Green Hydrogen might be the fuel of the future

Image: REUTERS/ Jane Barlow

21 Dec 2021

Abhinav Chugh

The world's progress on transitioning to sustainable energy has stalled. Here’s how to fix it.

Read more about this project

Explore context

Hydrogen

Explore the latest strategic trends, research and analysis

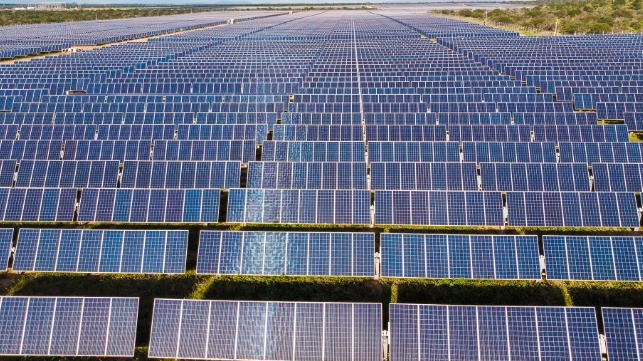

Green hydrogen could be a critical enabler of the global transition to sustainable energy and net zero emissions economies.

There is unprecedented momentum around the world to fulfil hydrogen’s longstanding potential as a clean energy solution.

Dr Emanuele Taibi lays out where things with hydrogen stand now and how it can help to achieve a clean, secure and affordable energy future.

The time is right to tap into hydrogen’s potential to play a key role in tackling critical energy challenges. The recent successes of renewable energy technologies and electric vehicles have shown that policy and technology innovation have the power to build global clean energy industries.

Hydrogen is emerging as one of the leading options for storing energy from renewables with hydrogen-based fuels potentially transporting energy from renewables over long distances – from regions with abundant energy resources, to energy-hungry areas thousands of kilometers away.

Green hydrogen featured in a number of emissions reduction pledges at the UN Climate Conference, COP26, as a means to decarbonize heavy industry, long haul freight, shipping, and aviation. Governments and industry have both acknowledged hydrogen as an important pillar of a net zero economy.

The Green Hydrogen Catapult, a United Nations initiative to bring down the cost of green hydrogen announced that it is almost doubling its goal for green electrolysers from 25 gigawatts set last year, to 45 gigawatts by 2027. The European Commission has adopted a set of legislative proposals to decarbonize the EU gas market by facilitating the uptake of renewable and low carbon gases, including hydrogen, and to ensure energy security for all citizens in Europe. The United Arab Emirates is also raising ambition, with the country’s new hydrogen strategy aiming to hold a fourth of the global low-carbon hydrogen market by 2030 and Japan recently announced it will invest $3.4 billion from its green innovation fund to accelerate research and development and promotion of hydrogen use over the next 10 years.

You might encounter the terms ‘grey’, ‘blue’, ‘green’ being associated when describing hydrogen technologies. It all comes down to the way it is produced. Hydrogen emits only water when burned but creating it can be carbon intensive. Depending on production methods, hydrogen can be grey, blue or green – and sometimes even pink, yellow or turquoise. However, green hydrogen is the only type produced in a climate-neutral manner making it critical to reach net zero by 2050.

We asked Dr Emanuele Taibi, Head of the Power Sector Transformation Strategies, International Renewable Energy Agency (IRENA) to explain what green hydrogen is and how it could pave the way towards net zero emissions. He is currently based with the IRENA Innovation and Technology Center in Bonn, Germany, where he is responsible for assisting Member Countries in devising strategies for the transformation of the power sector, and currently managing the work on power system flexibility, hydrogen and storage as key enablers for the energy transition. Dr Taibi is also a co curator for the World Economic Forum’s Strategic Intelligence platform, where his team developed the transformation map on Hydrogen.

Green hydrogen technologies

What motivated you to develop your expertise in energy technologies and how does your work at IRENA contribute to it?

It was during my Master’s thesis. I did an internship in the Italian National Agency for Energy and Environment (ENEA), where I learnt about sustainable development and energy, and the nexus between the two. I wrote my thesis in management engineering about it and decided this was the area where I wanted to focus my working life. Fast forward almost 20 years of experience in energy and international cooperation, a PhD in Energy Technology and time spent in private sector, research and intergovernmental agencies, I currently lead the power sector transformation team at IRENA since 2017.

My work at IRENA is to contribute, with my team and in close cooperation with colleagues across the agency and external partners such as the World Economic Forum, in supporting our 166 Member Countries in the energy transition, with a focus on renewable electricity supply and its use to decarbonize the energy sector through green electrons as well as green molecules like hydrogen and its derivatives.

What is green hydrogen? How does it differ from traditional emissions-intensive ‘grey’ hydrogen and blue hydrogen?

Hydrogen is the simplest and smallest element in the periodic table. No matter how it is produced, it ends up with the same carbon-free molecule. However, the pathways to produce it are very diverse, and so are the emissions of greenhouse gases like carbon dioxide (CO2) and methane (CH4).

Green hydrogen is defined as hydrogen produced by splitting water into hydrogen and oxygen using renewable electricity. This is a very different pathway compared to both grey and blue.

Grey hydrogen is traditionally produced from methane (CH4), split with steam into CO2 – the main culprit for climate change – and H2, hydrogen. Grey hydrogen has increasingly been produced also from coal, with significantly higher CO2 emissions per unit of hydrogen produced, so much that is often called brown or black hydrogen instead of grey. It is produced at industrial scale today, with associated emissions comparable to the combined emissions of UK and Indonesia. It has no energy transition value, quite the opposite.

Blue hydrogen follows the same process as grey, with the additional technologies necessary to capture the CO2 produced when hydrogen is split from methane (or from coal) and store it for long term. It is not one colour but rather a very broad gradation, as not 100% of the CO2 produced can be captured, and not all means of storing it are equally effective in the long term. The main point is that capturing large part of the CO2, the climate impact of hydrogen production can be reduced significantly.

Depending on production methods, hydrogen can be grey, blue or green – and sometimes even pink, yellow or turquoise

Image: International Renewable Energy Agency

There are technologies (i.e. methane pyrolysis) that hold a promise for high capture rates (90-95%) and effective longterm storage of the CO2 in solid form, potentially so much better than blue that they deserve their own colour in the “hydrogen taxonomy rainbow”, turquoise hydrogen. However, methane pyrolysis is still at pilot stage, while green hydrogen is rapidly scaling up based on two key technologies - renewable power (in particular from solar PV and wind, but not only) and electrolysis.

Unlike renewable power, which is the cheapest source of electricity in most countries and region today, electrolysis for green hydrogen production needs to significantly scale-up and reduce its cost by at least three times over the next decade or two. However, unlike CCS and methane pyrolysis, electrolysis is commercially available today and can be procured from multiple international suppliers right now.

Green hydrogen energy solutions

What are the merits of energy transition solutions towards a ‘green’ hydrogen economy? How could we transition to a green hydrogen economy from where we are currently with grey hydrogen?

Green hydrogen is an important piece of the energy transition. It is not the next immediate step, as we first need to further accelerate the deployment of renewable electricity to decarbonize existing power systems, accelerate electrification of the energy sector to leverage low-cost renewable electricity, before finally decarbonize sectors that are difficult to electrify – like heavy industry, shipping and aviation – through green hydrogen.

It is important to note that today we produce significant amount of grey hydrogen, with high CO2 (and methane) emissions: priority would be to start decarbonizing existing hydrogen demand, for example by replacing ammonia from natural gas with green ammonia.

Recent studies have sparked a debate about the concept of blue hydrogen as a transition fuel till green hydrogen becomes cost-competitive. How would green hydrogen become cost competitive vis-à-vis blue hydrogen? What sort of strategic investments need to occur in the technology development process?

The first step is to provide a signal for blue hydrogen to replace grey, as without a price for emitting CO2, there is no business case for companies to invest in complex and costly carbon capture system (CCS) and geological storages of CO2. Once the framework is such that low-carbon hydrogen (blue, green, turquoise) is competitive with grey hydrogen, then the question becomes: should we invest in CCS if the risk is to have stranded assets, and how soon will green become cheaper than blue.

The answer will of course differ depending on the region. In a net zero world, an objective that more and more countries are committing to, the remaining emissions from blue hydrogen would have to be offset with negative emissions. This will come at a cost. In parallel, gas prices have been very volatile lately, leaving blue hydrogen price highly correlated to gas price, and exposed not only to CO2 price uncertainty, but also to natural gas price volatility.

For green hydrogen, however, we might witness a similar story to that of solar PV. It is capital intensive, therefore we need to reduce investment cost as well as the cost of investment, through scaling up manufacturing of renewable technologies and electrolysers, while creating a low-risk offtake to reduce the cost of capital for green hydrogen investments. This will lead to a stable, decreasing cost of green hydrogen, as opposed to a volatile and potentially increasing cost of blue hydrogen.

Renewable energy technologies reached a level of maturity already today that allows competitive renewable electricity generation all around the world, a prerequisite for competitive green hydrogen production. Electrolysers though are still deployed at very small scale, needing a scale up of three orders of magnitude in the next three decades to reduce their cost threefold.

Today the pipeline for green hydrogen projects is on track for a halving of electrolyser cost before 2030. This, combined with large projects located where the best renewable resources are, can lead to competitive green hydrogen to be available at scale in the next 5-10 years. This does not leave much time for blue hydrogen – still at pilot stage today – to scale up from pilot to commercial scale, deploy complex projects (e.g. the longterm geological CO2 storage) at commercial scale and competitive cost, and recover the investments made in the next 10-15 years.

Several governments have now included hydrogen fuel technologies in their national strategies. Given the rising demands to transition towards decarbonization of the economy and enabling technologies with higher carbon capture rates, what would be your advice to policymakers and decisionmakers who are evaluating the pros and cons of green hydrogen?

We will need green hydrogen to reach net zero emissions, in particular for industry, shipping and aviation. However, what we need most urgently is:

1) energy efficiency;

2) electrification;

3) accelerated growth of renewable power generation.

Once this is achieved, we are left with ca. 40% of demand to be decarbonised, and this is where we need green hydrogen, modern bioenergy and direct use of renewables. Once we further scale up renewable power to decarbonise electricity, we will be in a position to further expand renewable power capacity to produce competitive green hydrogen and decarbonise hard-to-abate sectors at minimal extra cost.

How green hydrogen can be produced, converted and used across the energy system.

Image: International Renewable Energy Agency

The future of green hydrogen

Where do you see energy technologies relating to hydrogen evolving by 2030? Could we anticipate hydrogen-powered commercial vehicles?

We see the opportunity for rapid uptake of green hydrogen in the next decade where hydrogen demand already exists: decarbonising ammonia, iron and other existing commodities. Many industrial processes that use hydrogen can replace grey with green or blue, provided CO2 is adequately priced or other mechanisms for the decarbonisation of those sectors are put in place.

For shipping and aviation, the situation is slightly different. Drop-in fuels, based on green hydrogen but essentially identical to jet fuel and methanol produced from oil, can be used in existing planes and ships, with minimal to no adjustments. However, those fuels contain CO2, which has to be captured from somewhere and added to the hydrogen, to be released again during combustion: this reduces but does not solve the problem of CO2 emissions. Synthetic fuels can be deployed before 2030, if the right incentives are in place to justify the extra cost of reduced (not eliminated) emissions.

In the coming years, ships can switch to green ammonia, a fuel produced from green hydrogen and nitrogen from the air, which does not contain CO2, but investments will be needed to replace engines and tanks, and green ammonia is currently much more expensive than fuel oil.

Hydrogen (or ammonia) planes are further away, and these will be essentially new planes that have to be designed, built and sold to airlines to replace existing jet-fuel-powered planes – clearly not feasible by 2030: in this sense, green jet fuel – produced with a combination of green hydrogen and sustainable bioenergy – is a solutions that can be deployed in the near term.

In conclusion, the main actions to accelerate decarbonisation between now and 2030 are 1) energy efficiency 2) electrification with renewables 3) rapid acceleration of renewable power generation (which will further reduce the already low cost of renewable electricity) 4) scale up of sustainable, modern bioenergy, needed - among others - to produce green fuels that require CO2 5) decarbonisation of grey hydrogen with green hydrogen, which would bring scale and reduce the cost of electrolysis, making green hydrogen competitive and ready for a further scale up in the 2030s, towards the objective of reaching net zero emissions by 2050.

The World Economic Forum is a longstanding supporter of the clean hydrogen agenda since 2017, having helped -inter alia- with the creation of the Hydrogen Council, the establishment of a hydrogen Innovation Challenge in partnership with Mission Innovation, and the creation, together with the Energy Transitions Commission, of the Mission Possible platform to help transition hard-to-abate sectors to net zero emissions by 2050. Read more on the Accelerating Clean Hydrogen Initiative here.

Share

License and Republishing

Written by

Abhinav Chugh, Acting Content and Partnerships Lead, World Economic Forum

Emanuele Taibi, Head of the Power Sector Transformation Strategies, International Renewable Energy Agency

The views expressed in this article are those of the author alone and not the World Economic Forum.

CleanTechnica

~0.03% Of Hydrogen Is Green Hydrogen

CLEAN POWER

By Zachary Shahan

Published3 days ago

It seems that 95% of headlines and stories about hydrogen focus on green hydrogen, yet green hydrogen is barely present here on planet Earth. So, how much of a disservice is being done to society by all of these headlines and articles implying that hydrogen is clean?

When Mike Barnard interviewed Paul Martin for CleanTech Talk a few months ago, one stat caught my attention above all else — that 0.1% of global hydrogen production came from “green hydrogen” (hydrogen produced by splitting water using electricity produced by clean, renewable power). The focus of their discussion was the “Hydrogen Ladder.” (Read about part one and part two for more commentary, or listen to the podcasts — embedded below.)

While I knew that “green hydrogen” was mostly hype, small science projects, and a dream for the future, I didn’t realize it was just 0.1% of global hydrogen production. That stunningly low figure makes the hydrogen hype all the more irritating. You can listen to the full, super informative interview here:

Looking around the internet (thanks, Google), I couldn’t find much reference to this figure of 0.1% (or actually less than 0.1%) of global hydrogen production being green hydrogen production (ugh, Google). I did find a CNBC article from a year ago citing an International Energy Agency (IEA) report and saying, “less than 0.1% of hydrogen today is produced through water electrolysis.” That led me to this report from June 2019. It stated, “While less than 0.1% of global dedicated hydrogen production today comes from water electrolysis, with declining costs for renewable electricity, in particular from solar PV and wind, there is growing interest in electrolytic hydrogen.” Ah, yes, interest.

Luckily, Google did swiftly show me that there’s an updated report published in October 2021 and revised in November 2021, Global Hydrogen Review 2021. So, with all of this interest in green hydrogen in the past few years, where are we at?

The new report indicates that “water electrolysis made up ~0.03%” of global hydrogen production last year. That’s right — not even 0.3%, but a lowly 0.03%! It doesn’t show up on a pie chart of hydrogen sources, of course. (See image at top.) Nonetheless, headline after headline is about “green hydrogen.” Is the hype around green hydrogen doing more damage than good, or is it spurring on a yet-to-sprout green industry?

If you want to count carbon capture, utilization, and storage (CCUS), it provided another 0.7% of global hydrogen supply in 2020. However, that’s from 16 fossil fuel plants, and the CCUS components of the plants are surely heavily subsidized and are quite expensive methods of getting hydrogen. Many experts argue this can never be cost-competitive.

At the end of the day, the following chart shows three things: “green hydrogen” expectations from projects under construction or planned, the amount of it that is in country pledges by 2030, and the amount needed for an IEA net zero emissions scenario.

As it stands, despite all of the hype, the green hydrogen market is looking a bit anemic, and the 2030 projections based on plans or even pledges are not where the world needs it to be. Green hydrogen proponents will say that means that more money needs to be tossed at green hydrogen. Critics will say that we are throwing our money away on many of these green hydrogen projects and programs, money that could be used to fund more capital-efficient decarbonization tech.

The two bottom lines of this matter, in my opinion, are: 1) any funding for green hydrogen needs to be focused on solutions that have a serious chance at becoming cost competitive and thus truly useful in the effort to decarbonize, and 2) any coverage of green hydrogen needs to put this industry in context, should explain where 99.97% of hydrogen comes from, and should at least bring to mind why it is that fossil fuel companies are so keen on hyping the green hydrogen dream.

CleanTechnica.com

https://arab.news/nqvz4

Updated 25 December 2021

ARAB NEWS

RIYADH: Namibia is one of many countries seeking to cash in on the green energy rush and it is positioning itself as a leader in the emerging market for green hydrogen, The Wall Street Journal reported.

Many experts agree that “green” hydrogen, a carbon-friendly nontoxic gas produced using renewable energy, can play a significant role in achieving a green gas-neutral economy by 2050, helping to combat global warming.

The southwest African nation is already “putting up to €40 million ($45.3 million) from Germany to use on on feasibility studies and pilot projects related to so-called green hydrogen.”

“Germany’s government says Namibia’s natural advantages could help it produce the world’s cheapest green hydrogen — a crucial ingredient in policies hoping to cut carbon emissions to the net-zero benchmark by 2050,” the WSJ reported.

“The list is quite short of those new potential large renewable capable countries and Namibia is there,” the reported quoted Noel Tomnay, global head of hydrogen consulting at Wood Mackenzie, as saying. But he also pointed to significant challenges. “Infrastructure, suitable water and just the uncertainty associated with someone who’s not been doing that in the past on a large scale,” he said.

According to the report, several global players expressed interest after Namibia’s government put out a request for proposals to develop two separate but adjacent sites, where it envisions massive desalination plants.

The sites would also include wind and solar farms as well as electrolysers — systems that use electricity to split water into hydrogen and oxygen—which would be used to produce green hydrogen and ammonia for export.

Namibia received nine bids from six developers for the two sites, including South Africa’s Sasol Ltd., Australia’s Fortescue Metals Group Ltd. and Germany’s Enertrag AG—a shareholder in Hyphen Hydrogen Energy (Pty) Ltd., which has been awarded both sites.

In the global race for green hydrogen, Namibia is the latest sub-Saharan African country with major natural assets to position itself as a potential green energy hub.

The Hydrogen Stream: Storing hydrogen in offshore caverns

Tractebel and its project partners claim to have developed the world's first infrastructure and facilities concept for offshore hydrogen caverns. Image: Engie Tractebel

The Tractebel engineering subsidiary of French utility Engie is part of a partnership which has developed an offshore concept for the storage of hydrogen in caverns, a system the project partners have called a global first. “The design study … outlines an innovative solution for large scale hydrogen storage on the high seas: A scalable offshore platform for the compression and storage of up to 1.2 million m³ of hydrogen,” Engue wrote last week. “Underground salt caverns will be used as storage and buffer for the hydrogen produced offshore before the gas is transported via the pipeline network to the onshore grid, and finally to consumers and customers.” The storage and compressor platforms can reportedly process 400,000Nm3 (normal cubic meters) of hydrogen per hour, with the energy storage medium stored in underground salt caverns at a pressure of up to 180 bar.

The European Commission has approved, under EU state aid rules, a €900 million German scheme to support investment in the production of renewable hydrogen in non-EU countries, which will be then imported to the EU. “The scheme, called H2Global, aims at meeting the EU demand for renewable hydrogen that is expected to significantly increase in the coming years, by supporting the development of the unexploited renewable resource potential outside the EU,” wrote the commission yesterday. The ten-year project will be managed by special-purpose entity Hint.co. “This intermediary will conclude long-term purchase contracts on the supply side ([for] green hydrogen production) and short-term resale contracts on the demand side (green hydrogen usage),” said the commission. Prices will be determined via a double-auction model, where the lowest bid price for hydrogen production and the highest selling price for hydrogen consumption will each be awarded contracts.

Spanish company H2B2 Electrolysis Technologies is developing a project to generate up to 1,000kg per day of solar-powered emission-free hydrogen in California. The SoHyCal project, in Fresno County, consists of the construction, financing and operation of a renewable hydrogen production plant using polymer electrolyte membrane (PEM) technology, and with a nameplate capacity of up to 3,000kg per day.

The government of Western Australia is backing its hydrogen industry with three projects set to receive support from its lead agency services. Province Resources' HyEnergy Project will harness 8 GW of solar and wind power generation capacity to produce around 550,000 tons of hydrogen per year. The Murchison Hydrogen Renewables facility will use solar and wind to produce 5.2 GW of electricity to power the production of hydrogen which will be converted into 2 million tons of green ammonia annually. It is expected InterContinental Energy's Western Green Energy Hub will use up to 50 GW of solar and wind capacity to produce up to 3.5 million tons of hydrogen or 20 million tons of green ammonia per year.

Hydrogen-powered equipment was mentioned as part of Hyundai Construction Equipment‘s plan to invest €150 million into its Ulsan production plant, in South Korea, to increase capacity by 50% to more than 15,000 machines per year. “The move will support Hyundai’s growing presence in the booming global construction equipment market while providing a manufacturing base for a new generation of electric and hydrogen-powered equipment,” the company wrote yesterday.

Sweden has shown it has the potential to become a pioneer in green steel production, according to a note released today by U.S.-owned analyst Wood Mackenzie. The Nordic nation produces 3.2% of the crude steel made in the EU and U.K. Sweden's steelmakers expected to bank on the cost reductions offered by alkaline electrolysis technology, as well as benefiting from the declining cost of renewables and rising carbon prices, according to WoodMac. “At a levelized cost of electricity at $30/MWh, wind power is a highly economical source of power generation in Sweden today,” wrote the analyst. “Further cost reductions are expected, with better financing structures for onshore wind, lower capex [capital expenditure levels] for onshore and offshore installations, technological optimization for asset management, and state support for offshore grid infrastructure.” WoodMac added, the combination of hydrogen from alkaline electrolysis and energy from onshore wind is the most cost-effective option for green crude steel production in Sweden. “Assuming a carbon price of $100/ton, green steel producers could benefit from $85/ton of carbon credits,” wrote the analyst. “Better financing models for onshore wind and 48% lower capex for alkaline technology in 2025, yield [a] steel cost of $360-390/ton in carbon price scenarios ranging between $50/ton and $150/ton.”

This copy was amended on 21/12/21 to add details of the SoHyCal project.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.