Wyoming hub-and-spoke project which includes eleven satellite ISL projects, four of which are fully permitted.

First production will be funded with existing cash on the company's balance sheet and, in line with UEC's strategy to remain 100% unhedged, will be sold at prevailing spot market prices, the company said.

"This is the moment we have been working towards for over a decade," UEC President and CEO Amir Adnani said. "Uranium market fundamentals are the best the industry has witnessed, and various supply shocks have accelerated the bull market with recent prices eclipsing the USD100 per pound level. With this exciting backdrop, we are pleased to announce our production restart in Wyoming."

Initiatives to resume production are also being advanced at the company's South Texas hub-and-spoke platform, he added.

Extensive preparations, including the re-installation of equipment, re-attachment of piping and a variety of electrical testing, repairs and upgrades to the existing facilities, were completed at the Christensen Ranch wellfields and satellite processing plant last year. Work has also progressed on a detailed wellfield startup plan, drilling to identify additional resources, and submittal of an application to the Wyoming Department of Environmental Quality to expand the Irigaray processing plant's licensed capacity to 4 million pounds U3O8 per year.

UEC took ownership of Irigaray and the orebodies in the Wyoming hub-and-spoke operation, including Christensen Ranch, through its 2021 acquisition of Uranium One Americas Inc from Russian state nuclear corporation Rosatom. According to information from the US Energy Information Administration, Christensen Ranch and the Irigaray plant - together known as the Willow Creek project - have been on standby since last operating in 2018.

Operations will initially resume at mine units 7, 8 and 10, UEC said. The company will "in the coming months" provide further information on expected volumes for the first year of production, but is currently focused on the hiring and training of additional operations personnel to augment the company's existing team. It anticipates that new hires will be from local communities.

UEC's Wyoming projects contain total measured and indicated uranium resources of 66.198 million pounds U3O8, with total inferred resources of 15.54 million pounds.

First lead-cooled fast neutron reactor's installation under way

17 January 2024

A steel reactor base plate and the lower tier of the containment has been installed in what is being called a landmark moment for construction of the BREST-OD-300 generation IV fast neutron reactor in Russia.

(Image: Rosatom)

(Image: Rosatom)

The reactor base plate, weighing 165 tonnes, was delivered to the site in two pieces in September 2022 and has been assembled on site. It is designed to equalise the loads on the foundation from the elements of the reactor vessel. The pouring of concrete for the foundation slab was completed in August 2021. The first part of the reactor vessel, the lower tier of the containment, has also been loaded into the reactor shaft.

The lead-cooled BREST-OD-300 fast reactor is part of Rosatom's Proryv, or Breakthrough, project to enable a closed nuclear fuel cycle. The 300 MWe unit will be the main facility of the Pilot Demonstration Energy Complex at the Siberian Chemical Combine site. The complex will demonstrate an on-site closed nuclear fuel cycle with a facility for the fabrication/re-fabrication of mixed uranium-plutonium nitride nuclear fuel, as well as a used fuel reprocessing facility.

A fuel production facility and an irradiated fuel reprocessing module are scheduled to be built by 2023 and 2024, respectively, while the BREST-OD-300 reactor is expected to start operation in 2026.

Vadim Lemekhov, chief designer of the BREST-OD-300 reactor unit and the project team, said: "We have started installation of the world’s first lead-cooled fast reactor, the fourth generation reactor BREST-OD-300. Unlike traditional light-water VVER thermal reactors, BREST has an integral layout. Its vessel is not an all-metal structure like the VVER, but a metal-concrete structure with metal cavities to accommodate the primary circuit equipment. The space between the cavities should be gradually filled with concrete filler during construction. In addition, the BREST vessel is larger in size, it can be delivered only in parts, and the final assembly is possible only at the construction site."

Fast reactors such as BREST-OD-300 are able to use secondary products from the traditional reactors' fuel cycle, such as plutonium, for their own fuel, as well as being to produce more potential fuel than they consume. The reactor will provide itself with its main energy component - plutonium-239 - by reproducing it from the isotope uranium-238, Russia's fuel company, TVEL, says. As about 99% of natural uranium is uranium-238, Rosatom says "the introduction of such technologies will increase exponentially the efficiency of natural uranium".

According to the World Nuclear Association information paper on fast neutron reactors, "the BREST fast neutron reactor, of 700 MWt, 300 MWe has lead as the primary coolant, at 540°C, and supercritical steam generators. It is inherently safe and uses a mixed uranium and plutonium nitride fuel... no weapons-grade plutonium can be produced, since there is no uranium blanket - all the breeding occurs in the core ... fuel cycle is quoted at 5-6 years with partial refuelling at about 10 months. The initial cores can comprise plutonium and spent fuel - hence loaded with fission products, and radiologically 'hot'. Subsequently, any surplus plutonium, which is not in pure form, can be used as the cores of new reactors. Used fuel can be recycled indefinitely, with onsite facilities. The nitride fuel has been successfully tested in the BN-600 reactor to a burn-up of 7.4%".

Initial operation of the demonstration unit will be focused on performance and after 10 years or so it will be commercially oriented. The plan has been that if it is successful as a 300 MWe unit, a 1200 MWe (2800 MWt) version will follow - the BR-1200.

Nuclear battery: Chinese firm aiming for mass market production

16 January 2024

Beijing Betavolt New Energy Technology Company Ltd claims to have developed a miniature atomic energy battery that can generate electricity stably and autonomously for 50 years without the need for charging or maintenance. It said the battery is currently in the pilot stage and will be put into mass production on the market.

.jpg?ext=.jpg) The BV100 battery (Image: Betavolt)

The BV100 battery (Image: Betavolt)

Atomic energy batteries - also known as nuclear batteries or radioisotope batteries - work on the principle of utilising the energy released by the decay of nuclear isotopes and converting it into electrical energy through semiconductor converters.

Betavolt, which was established in April 2021, says its battery "combines nickel-63 nuclear isotope decay technology and China's first diamond semiconductor (4th generation semiconductor) module to successfully realise the miniaturisation of atomic energy batteries".

The company's team of scientists developed a unique single-crystal diamond semiconductor that is just 10 microns thick, placing a 2-micron-thick nickel-63 sheet between two diamond semiconductor converters. The decay energy of the radioactive source is converted into an electrical current, forming an independent unit. Betavolt said its nuclear batteries are modular and can be composed of dozens or hundreds of independent unit modules and can be used in series and parallel, so battery products of different sizes and capacities can be manufactured.

.jpg)

The composition of a nuclear battery (Image: Betavolt)

Betavolt says its batteries can meet the needs of long-lasting power supply in multiple scenarios such as aerospace, AI equipment, medical equipment, micro-electromechanical systems, advanced sensors, small drones and micro-robots. "If policies allow, atomic energy batteries can allow a mobile phone to never be charged, and drones that can only fly for 15 minutes can fly continuously," it said.

The first battery that the company plans to launch is the BV100, which it claims will be the world's first nuclear battery to be mass-produced. Measuring 15mm by 15mm and 5 mm thick, the battery can generate 100 microwatts, with a voltage of 3V. The company plans to launch a 1-watt battery in 2025.

Betavolt says its atomic energy battery is "absolutely safe, has no external radiation, and is suitable for use in medical devices such as pacemakers, artificial hearts, and cochleas in the human body". It adds: "Atomic energy batteries are environmentally friendly. After the decay period, the nickel-63 isotope as the radioactive source turns into a stable isotope of copper, which is non-radioactive and does not pose any threat or pollution to the environment."

The company plans to continue research on using isotopes such as strontium-90, promethium-147 and deuterium to develop atomic energy batteries with higher power and a service life of 2-30 years.

Lotus eyes 2025 for Kayelekera restart

16 January 2024

Lotus Resources has entered the final phase of planning to restart the Kayelekera uranium mine in Malawi in late 2025. The Australian company is also working to optimise resources at Letlhakane in Botswana, with a resource update planned for the first half of this year.

_1.jpg?ext=.jpg) Kayelekera (Image: Lotus)

Kayelekera (Image: Lotus)

Managing Director Keith Bowes said the company is focused on restarting Kayelekera "as soon as practicable" to benefit from "strong and increasing" uranium prices. "As such, Lotus is testing the market for debt and is focused on undertaking the necessary planned activities to prepare Kayelekera for a potential restart of production in late 2025 when the supply gap for the nuclear utilities is forecast," he said.

This target date will depend on a number of conditions being met and the successful conclusion of various actions before or as part of a final investment decision (FID), the company said. These include: finalising financing and offtake for the project; signing a power supply and power implementation agreement with Malawian electricity utility ESCOM; a front-end engineering and design programme leading directly into the detailed engineering design phase for the execution of the restart plan, which will amongst other things enable a budget to be prepared for the restart and validate timelines; and the completion of negotiations on a mine development agreement and associated fiscal regime with the Government of Malawi.

These workstreams have been prioritised so that an FID can be made as soon as possible, the company said.

Kayelekera, which is 85% owned by Lotus, has a current resource of 51.1 million pounds U3O8 (19,655 tU). The project, which Lotus acquired from Paladin Energy in 2020, produced around 11 million pounds U3O8 between 2009 and 2014, when it was placed on care and maintenance.

Letlhakane update

Work at Letlhakane - acquired through Lotus's 2023 merger with A-Cap Energy - will aim to determine if a more effective processing route can be identified to improve the project economics of the 2015 feasibility study, which had envisaged a heap leach process. This will include updating the Letlhakane mineral resource model and undertaking preliminary test work to determine the potential of upgrading Letlhakane ore, Bowes said.

"While Letlhakane is considered the longer term asset, Lotus remains focused on restarting the Kayelekera Project as soon as practicable to benefit from the current strong and increasing uranium prices. As such, Lotus is testing the market for debt and is focused on undertaking the necessary planned activities to prepare Kayelekera for a potential restart of production in late 2025 when the supply gap for the nuclear utilities is forecast," he added.

Newcleo and Naarea launch Gen-IV partnership

16 January 2024

France's Naarea and the UK-headquartered Newcleo have announced a strategic and industrial partnership designed "to support all players in their industrial, technological, scientific and regulatory development" of Generation IV fast neutron reactors.

Newcleo's chairman and CEO (Image: Newcleo)

Newcleo's chairman and CEO (Image: Newcleo)

The companies say that the partnership will be open to others to join and said it will focus on key areas where there are common interests, such as gaining access to the used nuclear fuel from conventional nuclear reactors that their Gen-IV reactors are designed to use as part of their efforts to close the fuel cycle.

Other areas of cooperation are the development of a joint research and development platform for areas such as heat exchangers and materials, and working together to unlock financing and funding for both the research and for the fuel cycle infrastructure that will be required.

They also propose to cooperate on the industrial development front with regulators and on "providing access to scientific computing tools particularly for safety demonstrations, making test centre sites available for future prototypes and developing and implementing shared test facilities".

Newcleo is planning a 30 MWe lead-cooled fast neutron test reactor in France in 2030, with a 200 MWe first-of-a-kind commercial unit planned for the UK in 2032. Naarea is developing a 40 MWe/80 MWt molten salt fast neutron reactor with a target of 2027 for a prototype and by 2030 for construction of a manufacturing facility and launch of series production.

Stefano Buono, Newcleo chairman and CEO, said that by joining forces the two companies were "further encouraging the development and deployment of Gen-IV nuclear technology in Europe. This collaboration reinforces our shared commitment to innovation and sustainability in the nuclear sector".

Jean-Luc Alexandre, chairman and founder of Naarea, said the two firms were "creating momentum to accelerate their development by providing a joint and coordinated response to the demands of public authorities for a unified voice to express common needs. Our two companies want to simplify the work of public authorities and ultimately promote the development and deployment of Gen-IV nuclear power in Europe, against a backdrop of strong global competition".

Researched and written by World Nuclear News

.jpg?ext=.jpg) Bent Lauritzen, who will head the DTU Nuclear Energy Technology (Image: Magnus Møller - DTU)

Bent Lauritzen, who will head the DTU Nuclear Energy Technology (Image: Magnus Møller - DTU).jpg?ext=.jpg) Representatives from the various partners at the signing ceremony (Image: Vonk)

Representatives from the various partners at the signing ceremony (Image: Vonk).jpg?ext=.jpg) A cutaway of Newcleo's TL-30 reactor design (Image: Newcleo)

A cutaway of Newcleo's TL-30 reactor design (Image: Newcleo).jpg?ext=.jpg) 3D render of the new 2 MV coaxial tandetron particle accelerator to be installed in NPL's neutron measurement facility (Image: NPL)

3D render of the new 2 MV coaxial tandetron particle accelerator to be installed in NPL's neutron measurement facility (Image: NPL).jpg?ext=.jpg) Inside the Christensen Ranch satellite plant (Image: UEC)

Inside the Christensen Ranch satellite plant (Image: UEC) (Image: Rosatom)

(Image: Rosatom).jpg?ext=.jpg) The BV100 battery (Image: Betavolt)

The BV100 battery (Image: Betavolt).jpg)

_1.jpg?ext=.jpg) Kayelekera (Image: Lotus)

Kayelekera (Image: Lotus) Newcleo's chairman and CEO (Image: Newcleo)

Newcleo's chairman and CEO (Image: Newcleo)