By M. V. Ramana | June 20, 2022

Bulletin of the Atomic Scientists

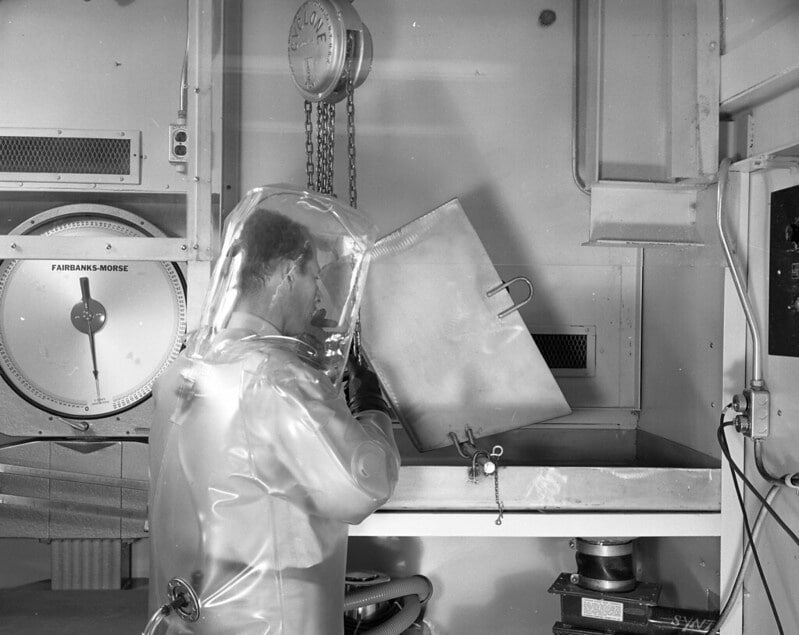

A technician prepares salts for use in MSRE in 1964. By Oak Ridge National Laboratory. Accessed via Flickr. CC BY 2.0.

Molten salt nuclear reactors are all the rage among some nuclear power enthusiasts. They promise designs that will soon lower emissions from shipping, be cheaper to run and consume nuclear waste, and be transportable in shipping containers. The Canadian government has provided two companies, Terrestrial Energy and Moltex, with tens of millions of dollars in funding. Indonesia’s Ministry of Defense has sponsored a study of thorium-based molten salt reactors. The International Atomic Energy Agency organized a webinar calling molten salt reactors “A game changer in the nuclear industry.” Unsurprisingly, China has plans to build one.

Molten salt nuclear reactors are all the rage among some nuclear power enthusiasts. They promise designs that will soon lower emissions from shipping, be cheaper to run and consume nuclear waste, and be transportable in shipping containers. The Canadian government has provided two companies, Terrestrial Energy and Moltex, with tens of millions of dollars in funding. Indonesia’s Ministry of Defense has sponsored a study of thorium-based molten salt reactors. The International Atomic Energy Agency organized a webinar calling molten salt reactors “A game changer in the nuclear industry.” Unsurprisingly, China has plans to build one.

MSRE Molten Salt Reactor Oak Ridge National Lab. Oak Ridge Tennessee 2003. DOE photo by Lynn Freeny. US government photo accessed via Flickr.

Unlike other nuclear reactor designs that can claim multiple roots, the technology underlying molten salt reactors has a fairly clear origin: the Oak Ridge National Laboratory in Tennessee. All molten salt reactors are based, in one way or another, on the Molten Salt Reactor Experiment that operated at Oak Ridge from 1965 to 1969. That experimental reactor, in turn, was based on another experimental reactor, the Aircraft Reactor Experiment, that had operated a decade earlier at the same facility.

Among developers, the Molten Salt Reactor Experiment has a legendary status. For example, in 2015, an official from Terrapower, the nuclear venture funded in part by Bill Gates, noted that his company was “excited to celebrate and build upon” the experiment by designing a molten chloride fast reactor. His accompanying slide show reinforced the message with pictures of the Molten Salt Reactor Experiment assembly, the red hot heat exchanger, and Alvin Weinberg, the leader of Oak Ridge at that time, noting that the experiment had operated for 6,000 hours. Also in 2015, Terrestrial Energy’s David LeBlanc made “a kind of pilgrimage to Oak Ridge” to celebrate the 50th anniversary of the Molten Salt Reactor Experiment becoming critical.

Many molten salt reactor developers and proponents seem to have decided that the Molten Salt Reactor Experiment experience was so successful that all that remains is for it to be scaled up and deployed across the world. But is this really the case? A careful look suggests otherwise.

Molten salt reactors’ early history. Molten salt reactors go back to the US Air Force’s failed effort to build a nuclear-powered, long-range bomber aircraft. The Air Force spent more than $1 billion (over $7 billion in today’s dollars) between 1946 and 1961 on its Aircraft Nuclear Propulsion program. President John F. Kennedy, seeing how little had been achieved, told Congress on March 28, 1961 that the possibility of success in the foreseeable future was “still very remote” and recommended terminating the program.

As part of this effort, the Air Force made Oak Ridge National Laboratory responsible for building the Aircraft Reactor Experiment as part of its effort to fly a bomber on nuclear power. The 2.5 megawatt reactor operated for a mere nine days in November 1954. Some Oak Ridge officials considered running the reactor longer, but others grew concerned about overheating of one of the reactor components. That concern was legitimate; five days later, this component failed and “released radioactive gas into the reactor compartment.” But Oak Ridge National Lab officials were undeterred. For them, the experience showed “the feasibility of molten-salt fuel” and they “persuaded the Atomic Energy Commission to fund a study of molten-salt power reactors.” In 1958, the commission did just that, and thus began the Molten Salt Reactor Experiment.

To understand the interest in molten salt reactors, start by adopting a 1950s mindset. At the time, nuclear power was expected to expand rapidly, and some energy planners were worried that there would be insufficient uranium to fuel all the reactors to be built over upcoming decades. Alvin Weinberg, the head of Oak Ridge, expressed this eloquently when he prophesized that humanity would need to “burn the rocks” in what are called breeder reactors in order to live a “passably abundant life.” While the dominant types of reactors around the world (light water reactors and heavy water reactors) use only a small fraction of the uranium and thorium found in the Earth’s crust, breeder reactors can exploit a much larger fraction of these minerals.

The concern among nuclear power advocates about running out of uranium was also at the heart of another major nuclear development during this period: the liquid metal (sodium) cooled fast breeder reactor. These reactors were an effort to tap the energy present in the uranium-238 isotope that is not used in standard light and heavy water reactors by converting it into plutonium. Glenn Seaborg, who discovered the element and rose to become Chairman of the US Atomic Energy Commission from 1961 to 1971, predicted in 1970 that, by the year 2000, plutonium “can be expected to be a predominant energy source in our lives.” By contrast, the molten salt reactors were mostly intended as a pathway to use thorium, which was more plentiful than uranium, by converting it into uranium-233.

In retrospect, these expectations proved mistaken in three ways. First, energy demand has risen much more slowly, both in the United States and globally, than predicted. For example, in 1959, Weinberg assumed that the global population would stabilize at 7 billion and that it would need at least 1.9 billion, billion BTU per year. In comparison, in 2020, the world used a little over a quarter of this level of energy for nearly 8 billion people.

Second, nuclear energy proved much more expensive than envisioned in the heady “too cheap to meter” era. As nuclear power’s poor economics became apparent, reactor construction declined dramatically and has never achieved anywhere near the levels seen in the 1970s and 1980s. (Accidents at Three Mile Island and Chernobyl only reinforced this trend.) The United States illustrates the drastic difference between expectation and reality. The Atomic Energy Commission projected that US nuclear power generating capacity in 2000 would be 1.1 million megawatts (or 1,100 gigawatts). In fact, US nuclear capacity only reached a maximum of 101 gigawatts, and it has since declined to less than 95 gigawatts as of June 2022 (after the Palisades reactor was shut down). Globally, nuclear energy’s share of electricity generation has sunk from a maximum of 17.5 percent in 1996 to just over 10 percent in 2020.

Third, uranium proved to be more ubiquitous than anticipated, and global uranium resource estimates have continuously increased. The International Atomic Energy Agency and the Organization for Economic Co-operation and Development’s Nuclear Energy Agency calculate that the world’s resources of cheaply available uranium ore are adequate to fuel the global reactor fleet, even in the event of an increase in nuclear power generation.

All of these realizations were, of course, only to be had in the future. In the 1950s, when the molten salt reactor programs were actively pursued, there was an air of urgency. This urgency was reflected in the break-neck speed with which the Molten Salt Reactor Experiment, Oak Ridge’s proposal for the next step in the molten salt reactor research process, was designed and constructed. As one of the Oak Ridge team leaders described it, “Design of the [Molten Salt Reactor Experiment] started in the summer of 1960, and construction started 18 months later, at the beginning of 1962. The reactor went critical in June 1965.”

In 1965, when the reactor started operating, it was fueled by a mixture of 150 kilograms of depleted uranium and 90 kilograms of weapons-grade, highly-enriched uranium (93 percent of uranium-235). After March 1968, the fuel was changed to one involving another weapons-usable material, uranium-233, which was derived from thorium. After this switch, the Molten Salt Reactor Experiment went critical in October 1968 and reached full power in January 1969. But at the end of that year, the experiment shut down. No more molten salt reactors have been built since.

The Molten Salt Reactor Experiment operation. Proponents of molten salt reactors have claimed for decades that the Molten Salt Reactor Experiment operated successfully. Indeed, they started making this claim even when it had barely started operating. In May 1966, for example, Paul Haubenreich, Oak Ridge National Laboratory associate director, cockily announced that the experiment “will live up to the name which we think goes with the initials M.S.R.E.—Mighty Smooth Running Experiment.” This, after listing many problems, including a basic one that was never resolved.

Unlike other nuclear reactor designs that can claim multiple roots, the technology underlying molten salt reactors has a fairly clear origin: the Oak Ridge National Laboratory in Tennessee. All molten salt reactors are based, in one way or another, on the Molten Salt Reactor Experiment that operated at Oak Ridge from 1965 to 1969. That experimental reactor, in turn, was based on another experimental reactor, the Aircraft Reactor Experiment, that had operated a decade earlier at the same facility.

Among developers, the Molten Salt Reactor Experiment has a legendary status. For example, in 2015, an official from Terrapower, the nuclear venture funded in part by Bill Gates, noted that his company was “excited to celebrate and build upon” the experiment by designing a molten chloride fast reactor. His accompanying slide show reinforced the message with pictures of the Molten Salt Reactor Experiment assembly, the red hot heat exchanger, and Alvin Weinberg, the leader of Oak Ridge at that time, noting that the experiment had operated for 6,000 hours. Also in 2015, Terrestrial Energy’s David LeBlanc made “a kind of pilgrimage to Oak Ridge” to celebrate the 50th anniversary of the Molten Salt Reactor Experiment becoming critical.

Many molten salt reactor developers and proponents seem to have decided that the Molten Salt Reactor Experiment experience was so successful that all that remains is for it to be scaled up and deployed across the world. But is this really the case? A careful look suggests otherwise.

Molten salt reactors’ early history. Molten salt reactors go back to the US Air Force’s failed effort to build a nuclear-powered, long-range bomber aircraft. The Air Force spent more than $1 billion (over $7 billion in today’s dollars) between 1946 and 1961 on its Aircraft Nuclear Propulsion program. President John F. Kennedy, seeing how little had been achieved, told Congress on March 28, 1961 that the possibility of success in the foreseeable future was “still very remote” and recommended terminating the program.

As part of this effort, the Air Force made Oak Ridge National Laboratory responsible for building the Aircraft Reactor Experiment as part of its effort to fly a bomber on nuclear power. The 2.5 megawatt reactor operated for a mere nine days in November 1954. Some Oak Ridge officials considered running the reactor longer, but others grew concerned about overheating of one of the reactor components. That concern was legitimate; five days later, this component failed and “released radioactive gas into the reactor compartment.” But Oak Ridge National Lab officials were undeterred. For them, the experience showed “the feasibility of molten-salt fuel” and they “persuaded the Atomic Energy Commission to fund a study of molten-salt power reactors.” In 1958, the commission did just that, and thus began the Molten Salt Reactor Experiment.

To understand the interest in molten salt reactors, start by adopting a 1950s mindset. At the time, nuclear power was expected to expand rapidly, and some energy planners were worried that there would be insufficient uranium to fuel all the reactors to be built over upcoming decades. Alvin Weinberg, the head of Oak Ridge, expressed this eloquently when he prophesized that humanity would need to “burn the rocks” in what are called breeder reactors in order to live a “passably abundant life.” While the dominant types of reactors around the world (light water reactors and heavy water reactors) use only a small fraction of the uranium and thorium found in the Earth’s crust, breeder reactors can exploit a much larger fraction of these minerals.

The concern among nuclear power advocates about running out of uranium was also at the heart of another major nuclear development during this period: the liquid metal (sodium) cooled fast breeder reactor. These reactors were an effort to tap the energy present in the uranium-238 isotope that is not used in standard light and heavy water reactors by converting it into plutonium. Glenn Seaborg, who discovered the element and rose to become Chairman of the US Atomic Energy Commission from 1961 to 1971, predicted in 1970 that, by the year 2000, plutonium “can be expected to be a predominant energy source in our lives.” By contrast, the molten salt reactors were mostly intended as a pathway to use thorium, which was more plentiful than uranium, by converting it into uranium-233.

In retrospect, these expectations proved mistaken in three ways. First, energy demand has risen much more slowly, both in the United States and globally, than predicted. For example, in 1959, Weinberg assumed that the global population would stabilize at 7 billion and that it would need at least 1.9 billion, billion BTU per year. In comparison, in 2020, the world used a little over a quarter of this level of energy for nearly 8 billion people.

Second, nuclear energy proved much more expensive than envisioned in the heady “too cheap to meter” era. As nuclear power’s poor economics became apparent, reactor construction declined dramatically and has never achieved anywhere near the levels seen in the 1970s and 1980s. (Accidents at Three Mile Island and Chernobyl only reinforced this trend.) The United States illustrates the drastic difference between expectation and reality. The Atomic Energy Commission projected that US nuclear power generating capacity in 2000 would be 1.1 million megawatts (or 1,100 gigawatts). In fact, US nuclear capacity only reached a maximum of 101 gigawatts, and it has since declined to less than 95 gigawatts as of June 2022 (after the Palisades reactor was shut down). Globally, nuclear energy’s share of electricity generation has sunk from a maximum of 17.5 percent in 1996 to just over 10 percent in 2020.

Third, uranium proved to be more ubiquitous than anticipated, and global uranium resource estimates have continuously increased. The International Atomic Energy Agency and the Organization for Economic Co-operation and Development’s Nuclear Energy Agency calculate that the world’s resources of cheaply available uranium ore are adequate to fuel the global reactor fleet, even in the event of an increase in nuclear power generation.

All of these realizations were, of course, only to be had in the future. In the 1950s, when the molten salt reactor programs were actively pursued, there was an air of urgency. This urgency was reflected in the break-neck speed with which the Molten Salt Reactor Experiment, Oak Ridge’s proposal for the next step in the molten salt reactor research process, was designed and constructed. As one of the Oak Ridge team leaders described it, “Design of the [Molten Salt Reactor Experiment] started in the summer of 1960, and construction started 18 months later, at the beginning of 1962. The reactor went critical in June 1965.”

In 1965, when the reactor started operating, it was fueled by a mixture of 150 kilograms of depleted uranium and 90 kilograms of weapons-grade, highly-enriched uranium (93 percent of uranium-235). After March 1968, the fuel was changed to one involving another weapons-usable material, uranium-233, which was derived from thorium. After this switch, the Molten Salt Reactor Experiment went critical in October 1968 and reached full power in January 1969. But at the end of that year, the experiment shut down. No more molten salt reactors have been built since.

The Molten Salt Reactor Experiment operation. Proponents of molten salt reactors have claimed for decades that the Molten Salt Reactor Experiment operated successfully. Indeed, they started making this claim even when it had barely started operating. In May 1966, for example, Paul Haubenreich, Oak Ridge National Laboratory associate director, cockily announced that the experiment “will live up to the name which we think goes with the initials M.S.R.E.—Mighty Smooth Running Experiment.” This, after listing many problems, including a basic one that was never resolved.

Molten Salt Reactor Experiment remote handling cell.

By Oak Ridge National Laboratory. Accessed via Flickr. CC BY 2.0.

That basic problem was the reactor’s power level. The Molten Salt Reactor Experiment was designed to produce 10 megawatts (MW) of heat. The power level is given only in terms of heat production because its designers did not even try to generate electricity from the power produced in the reactor. Instead, the experiment just dissipated the heat produced to the surrounding air.

But this design power level was never reached. As Haubenreich described while pronouncing that the experiment was running “mighty smooth,” the operators “ran into some difficulties” and could only operate “at powers up to 5 MW.” Nevertheless, he expressed the confident expectation that the reactor would “be at 10 MW within a couple of weeks.” In fact, Haubenreich later admitted in a paper written after the reactor was shut down, the highest power level it reached was only 8 MW. (One Oak Ridge publication even says 7.4 MW.) It turned out that the designers of the reactor had “miscalculated the heat transfer characteristics” of the system used for dissipating the heat produced into the atmosphere, and the reactor could not operate at its intended power level.

Even for this lower power output, operations were anything but smooth. At the most general level, the fact that the reactor operated for just 13,172 hours over those four years, or only around 40 percent of the time. In comparison, the average commercial nuclear power plant in the United States operates at upwards of 90 percent of the time. The longest periods of sustained high power operations in the Molten Salt Reactor Experiment were between February to May in 1967 and late January to May in 1969.

During its operational lifetime, the Molten Salt Reactor Experiment was shut down 225 times. Of these 225 interruptions, only 58 were planned. The remaining interruptions were due to various technical problems, including: “chronic plugging” of the pipes that led into charcoal beds intended to capture and remove radioactive materials so the reactor could operate; failures of the blowers that removed the heat produced in the reactor; and fuel draining through the so-called freeze valve safety system intended to prevent an accident.

These frequent failures led to a large gap between the proposed operating schedule and the actual operations of the Molten Salt Reactor Experiment. For example, the proposed schedule called for the experiment to run at full power (i.e. 8 MW) from May to early August in 1968. But the reactor was down from April to July of that year.

One persistent problem was with the electrical system, which experienced “eleven important failures.” Of these, five were “caused by electrical storms, one by a cable failure at a component-cooling pump, one by an overload of the main process-power breaker, one by an arc between a 13.8-kV line and an activator rod to the line fuse, one by a failure of the main transformer primary fuse, one by a failure of the auxiliary transformer primary fuse, and one by a failure of the drain-tank space cooler motor. These interruptions varied in length from a few minutes to several days.” Such unexpected failures and shutdowns ended only in December 1969, when the Molten Salt Reactor Experiment was shut down.

The patchy experience of the experiment was by no means unique. Many other reactor designs have been plagued by unreliable operations and frequent shutdowns, that in many cases only became worse when scaled up. Consider, for example, sodium cooled fast breeder reactors. France, the country most reliant on nuclear power, tried to commercialize this technology after operating pilot-scale and demonstration reactors. This “commercial” version was the Superphénix, which started operating in 1986, experienced a series of accidents, and was shut down in 1997. During this period, it generated less than 8 percent of the electrical energy of what it would have generated running at full power round-the-clock. In the United States, the first and only commercial sodium cooled breeder reactor, Fermi-1, suffered a disastrous meltdown in 1966 as a result of a series of failures that had been dismissed as not credible by reactor engineers. Likewise, high-temperature, gas-cooled reactors have historically performed poorly.

The Molten Salt Reactor Experiment aftermath. For Oak Ridge officials and other molten salt reactor proponents, these problems with the Molten Salt Reactor Experiment were not worthy of significant concern. They moved forward with plans to build a larger molten salt breeder reactor. (Remember that the ultimate goal was to use thorium to breed nuclear fuel.) But the experiment did identify major hurdles in the path of building reliable molten salt reactors.

Here’s a key concern: Materials used to manufacture molten-salt-reactor components must maintain their integrity in highly radioactive and corrosive environments at elevated temperatures. The corrosion is a result of the reactor’s nature, which involves the use of a fuel consisting of uranium mixed with the hot salts for which the reactor is named. As anyone living near a seashore knows, chemically corrosive salt water eats most metallic objects.

To deal with this problem, Oak Ridge developed a new alloy known as IN0R-8 or Hastelloy-N in the late 1950s. While Hastelloy-N did not get significantly corroded—at least during the four years of intermittent operations—it had two significant problems. First, the material had trouble managing stresses. It became brittle, for example. Second the material developed cracks on surfaces exposed to the fuel salt. Both of these could lead to the component failing.

These problems remain relevant. Even today, no material can perform satisfactorily in the high-radiation, high-temperature, and corrosive environment inside a molten salt reactor. In 2018, scientists at the Idaho National Laboratory conducted an extensive review of different materials and, in the end, could only recommend that “a systematic development program be initiated.” In other words, fifty years after the molten salt reactor was shut down, technical experts still have questions about materials development for a new molten salt reactor design.

A few years after the Molten Salt Reactor Experiment was shut down, the Atomic Energy Commission terminated the entire molten salt reactor program, although it continued to fund the molten salt breeder reactor program until the end of fiscal year 1976.

Molten salt reactor proponents view the termination of funding as a result of either institutional politics or historical factors. They point to Milton Shaw—the head of the Atomic Energy Commission’s Division of Reactor Development and Technology—and his strong preference for the liquid metal fast breeder reactor. As Oak Ridge National Laboratory program director Herbert MacPherson put it, the “fast breeder program… got an early start and had copious government development funds being spent in many parts of the United States. When the [molten salt reactor] development program had progressed far enough to justify a greatly expanded program leading to commercial development, the [Atomic Energy Comission] could not justify the diversion of substantial funds” from these efforts. MacPherson suggested that the institutional problem was that the “political and technical support” for molten salt reactors was “too thin geographically.”

Director Alvin Weinberg’s explanation revolved around the historical domination of nuclear power by physicists. In a letter to Glenn Seaborg, he wrote, “our problem is not that our idea is a poor one—rather it is different from the main line, and has too chemical a flavor to be fully appreciated by non-chemists.”

But these explanations disregard the technological problems of molten salt reactors. Indeed, anyone who looked at the spotty operating record of the Oak Ridge reactor ought to have been skeptical about this technology. The subsequent failure of the seemingly more promising fast breeder reactor technology should prompt greater skepticism, not less.

The Atomic Energy Commission, for its part, justified its decision in a devastating report that listed a number of problems with the large molten salt reactor that Oak Ridge scientists had conceptualized. The list included problems with materials, some of which have been earlier described; the challenge of controlling the radioactive tritium gas that is produced in molten salt reactors; the many large components, such as steam generators, that woud have to be developed from scratch (as researchers had no experience with such components for a molten salt reactor); the difficulties associated with molten-salt-reactor maintenance because radioactive fission products would be dispersed throughout the reactor; some safety disadvantages (though these are balanced by pointing out some of the safety advantages); and problems with graphite, which is used in molten-salt-reactor designs to slow down neutrons, because it swells when subjected to the nuclear reactor’s high radiation doses.

Other institutions too questioned the idea. A 1975 Office of Technology Assessment report listed the pros and cons of maintaining support for the molten salt breeder reactor program. An important set of arguments listed there proved prescient: “the [molten salt breeder reactor] may never work, its economics would be doubtful even if it did, and the chances of needing it are small.” As a result, in the years after the Molten Salt Reactor Experiment was shut down, many arguments were advanced to abandon the molten salt route, including not throwing good money after bad.

The Molten Salt Reactor Experiment’s long difficult tail. When one looks for publications with the title “molten salt reactor experiment” on the University of British Columbia library page, only nine results, all published before 1975, pertain to the actual operations of the reactor. The remaining 41, including a 1984 report titled “Preliminary decommissioning study reports: Volume 5, Molten Salt Reactor Experiment,” all deal with managing the reactor components or the radioactive materials involved in the experiment. The distribution of the numbers of papers indicates the challenge of dealing with the waste resulting from a small molten salt reactor.

Dealing with radioactive salt wastes involves at least two separate concerns. The first, ongoing problem is that managing the radioactive salts that contain the uranium isotopes and the fission products is difficult. In the 1990s, researchers discovered that uranium had migrated and settled in other parts of the facility, leading to the possibility of an accidental criticality.

The second challenge is that of securely storing the uranium-233 from the Molten Salt Reactor Experiment. Although the uranium-233 used in the Molten Salt Reactor Experiment is but a small part of the larger US stockpile of the substance, it occurs in chemical forms that are difficult to manage. Further, urarnium-233 is usable in nuclear weapons, and any loss of this material might lead to security concerns.

In all, the costs incurred so far have run into the hundreds of millions of dollars—dozens of times the cost of constructing the reactor itself. Oak Ridge continues to spend around ten million dollars (roughly the cost of the reactor) every year, just to manage these wastes on site. In addition to the problems mentioned above, there are miscellaneous challenges requiring expensive engineering. For example, Oak Ridge began a $4.7 million project in 2019 to upgrade electrical and fire suppression systems.

Assuming that these challenges can all be managed, Oak Ridge and the Department of Energy will also need to address the ultimate challenge of trying to dispose of these wastes in some kind of a geological repository. Uranium in molten salt reactors is in chemical forms that are “not known to occur in nature” and waste disposal experts are unclear “which, if any, disposal environment could accommodate this high-level waste.”

Molten salt reactors are a bad idea. The Molten Salt Reactor Experiment’s history is riddled with extensive problems, both during its operational lifetime and the half century thereafter. These problems were not accidental but a result of the many material challenges faced by the reactor itself.

Any other molten salt reactor will encounter these problems too. France’s Institut de Radioprotection et de Sûreté Nucléaire, the Nuclear Innovation and Research Office in the United Kingdom, and other research laboratories have all drawn this conclusion. According to the Institut de Radioprotection et de Sûreté Nucléaire, “numerous technological challenges remain to be overcome before the construction of an MSR can be considered.”

Should molten salt reactors ever be constructed, they are unlikely to operate reliably. And if they are deployed, they would likely result in various safety and security risks. And they would produce several different waste streams, all of which would require extensive processing and would face disposal related challenges. Investing in molten salt reactors is not worth the cost or the effort.

This article has benefited from research support from Maggie Chong, a materials engineering student at the University of British Columbia.

That basic problem was the reactor’s power level. The Molten Salt Reactor Experiment was designed to produce 10 megawatts (MW) of heat. The power level is given only in terms of heat production because its designers did not even try to generate electricity from the power produced in the reactor. Instead, the experiment just dissipated the heat produced to the surrounding air.

But this design power level was never reached. As Haubenreich described while pronouncing that the experiment was running “mighty smooth,” the operators “ran into some difficulties” and could only operate “at powers up to 5 MW.” Nevertheless, he expressed the confident expectation that the reactor would “be at 10 MW within a couple of weeks.” In fact, Haubenreich later admitted in a paper written after the reactor was shut down, the highest power level it reached was only 8 MW. (One Oak Ridge publication even says 7.4 MW.) It turned out that the designers of the reactor had “miscalculated the heat transfer characteristics” of the system used for dissipating the heat produced into the atmosphere, and the reactor could not operate at its intended power level.

Even for this lower power output, operations were anything but smooth. At the most general level, the fact that the reactor operated for just 13,172 hours over those four years, or only around 40 percent of the time. In comparison, the average commercial nuclear power plant in the United States operates at upwards of 90 percent of the time. The longest periods of sustained high power operations in the Molten Salt Reactor Experiment were between February to May in 1967 and late January to May in 1969.

During its operational lifetime, the Molten Salt Reactor Experiment was shut down 225 times. Of these 225 interruptions, only 58 were planned. The remaining interruptions were due to various technical problems, including: “chronic plugging” of the pipes that led into charcoal beds intended to capture and remove radioactive materials so the reactor could operate; failures of the blowers that removed the heat produced in the reactor; and fuel draining through the so-called freeze valve safety system intended to prevent an accident.

These frequent failures led to a large gap between the proposed operating schedule and the actual operations of the Molten Salt Reactor Experiment. For example, the proposed schedule called for the experiment to run at full power (i.e. 8 MW) from May to early August in 1968. But the reactor was down from April to July of that year.

One persistent problem was with the electrical system, which experienced “eleven important failures.” Of these, five were “caused by electrical storms, one by a cable failure at a component-cooling pump, one by an overload of the main process-power breaker, one by an arc between a 13.8-kV line and an activator rod to the line fuse, one by a failure of the main transformer primary fuse, one by a failure of the auxiliary transformer primary fuse, and one by a failure of the drain-tank space cooler motor. These interruptions varied in length from a few minutes to several days.” Such unexpected failures and shutdowns ended only in December 1969, when the Molten Salt Reactor Experiment was shut down.

The patchy experience of the experiment was by no means unique. Many other reactor designs have been plagued by unreliable operations and frequent shutdowns, that in many cases only became worse when scaled up. Consider, for example, sodium cooled fast breeder reactors. France, the country most reliant on nuclear power, tried to commercialize this technology after operating pilot-scale and demonstration reactors. This “commercial” version was the Superphénix, which started operating in 1986, experienced a series of accidents, and was shut down in 1997. During this period, it generated less than 8 percent of the electrical energy of what it would have generated running at full power round-the-clock. In the United States, the first and only commercial sodium cooled breeder reactor, Fermi-1, suffered a disastrous meltdown in 1966 as a result of a series of failures that had been dismissed as not credible by reactor engineers. Likewise, high-temperature, gas-cooled reactors have historically performed poorly.

The Molten Salt Reactor Experiment aftermath. For Oak Ridge officials and other molten salt reactor proponents, these problems with the Molten Salt Reactor Experiment were not worthy of significant concern. They moved forward with plans to build a larger molten salt breeder reactor. (Remember that the ultimate goal was to use thorium to breed nuclear fuel.) But the experiment did identify major hurdles in the path of building reliable molten salt reactors.

Here’s a key concern: Materials used to manufacture molten-salt-reactor components must maintain their integrity in highly radioactive and corrosive environments at elevated temperatures. The corrosion is a result of the reactor’s nature, which involves the use of a fuel consisting of uranium mixed with the hot salts for which the reactor is named. As anyone living near a seashore knows, chemically corrosive salt water eats most metallic objects.

To deal with this problem, Oak Ridge developed a new alloy known as IN0R-8 or Hastelloy-N in the late 1950s. While Hastelloy-N did not get significantly corroded—at least during the four years of intermittent operations—it had two significant problems. First, the material had trouble managing stresses. It became brittle, for example. Second the material developed cracks on surfaces exposed to the fuel salt. Both of these could lead to the component failing.

These problems remain relevant. Even today, no material can perform satisfactorily in the high-radiation, high-temperature, and corrosive environment inside a molten salt reactor. In 2018, scientists at the Idaho National Laboratory conducted an extensive review of different materials and, in the end, could only recommend that “a systematic development program be initiated.” In other words, fifty years after the molten salt reactor was shut down, technical experts still have questions about materials development for a new molten salt reactor design.

A few years after the Molten Salt Reactor Experiment was shut down, the Atomic Energy Commission terminated the entire molten salt reactor program, although it continued to fund the molten salt breeder reactor program until the end of fiscal year 1976.

Molten salt reactor proponents view the termination of funding as a result of either institutional politics or historical factors. They point to Milton Shaw—the head of the Atomic Energy Commission’s Division of Reactor Development and Technology—and his strong preference for the liquid metal fast breeder reactor. As Oak Ridge National Laboratory program director Herbert MacPherson put it, the “fast breeder program… got an early start and had copious government development funds being spent in many parts of the United States. When the [molten salt reactor] development program had progressed far enough to justify a greatly expanded program leading to commercial development, the [Atomic Energy Comission] could not justify the diversion of substantial funds” from these efforts. MacPherson suggested that the institutional problem was that the “political and technical support” for molten salt reactors was “too thin geographically.”

Director Alvin Weinberg’s explanation revolved around the historical domination of nuclear power by physicists. In a letter to Glenn Seaborg, he wrote, “our problem is not that our idea is a poor one—rather it is different from the main line, and has too chemical a flavor to be fully appreciated by non-chemists.”

But these explanations disregard the technological problems of molten salt reactors. Indeed, anyone who looked at the spotty operating record of the Oak Ridge reactor ought to have been skeptical about this technology. The subsequent failure of the seemingly more promising fast breeder reactor technology should prompt greater skepticism, not less.

The Atomic Energy Commission, for its part, justified its decision in a devastating report that listed a number of problems with the large molten salt reactor that Oak Ridge scientists had conceptualized. The list included problems with materials, some of which have been earlier described; the challenge of controlling the radioactive tritium gas that is produced in molten salt reactors; the many large components, such as steam generators, that woud have to be developed from scratch (as researchers had no experience with such components for a molten salt reactor); the difficulties associated with molten-salt-reactor maintenance because radioactive fission products would be dispersed throughout the reactor; some safety disadvantages (though these are balanced by pointing out some of the safety advantages); and problems with graphite, which is used in molten-salt-reactor designs to slow down neutrons, because it swells when subjected to the nuclear reactor’s high radiation doses.

Other institutions too questioned the idea. A 1975 Office of Technology Assessment report listed the pros and cons of maintaining support for the molten salt breeder reactor program. An important set of arguments listed there proved prescient: “the [molten salt breeder reactor] may never work, its economics would be doubtful even if it did, and the chances of needing it are small.” As a result, in the years after the Molten Salt Reactor Experiment was shut down, many arguments were advanced to abandon the molten salt route, including not throwing good money after bad.

The Molten Salt Reactor Experiment’s long difficult tail. When one looks for publications with the title “molten salt reactor experiment” on the University of British Columbia library page, only nine results, all published before 1975, pertain to the actual operations of the reactor. The remaining 41, including a 1984 report titled “Preliminary decommissioning study reports: Volume 5, Molten Salt Reactor Experiment,” all deal with managing the reactor components or the radioactive materials involved in the experiment. The distribution of the numbers of papers indicates the challenge of dealing with the waste resulting from a small molten salt reactor.

Dealing with radioactive salt wastes involves at least two separate concerns. The first, ongoing problem is that managing the radioactive salts that contain the uranium isotopes and the fission products is difficult. In the 1990s, researchers discovered that uranium had migrated and settled in other parts of the facility, leading to the possibility of an accidental criticality.

The second challenge is that of securely storing the uranium-233 from the Molten Salt Reactor Experiment. Although the uranium-233 used in the Molten Salt Reactor Experiment is but a small part of the larger US stockpile of the substance, it occurs in chemical forms that are difficult to manage. Further, urarnium-233 is usable in nuclear weapons, and any loss of this material might lead to security concerns.

In all, the costs incurred so far have run into the hundreds of millions of dollars—dozens of times the cost of constructing the reactor itself. Oak Ridge continues to spend around ten million dollars (roughly the cost of the reactor) every year, just to manage these wastes on site. In addition to the problems mentioned above, there are miscellaneous challenges requiring expensive engineering. For example, Oak Ridge began a $4.7 million project in 2019 to upgrade electrical and fire suppression systems.

Assuming that these challenges can all be managed, Oak Ridge and the Department of Energy will also need to address the ultimate challenge of trying to dispose of these wastes in some kind of a geological repository. Uranium in molten salt reactors is in chemical forms that are “not known to occur in nature” and waste disposal experts are unclear “which, if any, disposal environment could accommodate this high-level waste.”

Molten salt reactors are a bad idea. The Molten Salt Reactor Experiment’s history is riddled with extensive problems, both during its operational lifetime and the half century thereafter. These problems were not accidental but a result of the many material challenges faced by the reactor itself.

Any other molten salt reactor will encounter these problems too. France’s Institut de Radioprotection et de Sûreté Nucléaire, the Nuclear Innovation and Research Office in the United Kingdom, and other research laboratories have all drawn this conclusion. According to the Institut de Radioprotection et de Sûreté Nucléaire, “numerous technological challenges remain to be overcome before the construction of an MSR can be considered.”

Should molten salt reactors ever be constructed, they are unlikely to operate reliably. And if they are deployed, they would likely result in various safety and security risks. And they would produce several different waste streams, all of which would require extensive processing and would face disposal related challenges. Investing in molten salt reactors is not worth the cost or the effort.

This article has benefited from research support from Maggie Chong, a materials engineering student at the University of British Columbia.

No comments:

Post a Comment