New biobased recyclable polyesters exhibit excellent tensile properties beyond polyethylene and polypropylene

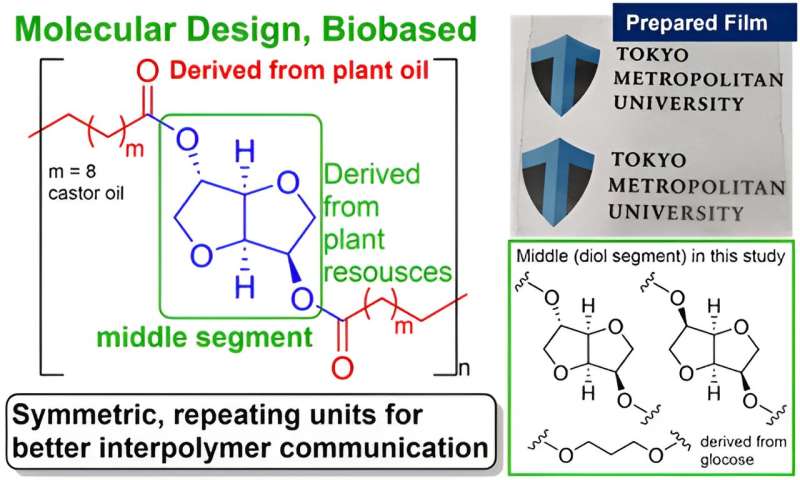

The research group of Professor Kotohiro Nomura, Tokyo Metropolitan University, in cooperation with the research group of Director Hiroshi Hirano, Osaka Research Institute of Industrial Science and Technology, has developed biobased polyesters from inedible plant resources, which can be easily chemical recyclable and exhibit promising mechanical properties in films than commodity plastics.

The work has been published in ACS Macro Letters.

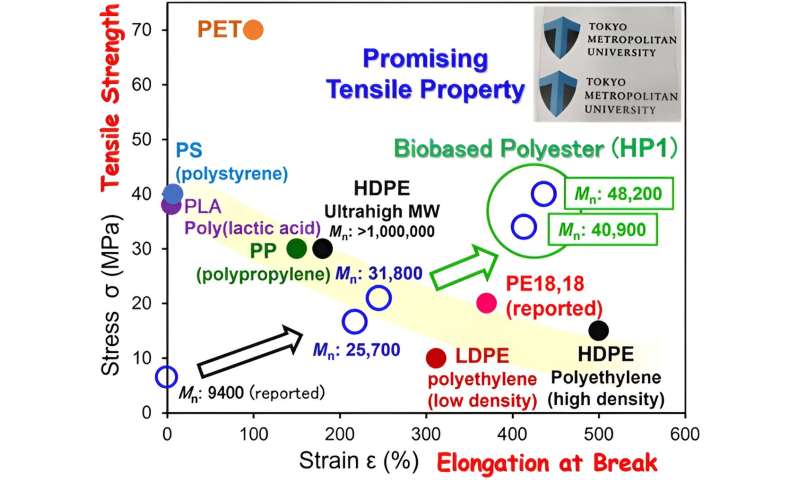

The development of high-performance, sustainable, recyclable plastics is important for the creation of a circular economy. Biobased polyesters made from plant resources are expected to become a promising alternative to commodity polymers such as polyethylene and polypropylene produced from petroleum. However, there have been few examples of the development of high-performance materials that exceed required mechanical properties such as tensile strength and elongation at break.

Synthesis methods for high molecular weight (long chain) polymers had been a pending issue in conventional polycondensation methods. To solve this issue, the research group has developed an olefin metathesis polymerization method using a high-performance molybdenum catalyst, focusing on polyesters derived from inedible plant resources.

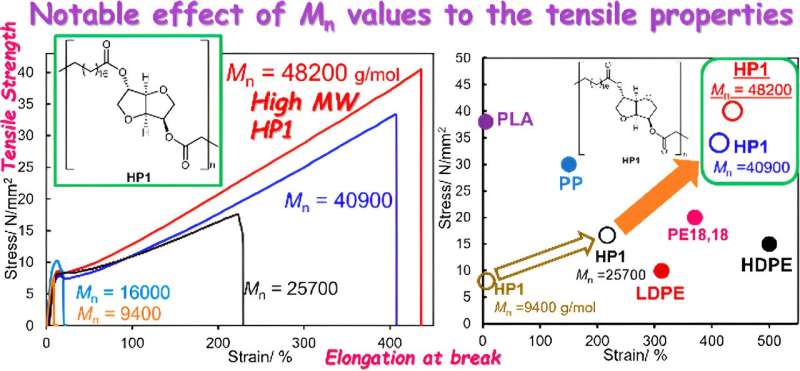

In general, there is an antinomic relationship between tensile strength and elongation at break in polymer film, as well as an increase in the molecular weight and the elongation at break. However, the present polymer film demonstrates that the tensile properties (strength and elongation at break) of the polymer film increased with the molecular weight, exhibiting superior properties beyond conventional plastics.

This method is the first success in developing the biobased polyester materials that can be decomposed/recycled. The film properties can be further improved by combining the material with naturally derived fibers such as cellulose nanofibers.

Olefin metathesis polymerization method

"Olefin" is a general term for hydrocarbons with one carbon–carbon double bond. The word "metathesis" means "substitution." Therefore, the recombination reaction of substituents on the double bond of an olefin is called the olefin metathesis reaction. For example, there is a reaction where a carbon–carbon double bond in an olefin is replaced with a catalytic metal–carbon double bond (catalytically active species) through the reaction using a catalytic metal such as ruthenium or molybdenum.

The polymer synthesis method using such a reaction is called the olefin metathesis polymerization method. The present method developed by the researchers is a polycondensation synthesizing polymer through producing ethylene as by-product (acyclic diene metathesis polymerization).

More information: Mika Kojima et al, Synthesis of High Molecular Weight Biobased Aliphatic Polyesters Exhibiting Tensile Properties Beyond Polyethylene, ACS Macro Letters (2023). DOI: 10.1021/acsmacrolett.3c00481

Journal information: ACS Macro Letters

Provided by Japan Science and Technology AgencyIron catalyst could make important chemical reactions cheaper and more eco-friendly

No comments:

Post a Comment