ALT. FUEL

Ship Managers Make Changes to IMO Net-Zero Framework to Avoid Legal Action

[By: InterManager]

Ship managers have expressed concerns in connection with the International Maritime Organization’s future net-zero framework and have suggested concrete changes which they believe would make the proposals more effective.

Acting on behalf of the global shipmanagement sector, InterManager, the international association for ship managers, has submitted a proposal to the next meeting of the IMO’s Marine Environment Protection Committee (MEPC83) to suggest important changes.

The submission warns that, in its current form, the greenhouse gas (GHG) proposal doesn’t properly account for the involvement of a third-party International Safety Management (ISM) Manager.

Highlighting that roughly 20% of the global fleet is operated by a third-party technical ship manager as the ISM Manager, the submission asserts the need for further refining to make it applicable in practice and to avoid future national implementing acts being open to inevitable and avoidable litigation by ship managers.

In comparison to the charterer and shipowner, the ship manager has no material influence over the GHG intensity of a ship. Ship managers have no say regarding the type of engine powering the managed ship, nor whether sails, solar, fuel cells or other installations are installed on board. Such choices are decided exclusively by the shipowner.

“Ship managers are not consulted and, in addition, have no influence as to which fuels are procured and supplied to any of the managed ships, neither contractually nor in practice. The matter is negotiated between the shipowner and the charterer and agreed in the charter party agreement for the ship, together with speed and consumption, the remaining significant parameters impacting on its GHG intensity,” the submission states.

However, the current proposed draft amendments to MARPOL Annex VI on the IMO net-zero framework suggest making ship managers the sole responsible entity for penalties related to GHG emissions. InterManager says this clearly misidentifies the ship manager as the polluter to be held responsible and penalised which, as well as being factually wrong, could lead to legal challenges.

Further, by assigning liability for compliance fees to the ship manager, they in turn, are forced to ask shipowners to provide upfront financial security to cover potential risks of insolvency or defaults. This forces significant amounts of equity to be tied up in security, limiting cash flow available for growth or investment in new ships.

InterManager President Sebastian von Hardenberg commented: “We Ship managers are fully committed to playing our part in shipping’s journey to net zero. However, when it comes to the GHG intensity of a ship, ship managers have no say whatsoever in any of the decisions that result in material impact; they are not even consulted. In shore terms, we are the Facility Managers, not the Factory Owners.

“In taking our points into consideration, the IMO can develop a more practical and equitable framework for decarbonisation that is supported by all stakeholders within the shipping industry,” he said.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Designs for NYK’s Ammonia Bunker Vessel Advances

As the industry prepares for the commercial introduction of the first ammonia-fueled marine engines, efforts are continuing to develop the infrastructure that will be needed to support ammonia at scale as a fuel for the maritime industry. Japan’s NYK Group (Nippon Yusen Kabushiki Kaisha) working in partnership with Seatrium and its design company LMG Marine, is reporting a groundbreaking step in advancing the sector.

The group’s design for an ammonia-fueled ammonia bunkering vessel has passed the next key milestone in its development. ClassNK reviewed the design engineering developed by LMG and issued the next Approval-in-Principle for the project. The partners report the design will now be submitted to the Maritime and Port Authority of Singapore for evaluation. Singapore hosted the first ammonia bunkering operations and certification program in early 2024 for the converted offshore support vessel developed by Fortescue.

The AiP certification validated the ammonia-fueled ammonia bunkering vessel design’s compliance with stringent safety, technical, and environmental standards. LMG Marin provided design capabilities, leading to a Hazard Identification Study (HAZID) for design validation. The comprehensive HAZID conducted was instrumental in ensuring optimal safety, performance, and operational reliability.

The partners report the vessel design incorporates the consortium's two key features to ensure safety and operational reliability. It uses ammonia fuel dual-fuel engines from IHI Power Systems and a bunkering boom by TB Global Technologies. The bunkering boom features a unique technology called the High Speed Ammonia Purging Emergency Release System (ERS), which enables a reliable and efficient disconnection between vessels in an emergency.

NYK is already at the forefront of ammonia-fueled shipping. In 2024, it completed the conversion of its pioneering LNG-fueled tugboat Sakigake into an ammonia-powered vessel. It completed one of the first ammonia bunkering operation which used truck-based delivery and the vessel is now demonstrating operations in Tokyo Bay.

The effort to develop an ammonia bunker vessel began several years ago. In September 2022, the project received its first AiP certification based on a 3D model.

NYK said the design for the bunker vessel is an essential contribution to developing the infrastructure needed for ammonia bunkering. The designs will be reviewed by the authorities in Singapore, which already is one of the world’s largest bunker ports, and seeks to be a hub for innovation.

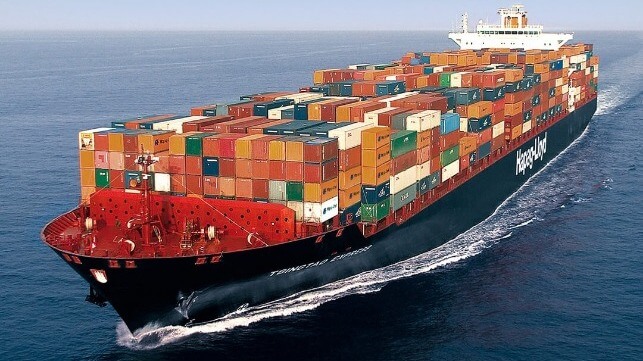

Buyers Alliance Launches Large Tender to Support E-Fuel Container Shipping

The buyers' alliance established in 2023 to spur demand for decarbonization in shipping officially opened its second, larger tender for shipping services this time requiring the use of the e-fuel. It comes as the first contract which was awarded to Hapag-Lloyd for low-emission shipper services is set to kick off in 2025 and run into 2026.

The concept behind the initiative known as ZEMBA (Zero Emission Maritime Buyers Alliance) and facilitated by the Aspen Institute builds demand by aggregating the shipping needs of members ranging from Ikea and Nike to Levi Straus and Electrolux. Over forty major manufacturing and consumer brands are currently members of the alliance. The group launched its first tender in 2024 saying the goal was to accelerate commercial deployment of clean energy powered shipping. By aggregating demand, they are enabling economies of scale and building lead-edge demand to encourage the shipping and fuel industries to pursue their initiatives.

Under the first tender, well-known brands including Amazon, Patagonia, Bauhaus, New Balance, Nike, REI, and others agreed to purchase over one billion TEU miles on the route between Singapore and Rotterdam in 2025 and 2026. Hapag as the winner of the tender agreed to provide an independently certified and exclusive waste-based biomethane service.

The second tender launched today and accepting proposals through the spring of 2025 shifts to a focus on e-fuels. ZEMBA reported in October 2024 that a survey of the industry found sufficient predicted supply of both e-methanol and e-methanol-capable vessels in the container segment to support ZEMBA’s focus on e-fuel deployment. They noted however that many producers remained at the pre-FID stage, casting doubt on whether those projects would begin production on projected timelines and, related, if e-fuel-capable dual fuel vessels would actually run on e-fuels without spurring demand.

With the second tender, ZEMBA intends to aggregate approximately 86 billion tonne nautical miles of demand for the emissions abatement associated with e-fuel-powered shipping to be deployed starting in 2027. This equates to 1.5 million TEU transported across the Pacific by e-fuels, assuming a benchmark distance of Shanghai to Los Angeles and projects enabling companies to abate approximately 500,000 metric tonnes of greenhouse gas (GHG) emissions, subject to final commercial details.

“Getting e-fuel-powered shipping on the water for the first time through this collaborative forward procurement will be a huge technical and commercial innovation milestone for the sector,” said Ingrid Irigoyen, President and CEO of ZEMBA.

A qualifying bid for ZEMBA’s tender will be a proposal from a containership carrier or consortium for e-fuel-powered shipping for three to five years, starting around 2027. All bids must demonstrate at least a 90 percent lifecycle emission reduction for the primary propulsion of the vessels compared to a high-emission fuel baseline.

ZEMBA will select the best proposal(s), and after vetting and commercial negotiation, members will enter bilateral contracts with the winner(s). For this tender, ZEMBA is open to the potential of multiple winners. Results of the second tender are expected to be announced by the end of 2025.

NorthStandard, CORE POWER and Lloyd’s Register Call for UK Action

[By: NorthStandard]

New paper proposes framework to support UK development of advanced, safe, small nuclear reactors as a reliable and scalable zero-emission maritime power source.

The UK is well positioned to lead the safe development and deployment of new nuclear power systems for commercial ships and Floating Nuclear Power Plants (FNPPs), according to a new report from CORE POWER, NorthStandard and Lloyd’s Register (LR).

Technology company CORE POWER, global marine insurer NorthStandard and maritime professional services provider LR have jointly published Advanced Maritime Nuclear: A unique opportunity for the UK. The new paper sets out a policy framework for the UK Government to support the deployment of advanced small nuclear reactors on commercial ships and FNPPs.

The Department for Transport should include nuclear-powered shipping and FNPPs in an updated Clean Maritime Plan (CMP) and long-term nuclear strategy, the report argues.

Global shipping currently depends on fossil fuels for close to 99% of its energy consumption, but the International Maritime Organization (IMO) is aiming for its greenhouse gas (GHG) emissions to reach net zero by around 2050. However, alternative fuels options (including biodiesel, methanol, hydrogen and ammonia) face major cost, production, transportation and use challenges.

In the foreword to the paper, Lord Mountevans comments: “The UK has the skills, expertise, and history of innovation to lead the development of nuclear-powered shipping. By leveraging our decades of experience with small reactors for the Royal Navy, we can decarbonise maritime transport, create jobs, and strengthen Britain’s position as a clean energy world power.”

The UK pledged to triple nuclear energy generation capacity at COP 28. The Civil Nuclear Roadmap to 2050, published by the last government, envisaged nuclear technologies, from Advanced Small Modular Reactors (A-SMRs) to large-scale nuclear plants as part of the UK’s energy mix. These new, safe and advanced nuclear technologies in modular designs, which allow for straightforward manufacturing and regulatory approval processes that enable dramatic energy efficiency gains for global shipping. NorthStandard’s participation in the new paper reflects the role commercial insurability will play in future nuclear operations in the civil maritime space, particularly to cover shipowners’ liability.

Paul Jennings, Managing Director, NorthStandard, commented: “The ability to commercially insure nuclear propelled ships will be vital to the success of bringing nuclear to maritime. It is important that governments understand the need for a civil marine nuclear liability convention within the framework of IMO and work towards creating an appropriate liability regime.”

With the right investments and policies, the UK can develop a multi-billion-pound industry according to the report. In addition to zero pollution, nuclear powered ships would not rely on shore power in port and could even feed electricity into the grid.

FNPPs could also be used to alleviate the issues surrounding shore power and expensive connections to the UK national grid.

CORE POWER’s founder and CEO, Mikal Bøe, said: "History has shown that there has never been a great naval power that wasn't also a great maritime power. Maritime nuclear is the catalyst that can reverse the trajectory of the British shipping sector, creating unique competition to Chinese shipbuilding and ocean transport. The UK has been at the centre of global shipping for centuries, and this report reinforces that maritime nuclear power is not only necessary to improve the energy effectiveness of shipping dramatically but also a £2.5 trillion economic opportunity. Over time, the cost of inaction will far outweigh the cost of being the champion in this rapidly emerging market.”

Commenting on the launch of the research paper, Andy McKeran, LR’s Chief Commercial Officer, said: "As nuclear technology advances toward maritime applications including Floating Nuclear Power Plants, global regulatory alignment is crucial. Existing frameworks must be updated to reflect modern reactor designs and operational needs. The UK has the expertise to lead these efforts at the International Maritime Organization (IMO) and with the International Atomic Energy Agency (IAEA), setting the foundation for safe, insurable, and scalable nuclear-powered shipping."

Together, CORE POWER, NorthStandard and LR aim to expand on the potential role for safe and sustainable nuclear technology within the maritime industry at the next London International Shipping Week (LISW) in September 2025.

Advanced Maritime Nuclear: A unique opportunity for the UK can be downloaded here.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Bound4Blue Installs Three Sails on an EPS Product Tanker

[By bound4blue]

bound4blue has completed the installation of its breakthrough eSAIL® suction sails on tanker vessel Pacific Sentinel with a streamlined single-stop process for Eastern Pacific Shipping (EPS) at Besiktas Shipyard in Turkey during a planned drydocking.

Three 22-metre, DNV Type Approved eSAILs® were installed on the 50,000dwt Pacific Sentinel in under a day per unit, as planned. The installation took place during a scheduled vessel drydock, with preparatory work completed in advance. The fully autonomous wind-assisted propulsion system (WAPS) will help the vessel reduce overall energy consumption with forecasted energy consumption savings of around 10% depending on vessel routing, slashing OPEX and emissions to air, while also enhancing regulatory compliance.

Fast-track, single-stop benefits

The installation heralds a landmark in numerous regards, signifying EPS’ first step into wind-assisted propulsion – as a continuation of its ambitious decarbonisation programme - while also marking bound4blue’s first tanker installation. The Spanish-based wind pioneer has undertaken a fast-track “single-stop” process, ensuring minimal vessel downtime with all work undertaken during planned vessel maintenance at the shipyard.

The fast-track, single-stop installation combined vessel groundwork, such as fitting pedestals for the eSAILs® and welding, with the simultaneous preparation and programming of the sails. This efficient approach helped minimize installation time.

David Ferrer, Co-founder and CTO, bound4blue explains:

“We’re committed to helping shipping companies, such as EPS, embrace clean, proven, wind power in the simplest, most cost efficient and effective manner. Thanks to our collaboration with shipowners, operators, shipyards, and other key partners in all installations carried out by bound4blue, we have achieved a quick, robust, and high-quality deployment procedure. In this case the vessel and sails were fully prepared in advance, ensuring they could be lifted and bolted into place without extending the planned time at the yard.”

Easy advantages

Ferrer adds that the nature of the eSAIL® unlocks further advantages for cost, weight savings and efficiency on what could otherwise have been a demanding task:

“The fact that this is an MR Tanker creates unique challenges in terms of ATEX zones and air draft limitations, but the eSAILs® simplicity is the ideal solution.

“It allows for non-EX-proof units, which streamlines the process, and reduces CAPEX, while their high performance achieves substantial savings without requiring excessively large sails, eliminating the need for tilting mechanisms and allowing for compatibility with the vessel's existing air draft. It is, we believe, an ‘easy’ way for such vessels, and many other demanding shipping segments, to access the compelling commercial, regulatory and environmental advantages of wind power.”

Ensuring regulatory compliance

The installation was also completed in collaboration with the American Bureau of Shipping (ABS), ensuring compliance with the highest classification and safety standards. Achieving a ‘wind-assisted’ notation played a key role in verifying the structural integration of the eSAILs® with the vessel while aligning with regulatory frameworks such as the EU ETS, CII, and FuelEU Maritime.

Sustainable partnerships

bound4blue has installed its solution on five vessels, with many more in its growing order book. EPS, which signed the agreement for the Pacific Sentinel in February 2024 and has now successfully completed this installation, further extended its collaboration with bound4blue in December 2024 through a new agreement for the installation of three eSAILs® on an MR tanker under construction at New Times Shipbuilding in Jiangsu Province, China. This installation is scheduled for late 2025.

Speaking of the collaboration with bound4blue, Mirtcho Spassov, Decarbonisation Manager at?EPS, comments: “We are committed to reducing emissions across our fleet by embracing cutting-edge green technologies, including wind-assisted propulsion. We need the right partners to achieve meaningful impact, and we’ve found bound4blue, with their proven technology and solutions-driven approach, to be an excellent match. This successful installation is testament to our partnership, and we look forward to harnessing the benefits of wind propulsion in support of our drive to decarbonise. We look forward to completing our second installation later this year.”

Delivering progress

The eSAIL® units work by dragging air across an aerodynamic surface to generate exceptional propulsive efficiency. The technology is suitable for both newbuilds and retrofitting across the huge majority of vessel segments, including, but not limited to, Tankers, Bulkers, Ro-Ros, Cruises, Ferries, Gas Carriers, and General Cargo vessels.

eSAILs® help shipping companies simplify compliance, and achieve advantage, with regulations including EU ETS, CII and FuelEU Maritime, while offering a typical payback of less than five years.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

No comments:

Post a Comment