FUSION/SCI-FI-TEK

Korea completes delivery of ITER vessel sectors

The fourth and final ITER vacuum vessel sector manufactured by South Korea has been delivered to the construction site of the tokamak fusion device in Cadarache, southern France.

_25570.jpg)

The International Thermonuclear Experimental Reactor's (ITER's) plasma chamber, or vacuum vessel, houses the fusion reactions and acts as a first safety containment barrier. With an interior volume of 1400 cubic metres, it will be formed from nine wedge-shaped steel sectors that measure more than 14 metres in height and weigh 440 tonnes. The ITER vacuum vessel, once assembled, will have an outer diameter of 19.4 metres, a height of 11.4 metres, and weigh approximately 5200 tonnes. With the subsequent installation of in-vessel components such as the blanket and the divertor, the vacuum vessel will weigh 8500 tonnes.

Each vacuum vessel sector is manufactured in four segments, requiring more than 1.6 kilometres of welding for assembly. Maintaining precise tolerances of less than a few millimetres ensures the seamless integration of internal components, which demands advanced forming and welding technologies.

The completed sector (Image: Korea Institute of Fusion Energy)

The fabrication of the vacuum vessel sectors is shared between Europe (five sectors) and South Korea (four sectors). Initially, South Korea was tasked with producing two vacuum vessel sectors under its agreement with the ITER Organization. However, in 2016, an additional agreement was made to produce two more sectors originally assigned to the EU.

Starting with the delivery of the first sector in 2020, South Korea has now completed all four sectors, fulfilling its commitment to this significant international project.

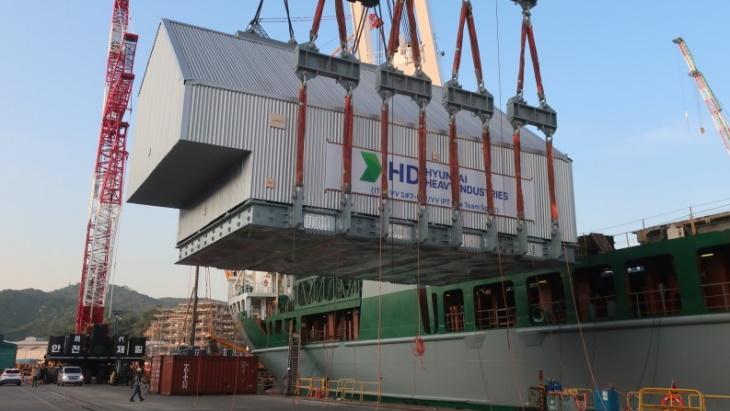

The sector is unloaded from the ship (Image: Korea Institute of Fusion Energy)

"Korea has also delivered superconductors, thermal shields, and assembly tools to ITER on schedule, steadily contributing to the development of fusion reactor technologies and supporting efforts toward the realisation of fusion energy," the National Research Council of Science and Technology noted.

The fourth and final sector was produced at Hyundai Heavy Industries' shipyard in Ulsan. After leaving Ulsan on 24 August, the load travelled around the Cape of Good Hope at the southern tip of the African continent and sailed north to the Strait of Gibraltar and into the Mediterranean Sea. It was delivered to the ITER site on 8 November.

Of the nine vacuum vessel sectors required to form the tokamak's toroidal plasma chamber, five are already present on site. The first sector produced by Europe was recently delivered to the site. In the ITER Assembly Hall, two sectors are being assembled into modules that will be installed later in the assembly pit. Another is undergoing repair in the former Cryostat Workshop, where two other recently arrived sectors have just been stored.

The sector arrives at the ITER site (Image: ITER)

ITER is a major international project to build a tokamak fusion device designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy. The goal of ITER is to operate at 500 MW (for at least 400 seconds continuously) with 50 MW of plasma heating power input. It appears that an additional 300 MWe of electricity input may be required in operation. No electricity will be generated at ITER.

Thirty-five nations are collaborating to build ITER - the European Union is contributing almost half of the cost of its construction, while the other six members (China, India, Japan, South Korea, Russia and the USA) are contributing equally to the rest. Construction began in 2010 and the original 2018 first plasma target date was put back to 2025 by the ITER council in 2016. However, in June this year, a revamped project plan was announced which aims for "a scientifically and technically robust initial phase of operations, including deuterium-deuterium fusion operation in 2035 followed by full magnetic energy and plasma current operation".