[By: Taiwan International Ports Corporation]

Established in 2012 by the Ministry of Transportation and Communications ROC, Taiwan International Ports Corporation (TIPC) is in charge of seven international ports in Keelung, Taipei, Suao, Taichung, Kaohsiung, Anping, Hualien, and operates two domestic commercial ports in Budai and Penghu.

TIPC’s main business includes specializing in international commercial port management, container and bulk cargo loading and unloading, freight warehousing, international cruise terminals and other core port businesses. In line with international port management trends, TIPC seeks to diversify business scope through asset development, reinvestment, and international expansion.

TIPC has actively developed investment businesses since 2014 and now holds more than 20% of the equity in a total of 7 investment affiliates and subsidiaries, focusing on the main port industry such as harbor towage service, warehousing & logistics, land development around the port area to create higher economic value.

In addition, in accordance with offshore wind power policies, TIPC has developed offshore wind power related business such as “O&M”, “logistics & warehousing” “wind power talent cultivation”, and “heavy cargo transportation”.

Meanwhile, in response to government’s New Southbound Policy and TIPC’s investment strategy, TIPC has worked with affiliates to explore countries in Southeast Asia with economic development potential and cargo sources, and deployed port-related and extended industries in ports, logistics and terminals in order to promote the diversified development.

Outreach core competencies of port business and capacity

Working Vessels & Operations and Maintenance

Founded in 2014, TIPC Marine Corporation (TIPM) is TIPC 100% subsidiary. The main business projects are shipping related services in commercial port areas such as vessel entry and exit and berthing operations, and high-quality ship repair services.

TIPM has provided vessels and onshore facility services for major offshore wind developers and EPCI (Engineering, Procurement, Construction, and Installation) companies, earning recognition for its high service quality since 2017.

The fleets of TIPM include CTVs, tugs, and barges. TIPM has participated in the construction of most offshore wind farms in Taiwan, providing personnel transportation, heavy cargo transport, guard vessel services and onshore facility leasing.

Notably, TIPM has built long-term partnership and project collaboration with offshore wind developer. Additionally, TIPM manages Taiwan's largest offshore wind O&M base at Taichung Port to form the industrial cluster.

Heavy Cargo Transportation

Taiwan International Ports Heavy-Machinery Corporation (TIPH), established in 2020 as a joint venture between TIPC and Giant Heavy Machinery Service Corporation, specializes in heavy cargo transportation and offshore wind project management.

TIPH offers customized logistics planning, construction method design, and equipment support, including cargo-specific assessments, lifting and transport equipment configuration, and route planning — all delivered through an integrated approach to ensure high safety and execution quality.

TIPH has actively participated in numerous Taiwan’s offshore wind farm projects to transport key components such as pin piles, jackets, blades, towers, and nacelles.

TIPH will take a more proactive role in clean energy industry projects in the future.

With abundant experience and strong execution capability, TIPH is dedicated to becoming the hub for heavy cargo transportation and port engineering in the Asia-Pacific region.

Logistics Services

Taiwan International Ports Logistics Corporation (TIPL), as a joint venture between TIPC and 3 private enterprises, was established in 2014.

TIPL operates warehousing and logistics businesses in Kaohsiung, Taichung and Taipei Ports, with leased warehouses located in the Free Trade Zone. TIPL takes advantage of the Free Trade Zone to mainly provide various high value-added logistics services.

TIPL operates “Maritime Cargo Express Service” in Taipei Ports for the demand of goods in real time and small quantities. The service provides fast and efficient logistics solution for cross-border logistics in the Asia region.

In recent years, to meet the demand of offshore wind energy industry, TIPL has been actively seeking offshore wind energy business opportunities since 2021, and provide indoor/ outdoor storage area at Taichung Port for offshore wind farm O&M parts storage.

The end customers include offshore wind energy developers and equipment suppliers. In the future, TIPL will also seek to become an O&M Base of offshore wind energy operator.

Waterfront Development

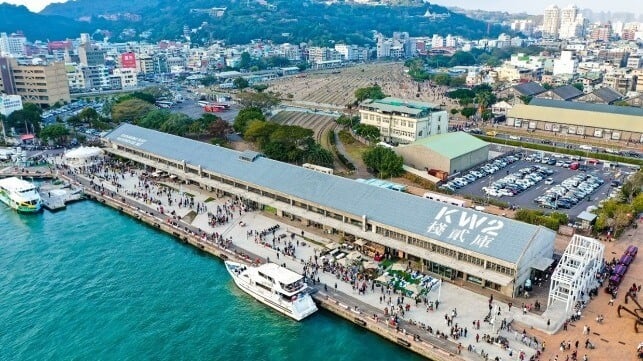

Kaohsiung Port Land Development Corporation (KPLD) was established in 2017.

The main business services are to promote the development of the old port areas of Kaohsiung Port and the surrounding areas, and combine the resources and platforms of TIPC and Kaohsiung City Government to achieve the goals and benefits of regional development.

Nowadays, KW2 and Kaohsiung Port Depot have been iconic landmarks in Kaohsiung city. With the collaboration of port and city, KPLD demonstrates successfully resilience of ports from cargo transportation to waterfront recreation.

Bridging Asia Pacific Region

New South Bound

TIPC actively promotes internationalization and expands overseas investment business in line with the government's New Southbound Policy. PT. Formosa Sejati Logistics (FSL) and Taiwan Foundation International Pte. Ltd (TFI) were established in 2018.

FSL mainly operates container distribution and logistics warehousing in Surabaya, Indonesia, and also provides container consolidation, container maintenance, inland and ocean freight, and third-party logistics operations (integrated logistics).

TIPC sets up TFI in Singapore by cooperating with domestic shipping, port and logistics business operators, in order to evaluate suitable targets in Southeast Asiancountries to carry out investment planning and management business in ports, international logistics and other industries.

Talent Cultivation

Founded in 2018, Taiwan International Windpower Training Co., Ltd. (TIWTC) is a joint venture between TIPC and several state-owned and private enterprises affiliated with the offshore wind industry.

TIWTC is committed to cultivating offshore wind professionals who meet international standards. As one of the largest offshore wind training centers in the Asia-Pacific region, TIWTC operates advanced training facilities and delivers safety and technical training modules accredited by the Global Wind Organization (GWO).

TIWTC also offers Dynamic Positioning (DP) courses certified by the Nautical Institute (NI), providing a broad range of specialized maritime training programs.

Training more than 1,000 participants annually, TIWTC has successfully cultivated over 10,000 offshore wind professionals to date. It has held the highest number of GWO certifications in Asia for four consecutive years and was honored with the GWO “Training Team of the Year – Asia Pacific” award in 2024, in recognition of outstanding training performance on the international stage.

In 2025, TIWTC was nominated for the fifth time as the GWO “Training Team of the Year – Asia Pacific. In 2024, TIWTC established a subsidiary in Japan, further strengthening regional presence and reinforcing role as a key connector of global offshore wind talent.

Future Prospects

TIPC aims to become a world-leading port management group. Due to the changes and increasingly intense competition in the international port ecosystem, in order to overcome the challenge in its core business, TIPC draws on the experience of international benchmark port groups to enhance corporate value and competitiveness through diversification and conglomeration.

The products and services herein described in this press release are not endorsed by The Maritime Executive.