SmartPropulsion: A Game Changer for Reducing Fuel & Ensuring Compliance

Across the global marine industry, environmental sustainability and economic efficiency are becoming increasingly intertwined. Vessel owners and operators face pressure to adopt fuel-saving solutions to meet the ever-tightening regulatory standards such as the 2050 zero-emission target, as well as market expectations for greener shipping.

While many technologies promise efficiency improvements, they are often costly, complex to implement, and in some cases, simply cannot deliver the results they initially promise. This puts marine businesses at an impasse; if they fail to meet regulations, they simply cannot operate the ship. Even if they do comply today, they must achieve and maintain a CII rating that meets changing regulations. While also contending with rising fuel costs and new carbon tax legislation, making it critical to reduce operating costs.

Against such uncertainty, shipowners need to be sure they are making the right decisions, not only to ensure their profitability and compliance now, but to de-risk their future. The industry seeks a solution that is cost-effective to install, does not require dry docking, and guarantees the necessary fuel savings. One proven technology delivers all this and more, known as SmartPropulsion and it achieves impressive results.

SmartPropulsion – a game changer

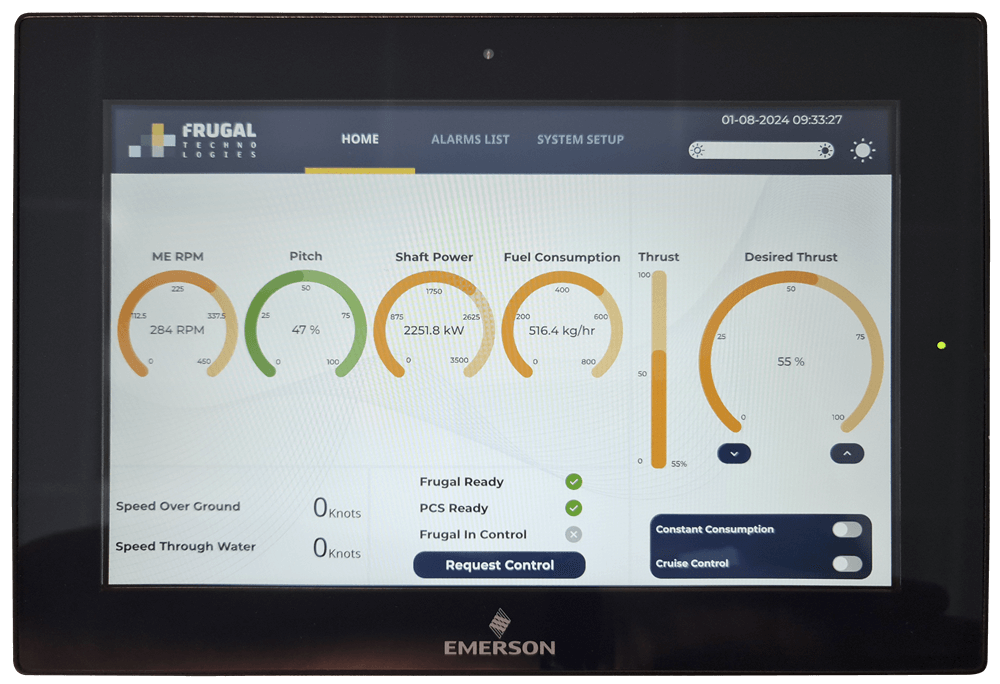

SmartPropulsion is an energy-saving solution from Emerson, powered by Frugal Technologies, that optimizes propulsion efficiency through AI and machine learning by monitoring and learning a vessel’s operating parameters in real time.

The reduction varies in accordance with propeller types, however a proven fuel saving of up to 15% has been documented in vessels equipped with CPPs, while fuel savings of up to 5% is documented in vessels equipped with FPPs. Every vessel goes through a business case evaluation, based on historical data, that evaluates the feasibility and return on investment. Not only does this mean they can save significant amounts on fuel costs, but SmartPropulsion also helps vessels to comply with existing and upcoming emissions regulations and achieve an optimal CII rating.

"We are proud to introduce SmartPropulsion, our latest innovation in collaboration with Frugal Technologies. Emerson is committed to making the world healthier, safer, smarter and more sustainable. With SmartPropulsion, we are taking a significant step forward in our commitment to sustainability, supporting our customers to navigate their daily challenges and realize their decarbonization goals." Jakob Noerr, vice president, marine solutions, Emerson.

Minimal CAPEX with significantly reduced OPEX

SmartPropulsion is compatible with all vessel types, engines, fuels, and propulsion systems. As an on-top solution, it interfaces directly with the existing Propulsion Control System, rather than the engine or propeller itself. This ensures proper equipment safety and gives a lower implementation cost compared to other energy-saving technologies.

Installation can be completed in three days, with no dry dock or off-hire days. This means vessels can be back in operation extremely quickly and can start delivering significant OPEX savings, with full return on investment (ROI) in as little as six months. The solution requires minimal training and, as a software-driven solution, maintenance is virtually non-existent.

Data-driven intelligence

SmartPropulsion uses cloud technology to combine Model Predictive Control and machine learning to collect and analyze data from the vessel’s operational parameters to create optimal propeller curves.

This means the system learns from experience over time. So, the longer it runs, the better it tracks the condition of the vessel and the more optimized the propulsion system becomes. On top of this, the vast amount of data collected can be integrated into existing intelligence solutions, generating insight for predictive maintenance. This enables users to solve any potential operational issues long before they become critical, saving considerable costs in repairs, associated downtime, and off-hire periods.

Proven results

SmartPropulsion is already proving its worth. Older vessels save more, but even relatively new vessels built according to old designs can have high savings.

For example, Uni-Tanker’s chemical tanker has seen a 12.2% improvement in fuel savings using SmartPropulsion, giving an ROI of only nine months and providing full documentation for CII reporting. Uni-Tankers was so impressed that they have installed SmartPropulsion on another eight vessels. Kristian Larsen, Technical Director at Uni-Tankers, commented: “With SmartPropulsion, we have a system that enables us to reduce the climate impact of our fleet while at the same time strengthening our competitiveness.”

In addition, Christiania Shipping has fitted two tankers with SmartPropulsion, giving an estimated 8-12% fuel savings each. Based on positive results Christiania Shipping upgraded more ships and now has eight CPP vessels and four FPP vessels installed with the solution. The FPP vessels are saving 2-4% of fuel and SmartPropulsion is also handling shaft power limitation according to calculated EEXI limits. Following these results, Christiania Shipping is planning to upgrade more of their vessels.

.png)

Based on data from already installed ships, we can estimate the fuel reduction for a typical container vessel of 6K TEU capacity with FPP. With 240 annual sailing days on average, it will consume an estimated 24K mt fuel. With SmartPropulsion installed, we can estimate a saving of approximately $4500K per year and ROI can be achieved in four months or less. Additionally, an estimated 2200mt of Co2 emission could be saved annually, significantly improving the CII rating for the vessel.

One to watch

Most vessel owners, managers, and operators would be pleased to gain even a one percent improvement in fuel efficiency. With SmartPropulsion, as much as 15 percent can be achieved, depending on the vessel's design, setup, and operational pattern. When other important factors are also taken into consideration, such as minimal implementation costs, significantly reduced OPEX, and low EU ETS costs, this innovative new technology looks to be a clear winner in terms of efficiency, safety, and value.

As regulations change, there will always be technologies in development to help vessels meet them. However, for the impressive results it delivers, SmartPropulsion is something we can expect to see on many more vessels in the future.

Visit Emerson to learn more about how SmartPropulsion can help improve the operation of your fleet, or contact Naveen Hegde, director, propulsion control and optimization, Emerson.

This article is sponsored by Emerson.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.

Rolls-Royce Sells Naval Propulsor Business to Fairbanks Morse

Rolls-Royce Sells Naval Propulsor Business to Fairbanks Morse

As part of its ongoing strategy to hone its operations to improve financial results, UK-based Rolls-Royce is selling its naval propulsors and handling business to Fairbanks Morse Defense, a leading U.S. defense contractor. The sale comprises operations in Mississippi and Massachusetts, as well as the specialized naval handling systems unit in Peterborough, Canada.

The CEO of Fairbanks Morse George Whittier is calling it a transformative deal for the company which already offers a diverse portfolio of engines, motors, and systems for naval craft. Fairbanks Morse is a leading supplier for U.S. Navy vessels as well as the U.S. Coast Guard, UK Royal Navy, Royal Canadian Navy, and Royal Australian Navy.

“The way that our products and services complement each other is unmatched in the defense industrial base,” said Whittier. “Combining our capabilities allows Fairbanks Morse Defense to substantially increase what we offer to our U.S. maritime defense customers while also offering our systems and components solutions to Rolls-Royce's global customer base.”

The acquisition will include a range of propellers and waterjets for naval applications, as well as marine handling systems, which enable the deployment and recovery of manned and unmanned craft, and other cargo, from naval vessels. Rolls-Royce says that its propulsion equipment can be found on more than 95 percent of the U.S. Navy Surface Warfare fleet, including on all the U.S. aircraft carriers currently in service. In 2021, the company reached an agreement with Fincantieri Marinette Marine to design and manufacture up to 40 propellers for the Constellation-class (FFG-62) guided missile frigate program.

Rolls-Royce has two facilities in the United States including its marine propeller and waterjet manufacturing campus in Pascagoula, Mississippi that is responsible for producing controllable pitch propeller blades and hub body castings, large fixed-pitch propellers, and waterjets for the U.S. Navy.

According to the company, it is the country’s only privately owned foundry that is qualified to cast propellers for the U.S. Navy’s surface and submarine fleet, making it a United States National Asset. In 2022, the U.S. Department of Defense through the DPA Title III program provided a grant to support the construction of a new 26,000 facility, with foundry and machining equipment in Pascagoula.

The facility in Walpole, Massachusetts also works with ship propulsor systems and aftermarket services for the U.S. Navy, U.S. Coast Guard, and other international navies. It supports controllable pitch propellers, fixed propellers, and waterjets.

In addition to the propulsors, Fairbanks Morse Defense is acquiring Rolls-Royce Peterborough, Canada which supports the design and manufacture of handling systems, launch and recovery systems, and undersea sensors and systems for navies across the globe. Its products include the next-generation Mission Bay Handling System for the Global Combat Ship program, a frigate program for the UK Royal Navy, Royal Canadian Navy, and Royal Australian Navy.

They are also used on U.S. Navy fleet supports, amphibious ships, surface combatants, submarines, and more, as well as on U.S. Coast Guard vessels. Rolls-Royce handling systems are found on many of the U.S. Navy’s surface combatants.

Terms of the acquisition were not announced and the closing is subject to regulatory review and approval. Rolls-Royce will retain its Naval Gas Turbines and Generator Sets operations, which provide power dense solutions for naval propulsion and onboard power needs

No comments:

Post a Comment