Sweden Looks to Lend $23 Billion to New Nuclear Power Projects

Sweden’s government will ask the Parliament to approve state loans worth $23.4 billion (220 billion Swedish crowns) to companies to build nuclear reactors in the Scandinavian country.

Sweden plans to build two new nuclear reactors by 2035 in a hedge on low-carbon energy security, with 10 new reactors hoped for by 2045.

The Swedish government moved to phase out nuclear power completely in 1980, but that decision was reversed by Parliament in 2010. Five years later, four aging reactors were shut down. Six of 12 reactors remain in operation in Sweden today.

The country is now betting on small modular reactors (SMRs) to expand its nuclear fleet as Stockholm seeks to further reduce emissions with low-carbon 24/7 energy.

Sweden has tweaked its renewable energy policy, which had called for 100% renewable electricity by 2040, changing the terminology to “100% fossil-free” electricity, paving the way for the construction of more nuclear power plants.

The Parliament of Sweden approved in late 2023 a new energy bill paving the way for the construction of additional nuclear reactors beyond the 10 originally approved.

Since Russia’s invasion of Ukraine and an energy-market-disrupting series of Western sanctions, nuclear power has regained much support in Europe as a critical aspect of reaching net-zero by 2050.

Sweden’s Vattenfall, the state-owned utility, last month shortlisted American company GE Vernova and British company Rolls-Royce SMR as potential suppliers of SMRs. Both suppliers could deliver within a reasonable timeframe and budget, taking into account the conditions of the Värö Peninsula along the Swedish west coast, Vattenfall said in August, adding that the process now continues towards selecting a final supplier.

Sweden’s state support for new nuclear reactors would help fund 2.5 gigawatts (GW) of nuclear power, Financial Markets Minister Niklas Wykman said on Friday.

“It's not a price tag... it is a loan framework that is needed to be able to conduct sharp negotiations,” the minister said, as quoted by Reuters.

By Michael Kern for Oilprice.com

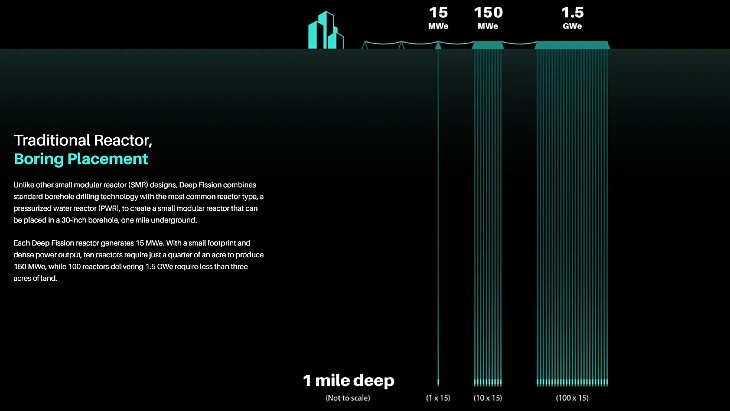

Three US states in line for Deep Fission's underground SMRs

California-based nuclear startup company Deep Fission announced its emergence from stealth mode in August 2024. It aims to locate 15 MWe pressurised water reactors about one mile (1.6 km) underground in a 30-inch borehole. The heat is transferred to a steam generator at depth to boil water, and the non-radioactive steam rises rapidly to the surface where a standard steam turbine converts the energy to electricity. It says its reactors are scalable from 15 MWe to 1.5 GWe.

It says that by locating the reactors underground “the surrounding geology provides billions of tonnes of natural shielding and passive containment” and minimises the surface footprint and forecasts a “70-80% overnight installed cost advantage compared to conventional nuclear technologies".

The company says that Letters of Intent have now been signed in each of the three states to pursue joint development projects, with Deep Fission CEO Elizabeth Muller saying: "We’re proud to collaborate with our partners in Texas, Utah, and Kansas. Together, we're laying the groundwork for the next era of nuclear energy in the United States. These projects reflect the urgent demand for reliable, carbon-free baseload power, and we are excited to be part of the solution to fill that need."

Deep Fission is one of the 11 companies selected by the US Department of Energy's Reactor Pilot Programme, which aims to see at least three of them achieve criticality by August 2026.

Meanwhile Deep Isolation, which like Deep Fission was co-founded by Elizabeth Muller and Richard A Muller, has announced a technology licensing agreement with Navarro Research and Engineering, Inc.

The licensing agreement “enables Navarro to leverage Deep Isolation’s patented borehole repository systems and canister technologies for nuclear and hazardous waste management, while ensuring that ownership of all licensed intellectual property, including patents and processes, remains with Deep Isolation”.

Industry groups urge governmental support for nuclear investments

_94613.jpg)

The OECD Nuclear Energy Agency and South Korea co-hosted the 3rd Roadmaps to New Nuclear 2025 conference in Paris, France. This annual event brings together government and industry leaders to address the most pressing issues for delivering new nuclear energy construction at the scale and pace required to meet the growing global expectations for nuclear energy.

During the meeting, the nine industry associations issued a joint communiqué calling on all OECD member states to "take the necessary steps to enable a stronger global economy with affordable and stable energy prices while ensuring energy security and meeting growing global demands for clean and abundant electricity".

"In particular we believe that there is a need to support investment in nuclear fission projects encompassing all nuclear technologies, from large scale nuclear new build, to power uprates and lifetime extensions of existing reactors, to development and deployment of small modular reactors (SMRs) and microreactors."

The associations call for governments to ensure the long-term operation of all existing nuclear reactors for which it is technically feasible and to ensure "consistent and coherent" long-term policies to facilitate new nuclear projects. They also say there needs to be support for the entire nuclear value chain, including the nuclear fuel cycle with special focus on mining, conversion and enrichment to ensure security of nuclear fuel services from OECD countries.

Governments must also apply technology neutrality to clean energy sources, to achieve a successful expansion of the energy sector, essential both for end consumers of energy and to provide clear signals for investments in the nuclear sector. They should also build on the World Bank's openness to funding nuclear energy projects, and enable access to public financing at the national and multi-national level which will also facilitate private financing.

The industry groups also call for the support of a "strong and collaborative" nuclear supply chain, to maximise the OECD's potential to deliver new projects within the OECD and in other countries. They also encourage stronger cooperation between regulators to enable greater design standardisation, which will reduce costs and facilitate fleet deployment.

"We stand ready to continue working with governments in their commitment to support nuclear development to meet climate and energy security imperatives," the statement said.

It was signed by the heads of the Canadian Nuclear Association, EPRI, GIFEN, Japan Atomic Industrial Forum, Korean Atomic Industrial Forum, Nuclear Energy Institute, Nuclear Industry Association, Nucleareurope and World Nuclear Association.

Addressing the Finance session, World Nuclear Association Director General Sama Bilbao y León said: "Tripling global nuclear capacity is not just a goal - it is a necessity. To meet climate targets, ensure energy security, and power prosperity, progress and sustainable development for everyone everywhere, we must accelerate deployment, streamline regulation, and scale innovation.

Mega cooling tower completed at Chinese unit

_42577.jpg)

The final concrete for the circular foundation of the tower was poured in November 2023. The foundation is more than 10 metres wide and more than 2 metres thick. A total volume of about 15,900 cubic metres of concrete was used to form the foundation.

The cooling tower now has a height of 218.7 metres and a diameter at its base of about 175 metres. A total of 137,400 cubic metres of concrete was used in the tower's construction. The water spraying area of the tower is 20,000 square metres. It mainly consists of a foundation, inclined pillars, tower tube, and inlet. It consists of a central water shaft, water distribution system, heat exchange filler, water collection system, main water collection tank, and water eliminator.

SPIC said that, with the main structure now complete, the installation of internal components of the tower is set to begin.

"The successful completion of the cooling tower has accumulated valuable experience for the design and construction of ultra-large seawater cooling towers in China's nuclear power field," SPIC said.

The company noted that, unlike the 'once-through cooling' model commonly used in traditional nuclear power plants, the 'secondary circulation cooling technology' used in the cooling tower of Lianjiang 1 represents "a new technological breakthrough". It said this technology replaces direct seawater extraction and discharge with the reuse of cooling water. Using the atmosphere as the ultimate heat sink, it recycles cooling water through air-water heat exchange.

"This significantly reduces water intake, greatly minimising the operational risk of marine organism infestation at the nuclear power plant and enhancing the safety and stability of power supply," SPIC said. "Furthermore, water discharge is significantly reduced to one-fortieth of that of traditional nuclear power plants, and the discharge temperature approaches that of natural seawater, further enhancing the environmental friendliness of the nuclear power project."

The first phase of the Lianjiang nuclear power plant project - the first coastal nuclear power project developed and constructed by SPIC in Guangdong - will comprise two CAP1000 units. The site is eventually expected to house six such reactors. It is the first nuclear power plant in China to adopt seawater secondary circulation cooling technology, and is the first to develop and use a super-large cooling tower.

The construction of the first two 1250 MWe CAP1000 reactors - the Chinese version of the Westinghouse AP1000 - at the Lianjiang site was approved by China's State Council in September 2022. Excavation works for the units began in the same month. The first safety-related concrete for the nuclear island of unit 1 was poured in September 2023 and that of unit 2 in April last year.

Lianjiang unit 1 is expected to be completed and put into operation in 2028.

Construction starts of Belgian disposal facility

_19546.jpg)

The facility will consist of several concrete bunkers that will house large concrete vaults in which short-lived low- and intermediate-level waste will have been encapsulated with mortar. Currently, 28,831 vaults are planned, spread across two zones: 20 bunkers in the first and 14 in the second.

The Dessel facility will house all Belgian low- and intermediate-level, short-lived radioactive waste including that from nuclear power plants, hospitals, research institutes and the decommissioning of nuclear facilities. Currently, this waste is managed by national radioactive waste management agency ONDRAF/NIRAS's industrial subsidiary Belgoprocess in several dedicated buildings on the Dessel site.

The storage phase will last about 50 years. Afterward, the site will be permanently covered by several natural and artificial layers to prevent water infiltration. Two green hills approximately 20 metres high will then appear in the landscape. After filling, the facility and its surroundings will be monitored and controlled for 300 years. After that, monitoring will no longer be necessary to ensure safety.

A rendering of the new facility (Image: ONDRAF/NIRAS)

In 2006, the federal government approved the development of the surface storage project in Dessel. ONDRAF/NIRAS submitted an initial version of the licence application for the facility to the Federal Agency for Nuclear Control (FANC) on 31 January 2013. However, FANC declared that the dossier was incomplete and requested a number of additional clarifications and additions. ONDRAF/NIRAS submitted the completed version of the application to FANC in February 2019. A permit to construct and operate the facility was granted in 2023.

In June this year, the NucleusSafe partnership - a joint venture of Belgian contractors Deckx, BESIX, Vanhout and Stadsbader - was announced as the contractor for civil engineering works, with construction company Denys responsible for electromechanical aspects.

"This is a unique moment for our country, one of which I am very proud," said ONDRAF/NIRAS Director General Marc Demarche. "It took many years and a lot of effort on the part of our teams to meticulously prepare this disposal project. For example, the safety file is nearly 25,000 pages long, demonstrating in detail how we will guarantee safety for at least 300 years. Now it's up to the contractors to start the work and up to us to monitor it."

Prime Minister Bart De Wever added: "Nuclear technology is one of the keys to a better future. That is why, after years of hesitation, this government has finally abandoned the nuclear phase-out. Reliable and affordable energy, medical advances, or industrial safety: for many important applications, nuclear technology is crucial. Our country enjoys a solid reputation in these areas. With this fantastic project, we are once again strengthening our pioneering role in the safe and collectively supported storage of nuclear waste."

Belgium has yet to take a position on the final disposal of high-level and/or long-lived waste

British firm to acquire ODIN microreactor design

_56068.jpg)

Cambridge AtomWorks, which is led by University of Cambridge nuclear science leaders, is an advanced reactor developer that is already developing ODIN for NANO Nuclear on an outsourced consulting basis.

The letter of intent calls for a total purchase price of USD6.2 million, with a USD250,000 upfront non-refundable down payment to NANO Nuclear and a USD5.95 million payment in 2026 as well as future low single-digit royalties payable to NANO Nuclear based on net sales if and when ODIN is commercialised. The transaction remains subject to execution of definitive documentation and the satisfaction of customary closing conditions. The sale of ODIN is expected to be closed by the end of 2025.

According to company information, ODIN will use "conventional" uranium fuel with up to 20% enrichment (high-assay low-enriched uranium), with a low-pressure coolant to minimise the stress on structural components and improve their reliability and service life. It will also use a unique reactivity control system design, aiming to have high reliability and robustness by minimising the number of moving parts. The reactor will operate at higher than conventional water-cooled reactor temperatures, and take maximum advantage of natural convection of coolant for heat transfer to the power conversion cycle at full power and for decay heat removal during reactor shutdown, operational transients, and off-normal conditions.

NANO Nuclear said the sale of ODIN would streamline its product line, enabling it to concentrate resources on its related portfolio of gas-cooled, advanced, highly modular microreactors: the KRONOS MMR Energy System, LOKI MMR, and ZEUS.

"Following our acquisition of the patented, gas-cooled KRONOS MMR and LOKI MMR microreactor technologies earlier this year, NANO Nuclear has assumed a leadership role in advancing the next generation of nuclear reactors in the United States," said NANO Nuclear Founder and Chairman Jay Yu. "As our product portfolio expanded, we conducted an internal review to best align with the energy goals and the increasing demand for reliable power in our target markets. While we remain confident in the ODIN design, we concluded that a sale of the low-pressure cooled ODIN to a natural buyer familiar with the technology would allow us to move more efficiently going forward with our gas-cooled reactor portfolio."

NANO Nuclear highlighted that retaining the LOKI MMR and ZEUS microreactors was a strategic decision, as the reactors share most of their underlying features with the flagship KRONOS MMR Energy System.

"Continued development of our KRONOS MMR will have direct benefits for LOKI and ZEUS, providing value and benefit across our portfolio," said Florent Heidet, Chief Technology Officer and Head of Reactor Development at NANO Nuclear. "Together, they form a complementary offering, enabling us to achieve synergistic development, regulatory and ultimately commercial progress. As KRONOS MMR advances through construction and licensing, LOKI and ZEUS directly benefit from the aligned technology, regulatory, and supply chain efficiencies."

Super module in place at Lufeng unit 1

_84562.jpg)

With a hoisting weight of almost 990 tonnes and measuring more than 26 metres long, 29 metres wide and 23 metres high, the concrete and steel CA01 module - composed of 47 sub-modules - sits inside the unit's containment module where it will house the plant's reactor pressure vessel, steam generators and other components.

The installation of the CA01 module on 16 September marks "the entry of the unit into a new stage of structural construction and equipment installation", Shanghai Nuclear Engineering Research and Design Institute (SNERDI) said.

The CAP1000 reactor design - the Chinese version of Westinghouse's AP1000 - uses modular construction techniques, enabling large structural modules to be built at factories and then installed at the site. The CA01 module is referred to as a super module because it is too large to be transported by road and rail, and was constructed on site.

SNERDI - a subsidiary of State Power Investment Corporation - said the project team were faced with four major challenges in hoisting the CA01 module, which it describes as "the largest, heaviest, and most complex structural module in the nuclear island". These challenges were its complex structure, heavy weight, centre of gravity deviation, and millimetre-level positioning accuracy.

(Image: SNERDI)

"The project team achieved these breakthroughs through technological innovation and refined control," the company said. "Using laser scanning technology, the team created a full-scale digital replica of the module, accurately calculating the actual centre of gravity coordinates. Based on this information, they designed a dedicated multi-point hoisting system, equipped with a three-stage balance beam, to address the centre of gravity deviation caused by the module's T-shaped structure.

"By combining traditional contour line layout checks with 3D scanning collision checks, they were able to overcome the challenges of a confined installation area and minimal clearance from surrounding embedded components."

The first safety-related concrete was poured for the nuclear island of unit 1 at the Lufeng plant on 24 February this year. It is the third unit to begin construction at the site, which will eventually house six reactors.

The proposed construction of four 1250 MWe CAP1000 reactors (units 1-4) at the Lufeng site was approved by China's National Development and Reform Commission in September 2014. However, the construction of units 1 and 2 did not receive State Council approval until 19 August last year. Approval for units 3 and 4 is still pending.

In April 2022 the State Council approved construction of two Hualong One units at Lufeng as units 5 and 6. First concrete was poured for unit 5 on 8 September 2022 and that for unit 6 on 26 August 2023.

No comments:

Post a Comment