Sio Silica wants to pump pure sand from aquifer that serves as drinking-water source for tens of thousands

An Alberta mining company wants to drill thousands of wells in southeastern Manitoba to remove millions of tonnes of sand in an aquifer that serves as the source of drinking water for tens of thousands of people.

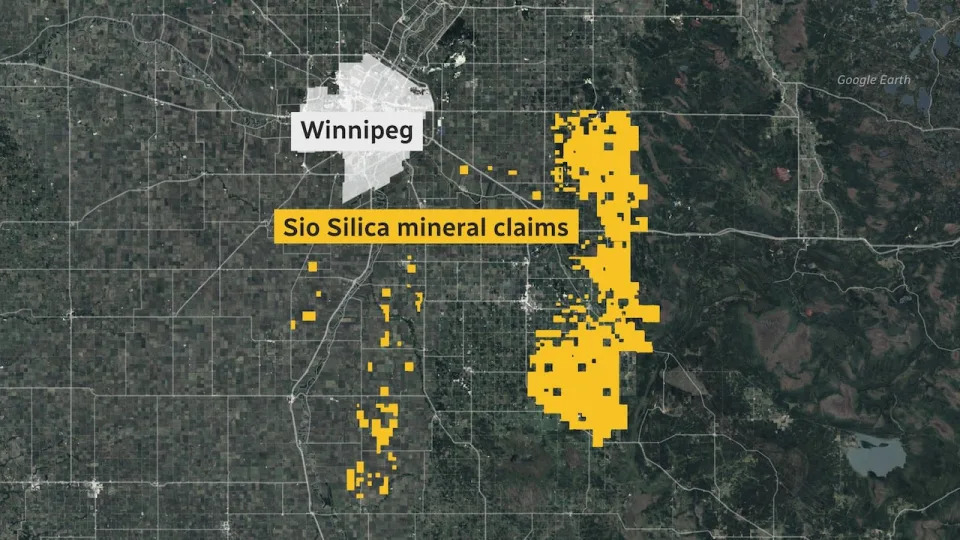

Calgary-based Sio Silica is seeking provincial environmental approval to drill up to 7,200 wells to the east and southeast of Winnipeg over 24 years and extract up to 33 million tonnes of ultra-pure silica sand from about 50 metres below the surface.

The mining company says its proposal will inject billions of dollars into the Manitoba economy by tapping into a Canadian supply of a highly sought after raw material required for the production of solar panels, new batteries and semiconductors.

Hundreds of residents of southeastern Manitoba, however, fear the potential contamination of their drinking water by a mining process that's never been tried on this scale anywhere on Earth.

The commodity coveted by Sio Silica is ultrapure crystalline quartz, which is 99.85 per cent free of contaminants such as boron, thorium, uranium and other elements that diminish the industrial value of silica.

"That sand is not easily obtainable around the world. The deposit in Manitoba is probably the largest high-purity, scalable deposit in the world," said Brent Bullen, Sio Silica's chief operating officer, during a visit to Winnipeg earlier in May.

A veteran mining industry executive who's worked in Canada, Kyrgyzstan, Qatar, Russia, Germany and Poland, Bullen said Sio Silica originally came to Manitoba in search of "frac sand" for use in horizontal oil drilling.

Sand producer shifts from oilpatch drilling to solar manufacturing with new facility in Manitoba

The company changed tack, he said, when it realized a vast quantity of critical minerals lies within a geological formation called the Winnipeg Sandstone Aquifer.

Seeking to drill 300 wells a year

Sio Silica proceeded to buy up subsurface mineral claims, mostly in an arc of land east of Winnipeg, where the sandstone aquifer is close enough to the surface to be reached by drilling conventional 16-inch-wide wells — yet still far enough below ground, the company claims, to prevent the surface from collapsing after sand is sucked out below.

In documents filed with the Clean Environment Commission (CEC), Manitoba's environmental regulator, Sio Silica intends to drill about 300 wells a year in Manitoba.

By injecting air into the pipe, sand would be extracted from each well for five to seven days. Outside the well, a slurry of sand and water would be piped to a processing facility planned for a former patch of forest south of Vivian, Man., in the Rural Municipality of Springfield, about 50 kilometres due east of Portage & Main.

Sio Silica's plan calls for the sand to be purified further at the processing plant and then shipped by rail to customers. Excess water would be cleaned and piped back underground.

WATCH | How the mining process would work:

How the mining would work

1 day ago

Duration0:32

Bullen calls the process "sustainable mining" and insists it will have no noticeable effect on the environment, unlike surface mining for lower-grade silica, which can leave scars behind on the surface and beaches bereft of sand.

Experts in geology, hydrology and water chemistry hired by the CEC are less enthused.

Manitoba orders public hearing on proposed silica sand mine in RM of Springfield

In reports prepared for the commission, they raise concerns about changes to water quality that may result from thousands of new wells that would puncture a relatively impermeable layer of shale, a crumbly sedimentary rock, on the way down into the sandstone aquifer.

Those additional wells, they say, will cause water from the Winnipeg Sandstone Aquifer to mingle with water above the shale, where the Red River Carbonate Aquifer has a different water chemistry.

"There will certainly be an exchange of groundwaters between the aquifers. There will be an irreversible change where mixing of these two aquifers will occur," a trio of engineers with the consulting firm KGS wrote in a report for the CEC.

'A precautionary approach is important'

The consultants also argued Sio Silica has only modelled subsurface water flows, without demonstrating them in the field, using a larger cluster of test wells.

Other consultants hired by the environmental regulator raised concerns about potential leaks of polyacrylamide, a chemical that would be used in the processing facility.

They also flagged what they considered a reluctance on the part of Sio Silica to consider the effects of improperly built or capped wells, as well as a failure to model how thousands of additional wells may interact with future residential or industrial development in southeastern Manitoba.

"Since groundwater is the main source of potable water for thousands of Manitobans, a precautionary approach is important," wrote Louis-Charles Boutin, an engineering consultant with Matrix Solutions, in a report for the Clean Environment Commission.

WATCH | What silica mining critics fear:

What silica mining critics fear

1 day ago

Duration0:31 What critics fear could happen if silica mining in southeastern Manitoba is approved.

Some Manitobans who draw their drinking water from the same aquifers are even more skeptical of Sio Silica's plans.

"This science has never been tried," said Bradley Simmons, an aircraft maintenance engineer who lives on 60 hectares of mostly wooded land a few kilometres west of Sio Silica's proposed processing facility.

"Getting approved for 25 years seems like a long time, and for something that has never been done before. Why couldn't we just do a couple years for trial purposes, test the well water and see what happens underneath us?"

Simmons is one of several hundred Manitobans who registered opposition to Sio Silica's proposal during Clean Environment Commission hearings that took place in Anola, Beausejour and Steinbach in February and March.

Concerns mount in southeast Manitoba over proposed silica sand mining project near Vivian

Many are members of Our Line in the Sand, an organized opposition group that formed in 2020, after some property owners were told they could not subdivide their land because of mineral claims below.

'This project shouldn't even be considered'

Our Line in the Sand president Tangi Bell said it's shameful that successive NDP and Progressive Conservative governments shepherded the mining proposal along without notifying residents.

"Ethically, this project shouldn't even be considered. It is taking place directly in the only freshwater drinking source for southeast Manitoba," said Bell on her acreage, which sits a few kilometres northwest of the proposed silica-processing site.

"We should know better at this point in our lives to sacrifice, and they're asking us to sacrifice this water for decarbonization plans."

Greg Nesbitt, Manitoba's natural resources minister, declined to comment on the Sio Silica proposal while it remains before the Clean Environment Commission.

Bob Lagasse, the Progressive Conservative MLA for Dawson Trail, which encompasses the Vivian area, said he will abide by whatever the commission decides.

"When this project came across my desk at the beginning, I had already started pushing behind the scenes to have this go to the Clean Environment Commission, because it hasn't been done," said Lagasse in a phone interview.

"It's an unknown, right? So leave it to the experts to decide, and we'll have to look at their determination."

Patrick Therrien, the mayor of Springfield, called the deliberations volatile. Some residents with environmental concerns clashed with proponents of economic development, which includes a proposal by German company RTC to build a solar-panel manufacturing plant in Manitoba if Sio Silica's plans are approved.

"There's going to be people that are not happy with either decision that comes out from the CEC, and we just have to be prepared one way or the other," said Therrien.

'Once it's gone, it's gone'

The concerns are not just environmental. Georgina and Josh Mustard, who live with their eight children on 47 hectares of land immediately to the west of Sio Silica's proposed processing facility, are uneasy about the prospect of an industrial plant opening up in what used to be a relatively pristine forest.

"If this goes through, it's obviously going to affect us first, but it's going to affect thousands and thousands of people," Georgina Mustard said at a picnic table outside her home earlier in May.

"We bought this place to secure for our family and our kids and if this goes through and things go wrong, then what? Then we have to leave? We have to uproot everything we know?"

Josh Mustard, who has worked on oil and gas projects across Canada, said he's seen the effects of industrial spills first hand.

He also said he doesn't believe Sio Silica's claims about sustainability or the protection of groundwater.

"There's no replacing it. Like, once it's gone, it's gone. That's the problem with mining: you're removing a resource," he said.

"We have open silica here in Manitoba. So why aren't we chasing that, without disturbing aquifers and groundwater and residential areas?"

Bullen said he sat through the Clean Environment Commission hearings and listened to testimony from residents. He said some were victims of what he called misinformation about the possibility of earth collapsing around his company's proposed wells or wells being drilled without the consent of property owners.

No expert hired by the commission is concerned about collapses, he said. Sio Silica will only drill where property owners allow the activity, he added.

UGLY ILL FITTING SPORTS COAT

"It's fear: Fear of change, fear of the unknown," Bullen said. "When we went through the hearing, we watched a lot of emotion and we just had to listen to the emotion."

Company says it's using existing technology

Bullen said he's confident his company's consultants have laid out a case for the safety of the mining proposal, which he described as more proven and less experimental than opponents claim.

"What we've done is we've taken existing technologies and we've just applied them in a different manner," he said. "My argument is we've patented an application in a process of an existing technology and we just happen to be the first to patent it."

As for people who fear contamination of their wells, Bullen said there are already 20,000 holes drilled into the aquifer, which is greater than the number of wells Sio Silica would ever drill.

This argument does not cut it for Josh Mustard.

"Yeah, we're tapped into it, but we're not sucking sand out, doing mass destruction," he said.

If the Clean Environment Commission approves Sio Silica's proposal, Tangi Bell said Our Line in the Sand would launch a judicial review. But that would require fundraising, she said.

Sio Silica, meanwhile, has already sunk about $40 million into its Manitoba mining proposal.

The Clean Environment Commission must issue a decision about Sio Silica's plan by June 22.

Residents raise concerns over silica mining

Duration3:51

Stock image.

Stock image.