ALT. FUELS

Project Outlines Process for Converting Standard Bulk Carrier to Methanol

A new project led by the Maersk Mc-Kinney Møller Center for Zero Carbon Shipping addressed the challenges and processes required to convert one of the largest segments of the current global shipping fleet, the Kamsarmax bulk carrier, for dual-fuel methanol operations. With involvements from leaders across the segments of the industry, the project leaders believe it is a key step in decarbonization that provides critical insights into the feasibility of retrofit projects.

The project, which aimed to assess the techno-economic feasibility of a retrofit from fuel oil to dual-fuel methanol, has been granted an Approval in Principle (AiP) by Japan’s ClassNK, which also contributed regulatory advice and facilitated safety risk assessments.

The Center highlights that Kamsarmax bulk carriers represent a significant share of the existing fleet. It believes that developing a general retrofit package could drive low-emission solutions across the maritime industry. Additionally, the project sheds light on the challenges and opportunities that need to be addressed when deciding to retrofit a bulk carrier.

The retrofit project was based on a standard Kamsarmax design developed by Tsuneishi Shipbuilding which worked along the Center as a lead in the project. They explored the technical and operational challenges and opportunities of converting vessels to dual-fuel methanol. The retrofit design and technological solutions were developed in close cooperation with MAN ES, which provided the main engine and FuelTech expertise on design reviews and HAZID processes (Hazard Identification). Cargill offered operational and technical insights bringing in the charterer’s perspective, while the Danish Maritime Administration participated as an observer.

“With the medium-sized bulk carrier segment representing a substantial share of the industry, this modular retrofit solution paves the way for an accelerated transition to methanol and other sustainable fuels,” said Evangelos Fragkoulis, Head of Ship Design for the Maersk Mc-Kinney Møller Center for Zero Carbon Shipping. “It demonstrates a paradigm shift towards non-intrusive, safe, and agile solutions that enable the integration of green fuels without compromising safety.”

The Kamsarmax is an 80,000 to 84,000 dwt dry bulk carrier which is very popular in the industry with the first vessel of the class delivered in 2005. Tsuneishi alone reports having built over 300 of the vessels, and the number one market share in the category, which generally measure approximately 230 meters (755 feet) in length making it a versatile and economical design. Tsuneishi highlights with a lifespan of 20 to 30 years, it is a critical segment of the industry that will significantly impact maritime decarbonization efforts.

The project generated multiple design solutions, including novel and modular fuel handling onboard, as well as methanol storage and integration options that optimize safety, capacity and ultimately reduce cost and conversion lead times. Additionally, the project has developed general design principles for methanol retrofit aimed at ship designers, shipyards and operators, providing a navigational framework through key design decisions.

The Maersk Mc-Kinney Møller Center for Zero Carbon Shipping reports that it will be releasing a comprehensive case study on the design. The guidelines developed during the project will also be released late this year.

ENEOS Joins Maersk and APM Investing $100M in U.S. Green Methanol Project

Japan’s leading energy company ENEOS is joining with A.P. Moller Holding and A.P. Moller – Maersk investing $100 million in C2X, the green methanol developer launched in 2023 by A.P. Moller Holding. The proceeds will primarily be used to fund the final development of a Louisiana project to produce green methanol as well as to advance C2X’s current efforts in the U.S., Spain, and Egypt to build green methanol production for the shipping, aviation, and chemical sectors.

C2X reports the investment is a critical step to advance the development of the Beaver Lake Renewable Energy project in Louisiana to FID, which is being developed with SunGas Renewables. The project will use SunGas’ S-1000 gasification technology system to convert biomass into low-carbon methanol. The project will also capture and permanently sequester approximately 1 million tonnes per year of surplus biogenic CO2 from the gasification process, generating carbon dioxide removal (CDR) credits.

The multibillion-dollar project aims to start construction in the second half of 2026. Once operational, which is targeted for the end of 2028, it will produce over 500,000 tonnes of green methanol annually. C2X reports it is also in discussions to secure long-term offtake agreements from Maersk and other customers in its targeted shipping, chemicals, and industrial sectors.

The Beaver Lake facility is the first of several facilities planned by SunGas and C2X to supply green methanol. It would repurpose a former International Paper site in Rapides Parish, Louisiana that closed in 2009. SunGas has estimated the facility would be valued at $2.4 billion.

SunGas and C2X announced a strategic partnership and C2X’s investment in SunGas in May 2024. ENEOS’ new investment is accompanied by a strategic partnership with C2X, which considers methanol offtake and the application of SunGas’ gasification technology into its system portfolio.

AP Moller launched C2X to help expedite the process of developing a global production and supply chain for methanol. The company has previously announced projects in Spain, Egypt, and the United States. With the new commitment from ENEOS, Maersk, and APM, it looks to continue to accelerate the development of its portfolio of projects.

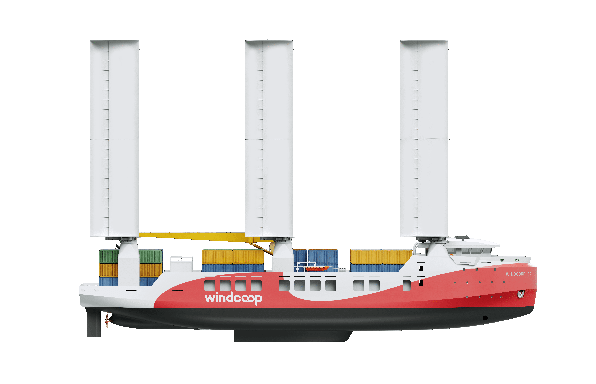

Construction Order Placed for World’s First Sail-Powered Containership

The French cooperative Windcoop completed the construction order for its revolutionary open-hatch sail-powered cargo ship, the first of what the group envisions will be a pioneering fleet of ships. The order was placed with Turkey’s RMK Marine, which is also building the sail-powered RoRo Neoliner Origin.

The group reports it has had to overcome major technical and logistic challenges to integrate a wind-powered propulsion system while also ensuring efficient container handling. This was in part solved with asymmetrical sails, the open-hatch design, and the placement of cranes on the opposite from the sails. It helps to provide stability and balance while also giving the vessel total autonomy for loading and unloading.

The vessel will be 91.3 meters (approximately 300 feet) in length with a capacity for 210 TEU and 40 reefer plugs. The three wingsails designed by Computer Wingsails (CWS) are each 350 square meters (approximately 3,800 square feet) or a total sail area of 1,050 square meters (11,300 square feet). The vessel is projected to have an average sailing speed of 9 knots.

“After four years of development, we are finally taking decisive steps toward realizing what was once considered an audacious dream,” said Matthieu Brunet, Chairman of Windcoop. The effort was started in 2022. Based in Lorient, France, Windcoop was created through the collaboration of Zéphyr & Borée, Enercoop and Arcadie.

The project with RMK calls for orders to the subcontractors including the sails and engines and finalization of the studies and tank tests for the vessel this year. Construction is due to begin in 2026 and trials, delivery, and commissioning in May 2027.

The total construction cost is set at €28.5 million ($31.5 million). Windcoop reports it has secured financing of €28.5 million structured by Crédit Maritime Grand Ouest – Banque Populaire, with a counter-guarantee from Bpifrance. The financing includes €6.8 million ($7.5 million) raised through the cooperative. This involved 1,600 citizens, committed shippers (Arcadie, Valrhona, Prova, Lobodis, Ethicable, Cafés Richard, Demad, Arawak), and institutional investors (La Nef, Crédit Mutuel Arkéa, SIDI, Mer Invest, Inddigo, Bretagne Capital Solidaire). It is the first cargo ship of this size to include cooperative funding.

The first service route was selected to focus on secondary ports that are traditionally neglected because they lack the capacity or equipment to load goods. The group says it aims to “rebalance the logistics network” while also reducing carbon emissions by limiting land transport. The vessel will be registered in France and sail a route between France and Madagascar, connecting Marseille to the ports of Tamatave, Diego Suarez, and Majunga, without transshipment and including transits of the Suez Canal. They project a transit time of 31 days.

From Madagascar, they will carry cargo including aquaculture, cocoa, vanilla, spices, essential oils, and textiles. While they expect to export from France to Madagascar retail goods, glassware, paramedical products, and textiles.

Windcoop has ambitious plans. It aims to secure financing and rapidly build a second vessel to ensure a monthly service on the Madagascar-France route. At the same time, Windcoop plans to expand its fleet by launching new maritime routes designed to meet the needs of the shippers and the territories involved. A regional line in the Indian Ocean, a transatlantic connection as well as a direct link to West Africa are currently in the planning stages.

No comments:

Post a Comment