ALT. FUEL

New Svitzer Tug is First to Integrate Battery with Methanol Fueled Engines

A new tug construction project underway at Turkey’s Uzmar shipyard will integrate a marine battery power system with a methanol-fueled engine to minimize emissions from the operations. The vessel is being built for Svitzer and will be launched later this year for operations in Gothenburg, Sweden.

The tug is based on Svitzer’s TRAnsverse tug design and will be used for escort duty. With a gross tonnage of approximately 806 tonnes, the tug will be capable of achieving speeds of up to 14 knots. Delivery is planned in the second half of 2025.

The order for the 6MWh battery went to AYK Energy and is its first contract with Uzmar. The battery will be built at the company’s new facility in Zhuhai, China, and delivered to Uzmar for installation in the tug. AYK attests to having the highest energy density and volumetric density in the industry today. Combined with its Battery Management System) and packaging solution, it reports it has tailored unique solutions for the maritime sector. It claims to offer the safest, lightest, most affordable, easiest to operate, and commission battery with the ability to operate in smaller spaces.

"Battery solutions are constantly expanding, and we are proud to be at the forefront when it comes to providing those solutions to the maritime sector,” said AYK Energy founder Chris Kruger, He said the contract “shows our continuing progress in winning the bigger battery projects.”

The battery power system will be supported for the first time by dual-fuel methanol engines. The engines will be used for backup power and to extend the range of the tug. However, according to the companies, they expect the tug to perform more than 90 percent of its escort duty operations using its battery-electric powertrain. They said the vessel’s design will also allow the battery-powered tug to operate more efficiently than internal combustion engine-powered tugs of a traditional design.

Uzmar says that the combination of battery power and methanol engines will provide a safe, efficient, and reliable solution.

“The launch of a first-of-its-kind newbuild project with our partners at Uzmar Shipyard is a significant milestone for our decarbonization ambitions,” said Gareth Prowse, Head of Decarbonization at Svitzer. The battery electric tug will mean we can deliver our services to customers in the Port of Gothenburg with significantly lower carbon emissions, and still to the highest operational and safety standards.”

Companies such as Svitzer see battery power as becoming an important option in the sustainability transition. Marine batteries are demonstrating that they can play a fundamental role in decarbonizing the industry, as an increasing number of tugs are being built and deployed with battery-electric powertrains.

Odfjell Completes Install of First Sails on Tanker to Analyze Fuel Savings

Global chemical tanker operator Odfjell has joined the growing list of shipping companies that are incorporating wind-assisted propulsion into their operations as they seek to lower emissions. The company’s first sail installation was completed in Antwerp, and the chemical tanker Bow Olympus will now be carefully monitored to observe the impact on operations.

“The five-year-old vessel will soon embark on what could be called her second maiden voyage—this time, crossing the Atlantic towards Texas with four eSails," said Erik Hjortland, VP Technology for Odfjell. “Each nautical mile will be thoroughly analyzed in real-time to document the energy-saving effects. That data will be fundamental in informing future decisions as we continue to improve the environmental performance of our existing fleet.”

Odfjell selected bound4blue’s eSails, a wind foil that it said is best suited to the challenges of chemical tankers. They noted that the deck of the vessel is covered in pipes for multiple cargo tanks. The integration of the sail foundations required careful planning to ensure a seamless fit with tanker operations and the vessel’s requirement for air draft limitations.

Bound4blue says that it was able to minimize the size and eliminate the need for tilting systems because its eSails generate six to seven times the propulsive lift of equivalently proportioned rigid sails. The fully automated eSails generate propulsive force by dragging air across an optimized aerodynamic profile. The Bow Olympus which is approximately 600 feet (183 meters) and 49,000 dwt, was fitted with four 72-foot (22-meter) eSails.

To accommodate the vessel’s operating schedule, the installation was undertaken in two stages. The foundations were fitted during a scheduled drydocking. The sails were installed during two days, March 10 and 11, at the EDR Antwerp Shipyard.

“We’ve made some major steps in minimizing our emissions, reducing our fleet’s carbon intensity by 53% against the 2008 baseline,” says Hjortland. “We’ve done this through many operational measures and by installing a range of different energy-saving devices. Wind power was the next step.”

This project is funded by the European Union under a grant agreement from the Innovation Fund program. The tanker company says once results are validated from the operation of this first vessel, the plan is to install sails on more of its vessels.

Odfjell joins owners such as Amasus, Eastern Pacific Shipping, and Louis Dreyfus Armateurs with operational eSAILs. David Ferrer, Co-Founder and CTO of bound4blue notes that other major shipping companies such as Maersk Tankers, Marflet Marine, and Klaveness Combination Carriers are filling the company’s growing orderbook.

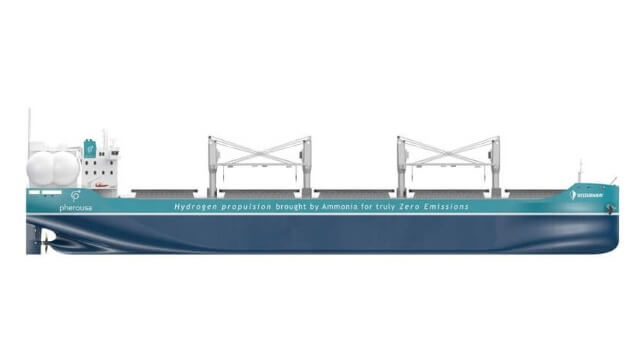

Class Societies ABS and DNV Advance Plans for Ammonia-Cracking Bulker

An innovative project to develop a shipboard ammonia-cracking technology took a key step forward toward the vision of building a zero-emission dry bulk carrier for the copper industry. Class societies ABS and DNV working with Norway-based Pherousa Shipping and technology company Metacon have issued design Approval in Principle reporting they found “no show stopper conditions” to employing the innovative technology.

Ammonia continues to draw interest with systems in development but so far it has required carbon fuel primers to start ignition and presents the challenges of lower energy density versus traditional fuels. Hydrogen similarly shows potential as a power source but so far has been limited to small near-shore support vessels and inland shipping.

“The Approval in Principle from two of the leading classification societies and certification bodies, ABS and DNV, marks another important milestone for us in the development of zero-emission solutions for the maritime industry,” said Hans Bredrup, Chairman of Pherousa. “By granting Pherousa these AiPs, both ABS and DNV clearly state that there are no showstoppers of the Pherousa technology for marine application.”

Pherousa’s concept working with an exclusive license agreement from Metacon for the application of the technology onboard ships focuses on developing ammonia cracking, the release of hydrogen energy from ammonia as a carrier, at scale to power larger vessels. The ammonia cracking technology would be used with PEM Fuel Cells and a Fuel Gas Supply System generating a fully electrical propulsion plant.

“Ammonia cracking combined with a PEM Fuel Cell has no need for pilot fuel or other fossil sources,” explains Morten Løvstad, VP and Global Business Director for Bulk Carriers at DNV. He called it, “an innovative solution for maritime application towards full decarbonization.”

Pherousa reports that Ammonia Cracking can be applied to a variety of developed technologies, such as supplying Hydrogen to PEM Fuel Cells, replacing conventional fuels with Hydrogen as pilot fuel on Ammonia fueled Internal Combustion Engines, or supplying Hydrogen Internal Combustion Engines. It could also be used for supplying Hydrogen to Auxiliary Engines to reduce emissions. According to the company, any of the four alternatives can be fitted onboard any type of vessel and with an engine power of up to 15-20 MW.

“The efficiency of ammonia cracking will play a decisive factor in its ability to contribute to decarbonization of the industry,” predicts Stergios Stamopoulos, Director, Global Sustainability for

American Bureau of Shipping (ABS).

Pherousa and Metacon report that have conducted thorough research and tests to develop the Ammonia Cracking technology concept. The companies have delivered a working prototype that demonstrated the practical potential of this approach.

The Pherousa subsidiary, Pherousa Shipping, reports it has worked closely with two major copper miners during the design process of an Ultramax 64.000 dwt vessel, to find the optimal layout for emission-free transportation of copper concentrates between its origin and the smelters. The vessels are intended to be on water in parallel with the new IMO regulative that comes into force in 2030.

They are focusing on the copper industry because the commodity is essential for emerging markets linked to decarbonization. They believe end-users of copper utilized for solar panels or electric cars will seek to build a carbon-free supply chain including shipping.

Having achieved the design reviews from ABS and DNV, Pherousa reports it is now transitioning from concept to scale-up and market entry. It looks to deploy its innovative solution on a global scale.

No comments:

Post a Comment