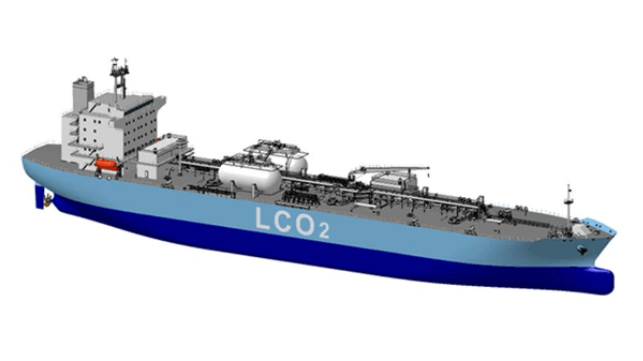

Liquefied CO2 carrier (LCO2)

Japanese Shipbuilders and Owners Team Up to Design LCO2 Carrier

The leaders in the Japanese shipbuilding industry and joining up with several of the largest Japanese shipping companies in a new effort to develop a standardized design for a liquified CO2 carrier (LCO2). The effort is designed to increase efficiency in the building of the vessels to meet the anticipated demand from the sector.

Analysts have forecast a strong and growing market for large, commercial CO2 carriers. It is part of the anticipated move for CO2 capture and reuse or sequestration. So far, just a few smaller carriers have been commissioned, although orders are expected to grow quickly in the second half of this decade.

The initiative is being conducted by MILES (Marine-design Initiative for Leading Edge Solution), a joint venture launched in 2013 by Mitsubishi Heavy Industries and Imabari Shipbuilding Co. It was originally established for the design and sales of LNG (liquefied natural gas) carriers. It was originally known as MI LNG Company, but rebranded in January 2025 to provide functional design for other emerging market segments. They said it would add work on commercial ships that use alternative fuels such as ammonia and methanol and for the design development of new liquefied CO2 carriers.

Joining in the effort, in addition to Mitsubishi Heavy Industries and Imabari, are Nihon Shipyard Co., which was already working with the group on a range of designs, and Japan Marine United Corporation. Both are also investing in MILES.

Among the shipowners and operators, NYK and Mitsui O.S.K. (MOL), and “K” Lines are also joining the initiative. All three will also be investing in MILES to accelerate the cross-industry collaboration.

The goal is to establish a standard design framework for the LCO2 carriers. According to the group, it will promote efficiency to develop and carry out the design for the initial LCO2 carriers and the next generation of alternative fuel ships. MILES will be responsible for developing the initial designs so that other shipyards in Japan will also be able to carry out the functional and production design based on the common initial designs. They aim to promote construction at multiple shipyards in Japan, utilizing the standardized design framework.

They report the initiative is expected to help Japan in regaining its global competitiveness for the shipbuilding industry.

Nihon and Mitsubishi Shipbuilding had already started joint development of new LCO2 carriers. In August 2024, the two companies, together with Kawasaki Kisen Kaisha (“K” Lin es), Mitsui O.S.K. Lines, NYK, Imabari Shipbuilding, and Japan Marine United Corporation, had also started joint studies to establish standard specifications and designs for LCO2 carriers.

Japan has used the approach of standardized designs shared among multiple shipyards successfully in other segments. The yards build standardized dry bulk carriers and have been able to maintain the market despite growing competition from China. The industry is racing to develop LCO2 carriers to meet the anticipated demand for the segment.

Meyer Werft Undocks Second Replenishment Ship for German Navy

Germany’s Meyer Werft, best known for its specialization in large cruise ships, recently undocked an unusual newbuild for the yard, a naval replenishment ship for the German Navy. The ship was part of an order that came in the aftermath of the global pandemic as an effort to use some of the excess capacity of the shipbuilder.

The 173-meter-long (576-foot) naval replenishment ship is part of a two-ship order being built in partnership with naval shipbuilder NVL (Naval Vessels Lürssen) and the Meyer Group. The contract was signed in mid-2021 between the German government and NVL as the prime contractor in cooperation with Meyer Werft. Both the Meyer Neptun yard in Rostock, which is normally used to build engine and other blocks for the cruise ships as well as the river cruise ships, and the yard in Papenburg participated in the project.

NVL, as the prime contractor, is responsible for the naval-specific components of the platform and operational systems, as well as extensive services to achieve operational readiness. Meyer took the role of manufacturing partner. The project leveraged Meyer’s construction expertise as it was responsible for building the two vessels, conducting the sea trials, and commissioning. It gave NVL, which has multiple government projects, additional building capacity while using its expertise in naval systems.

Meyer Group had been able to maintain its cruise ship orders booked prior to the pandemic, but was forced to slow production and retime some of the projects. It received its first post-pandemic order for a smaller cruise ship from Japan’s NYK in March 2021, but prospects remained uncertain for the sector. It would take till 2024 before Meyer would secure two new orders from Carnival Corporation, followed by orders from Disney and Disney’s Japanese partners. That added seven large cruise ships to the group’s orderbook as well as river cruise orders from Viking, but Meyer also required government support to maintain financial solvency.

Work on the two ships was split between the yards in Papenburg and Rostock with NVL as the prime contractor (Meyer)

Work on the first of the two replenishment oilers began in June 2023, and the first block was laid in August. Steel cutting for the second vessel began in February 2024, with its keel block laid in April. The yard in Papenburg built blocks, including the deckhouse and replenishment system, which were assembled at Neptun Werft. The first vessel was assembled in Rostock, while the forward section of the second vessel was towed in March 2025 to the Papenburg yard for completion.

NVL highlights the advanced design for the vessels. The ships are 20,000 tons displacement with a double hull design and a capacity for 13,000 cubic meters of diesel fuel. They were also designed to be able to service vessels from each side, meaning that two or even three naval vessels can be serviced simultaneously.

Another unique feature of the vessels is the numerous modular container slots. This can be used to transport food and spare parts. Also designed to support emergency operations, there is direct access from the flight deck to the sickbay for life-saving rescue operations.

Each vessel will have a normal complement of 42 sailors. However, they are designed at peak times to embark an additional contingent of 23 sailors.

The ships are replacing the older Rh?n class. The German Navy commissioned the previous two replenishment vessels in 1977. Their replacements are part of a larger program by the German government to modernize and expand its naval capabilities.

Hyundai Completes Consolidation of Ulsan Shipbuilding Yards

South Korea’s Hyundai Heavy Industries reports it has completed the consolidation of its shipbuilding operations located in Ulsan, South Korea, as of December 1. The company previously operated Hyundai Heavy Industries as the largest builder in the group, with the smaller Hyundai Mipo as a mid-sized builder. The company also owns a third shipbuilder, Hyundai Samho, which remains independent.

The group announced the consolidation plan in August. They said the move will support the growth of the shipbuilding operations. The restructuring was also undertaken in response to the global trend of ship orders being consolidated around large shipbuilders. Management pointed to the moves in China, which reorganized China State Shipbuilding Corporation, and in Japan, where the large operations are also consolidating.

As China and Japan accelerated their restructuring of the shipbuilding sector, South Korea and Hyundai are also seeking to reinforce their shipbuilding competitiveness. Hyundai has expanded its operations into the Philippines and is seeking international shipbuilding capabilities. It has already launched partnerships in the United States with HII for naval shipping and with Edison Chouest Offshore for containerships.

Under the consolidation, HHI and the Mipo yard will share more resources and management. The company reports the strategy is to maximize synergies by unifying the design operations, research and development, and production capabilities. The focus will continue to be on developing new high-value ships and areas, including eco-friendly vessels and next-generation technologies.

The company highlighted that its goal is to grow shipbuilding sales to $25 billion annually. A key part of this strategy calls for a 10-fold increase in defense and warship sales. Hyundai Heavy Industries set a goal of achieving $6.8 billion in annual defense-related sales. The company won its first maintenance and repair contract from the United States this year for an auxiliary ship supporting the U.S. Navy.

Hyundai Heavy Industries expects the integrated operations will also play a key role in the Make American Shipbuilding Great Again (MASGA) promise by the South Korean government during trade negotiations with the United States. South Korea committed to investing $150 billion into the American shipbuilding industry. It was previously reported that Hyundai was exploring the possible acquisition of a U.S. shipbuilder to expand on its relationships with the industry.

The company also highlights the opportunities in emerging sectors. This, they said, includes icebreakers and ice-capable shipping. It points to South Korea’s initiatives to develop Arctic shipping and the overall growth in the area.

Samsung Heavy Industries and Evergreen Advance Remote Ship Monitoring

Continuing to look to the future with remote ship management, shipbuilder Samsung Heavy Industries and Evergreen have opened the first remote monitoring center jointly developed by a shipyard and shipowner. It is the next step in a continuing project between the two companies that anticipates the era of remote autonomous navigation.

The Samsung Remote Operation Center was established at Evergreen’s headquarters in Taipei, Taiwan. The companies report that they plan to use the center to expand the use of technology in the areas of remote periodic inspection and prepare for remote autonomous ships.

The companies have already demonstrated the opportunities in autonomous ship management and the use of AI to manage a vessel. The yard equipped the newbuild containerships for Evergreen with its Samsung Autonomous Ship technology. From August 25 to September 6, the 15,500 TEU Ever Max (160,000 dwt) was guided by an AI-based navigation system during a 10,000-km (6,200-mile) Pacific crossing. The vessel, which Samsung delivered in 2023, was designed to incorporate the new technologies.

The AI-based system demonstrated autonomous navigation optimization. The system monitored the ship’s operations and analyzed the weather and route conditions every three hours. Without crew intervention, the system performed 104 optimal guidance adjustments and automatically controlled the ship 224 times. The companies reported that the system increased fuel savings and ensured an accurate arrival time.

With the new center, they plan to conduct condition-based maintenance analysis. The center will also link to the ship’s video information for remote monitoring support.

Evergreen reports that it plans to gradually increase the number of ships that can perform efficient equipment inspection and maintenance by real-time monitoring. They expect to be able to fully monitor major equipment status from the center. They are describing the center as a land-based control tower.

The companies have agreed to expand technology development in areas such as remote periodic inspection. They also believe the center will lay the foundation for remote autonomous navigation of large vessels.

IIT Guwahati and Indian Register of Shipping Highlight Milestone

[By: Indian Register of Shipping]

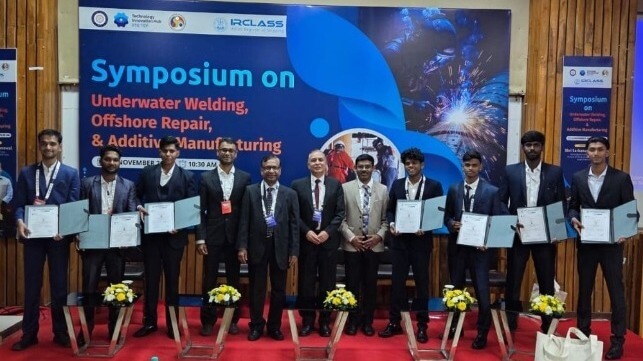

Indian Institute of Technology (IIT) Guwahati, in association with Indian Register of Shipping (IRS) announced the successful conduct of the Symposium on Underwater Welding, Offshore Repair & Additive Manufacturing held at the IIT Guwahati on 22 November 2025. The event was graced by Shri Sarbananda Sonowal, Hon’ble Minister for Ports, Shipping & Waterways, whose presence added immense significance to the occasion.

The ceremony featured the certificate distribution for the second batch of the Underwater Welding (UWW) Programme, a joint initiative of IRS and IIT Guwahati. The Underwater Welding Programme is a highly specialised and unique initiative in India, aimed at developing trained and certified professionals in an area critical to offshore repair, subsea construction, and maritime infrastructure. This pioneering programme reaffirms IRS’s commitment to supporting capability-building in emerging technical domains.

The primary goal of the programme is to develop qualified manpower capable of performing underwater welding with high precision and reliability. While acknowledging existing challenges in mastering this niche domain, IRS expressed strong confidence that these can be overcome through sustained effort, innovation, and structured training.

Dr. Asokendu Samanta Divisional Head R&D, IRS emphasised the importance of cohesive collaboration between academic institutions and industry bodies to drive national progress. “For a country to advance, academia and industry must work together seamlessly. This partnership between a premier institution like IIT Guwahati and IRS, stands as an exemplary model for developing specialised programmes of national relevance.”

Prof. Devendra Jalihal Director, IIT Guwahati said “This programme marks a meaningful step forward in strengthening India’s underwater engineering capabilities and contributes to the broader vision of ‘Atmanirbhar Bharat’ (Self-Reliant India) articulated by the Hon’ble Prime Minister”.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Lloyd’s Register Joins DCSA+ To Accelerate Digitalisation In Shipping

[By: Lloyd's Register]

By joining DCSA+, LR becomes part of a global community of carriers, shippers, terminals, forwarders and technology providers working together to align the industry behind open digital standards.

The DCSA+ programme provides a structured platform for collaboration, enabling partners to connect with peers and contribute directly to the development of practical, scalable digital solutions for the container shipping ecosystem.

As an official partner, LR will initially engage in the development of the Operational Vessel Schedules (OVS) standard, an initiative focused on improving visibility and coordination across the vessel schedule value chain.

Nick Gross, Global Container Ship Segment Director, LR, said: “Joining the DCSA positions us at the forefront of digital transformation within the containership segment. Our focus is on developing digital solutions to provide greater operational efficiency, which are dependable and scalable. Partnering with DCSA members enables us to combine our technical expertise with real-world insight, helping to shape common standards and practical solutions to make data more accessible, reliable and useful for all stakeholders in the containership value chain.”

Mariana Bock-Losada, Chief Growth Officer at DCSA, said: “Lloyd’s Register adds valuable technical and operational depth to the DCSA+ community. Their involvement reinforces our joint ambition to accelerate the adoption of digital standards across container shipping and to build a more connected, efficient, and sustainable industry.”

Jeremy Daoust, Head of Market Management & Insights, OneOcean added: “OneOcean has a long history of connecting ships, fleets and people to deliver clarity and foresight through a digital ecosystem. Our solutions cover navigation, compliance, ESG and decision support for more than 30,000 vessels, serving over 1 million seafarers. As such, we look forward to working closely with the DCSA, to share our expertise, and help maritime leaders run safer, smarter, more sustainable operations across the value chain.”

DCSA+ extends DCSA’s work beyond carriers to the wider ecosystem, enabling technology providers and other partners to play an active role in building the standards that power global trade.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

No comments:

Post a Comment