GAO: The Third Ford-Class Carrier Will Be Delayed for Years

First-in-class carrier USS Gerald R. Ford has completed her first full deployment and is gearing up for another, but problems with the Ford program remain, according to the Government Accountability Office (GAO).

The Ford program encountered years-long delays during the construction of the first hull. The complexities added by Ford's all-electric launch and recovery gear, as well as her electromagnetically-actuated weapons elevators, caused difficulty at the yard and long after delivery. The keel laying was held in 2009 for a 2015 delivery date, but construction cost increased by $2.8 billion and the schedule for her commissioning slipped to 2017. She was delivered incomplete, without operable weapons elevators, and did not achieve initial operational capability until December 2021. Since then she has successfully deployed overseas, and she was recognized as the best all-around ship in the Atlantic Fleet last year.

The program office has emphasized that USS Ford was a first-in-class hull, with the inherent issues that come with a first-of-a-kind vessel, and that the teething problems with her new technology were being worked out for the follow-on carriers. But in its annual assessment of defense procurement programs, GAO reports that the Navy expects significant additional delays to future hulls in the series.

Continued issues with the weapons elevators aboard second-in-class CVN 79 could put the planned July 2025 delivery date for the vessel at risk, the program office reported. And the delivery date for CVN 80, the third Ford-class, has been pushed back to May 2030 - more than two years later than the Navy expected.

The problem, according to GAO, is in the availability of materials and skilled labor. HII Newport News has "persistent shipyard workforce issues" that the program office is trying to fix by revising schedules and creating incentives for workers, GAO said.

Newport News has been trying to hire more yard employees, but it has been hard to retain people who are new to the shipbuilding industry, HII CEO Chris Kastner told defense media in April. The attrition rate for first-year new hires is so high - the Navy puts it at 50-60 percent per year - that HII is pivoting away from bringing in "green" staff and is focused on recruiting experienced personnel instead, competing with other yards for the same pool of skilled welders. Kastner acknowledged that this "means you're going to hire less and you're going to have to figure out how to get the work done."

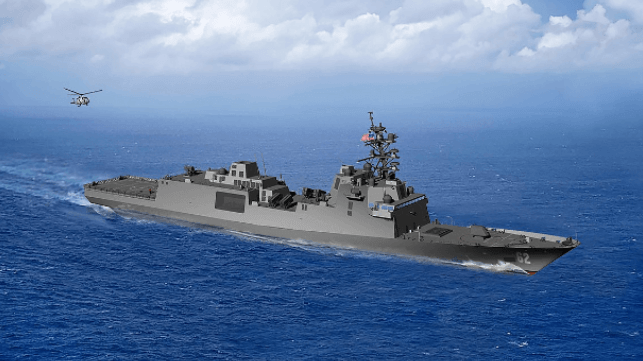

Report: Constellation-Class Frigate is Three Years Late, 13% Overweight

The Navy's Constellation-class frigate program continues to wrestle with an incomplete functional design, which has delayed construction on the first hull and may push back delivery on follow-on vessels as well, according to the GAO. At present, the lead vessel is on track to deliver three years behind schedule and an estimated 13 percent overweight.

"The Navy and shipbuilder continue to revise basic design documents, including the ship's general arrangement drawings - the design drawings that all other design aspects are based on - and structural components of the ship," reported GAO on Wednesday. "This approach is inconsistent with shipbuilding leading practices."

The Constellation-class began as an adaptation of the Italian-French FREMM, an existing design that has proven popular in Europe. Initially, the Navy sought to achieve cost savings and reduce technical risk by keeping 85 percent of the original design. Instead, it changed 85 percent of the design to adapt the vessel to Navy requirements, and it has yet to achieve design stability.

In October 2024, the Navy informed GAO that it expects to see about 759 tonnes of weight growth (13 percent) "due in part to the underestimation of applying Navy technical requirements to a foreign ship design." Weight growth can affect performance, and it limits the amount of extra equipment that can be added to the warship in future years to adapt to changing technology. The program office is working with the shipyard to reduce weight "through a phased implementation across the first three ships."

Change orders and delays tend to increase costs. So far, the shipbuilder has asked for equitable adjustment of the contract payment terms five times, GAO reports - a sign that costs will rise. The Navy has not released the amounts of the requests, and the information is "not suitable for public release," GAO reported.

No comments:

Post a Comment