Jacobs to design remotely-operated tools for ITER

26 April 2023

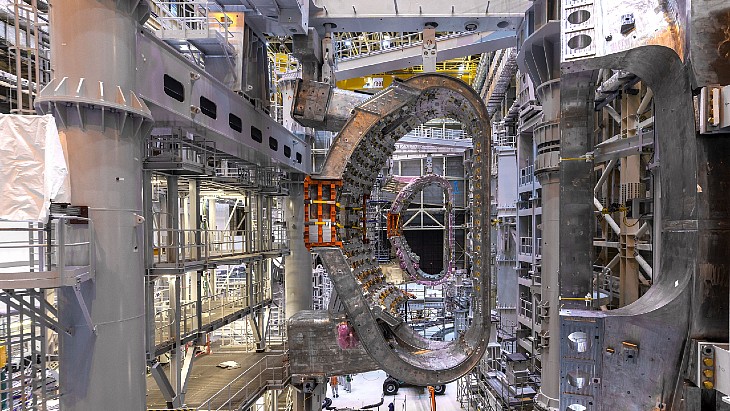

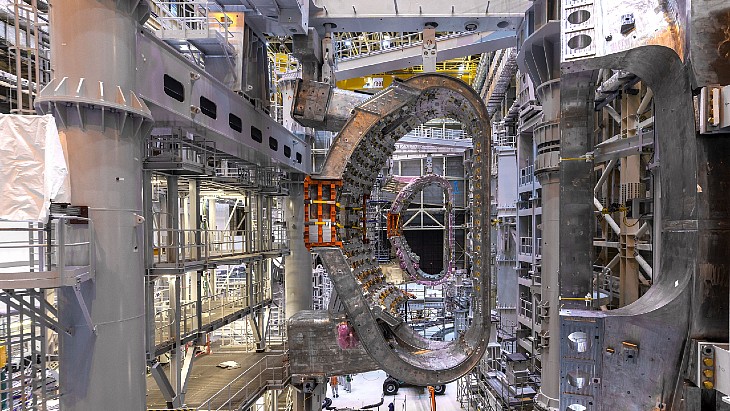

Jacobs has been awarded a contract to design and engineer maintenance systems for the International Thermonuclear Experimental Reactor (ITER) fusion project.

(Image: ITER)

(Image: ITER)The contract covers work on up to 25 diagnostic ports and systems in the multinational ITER fusion reactor being built in southern France. It is for four years with a possible two-year extension, Jacobs said, with the company designing and engineering remotely-operated tools.

Karen Wiemelt, Jacobs Energy, Security and Technology senior vice president, said: "Our support of the maintenance of these diagnostics systems not only delivers on Jacobs' commitment to climate response but also our purpose of creating a more connected, sustainable world ... through our team in Aix-en-Provence, combined with the full strength of Jacobs' global capability, we will work with ITER to channel our technology-enabled knowledge and experience toward benefiting people and the planet."

ITER is a major international project to build a tokamak fusion device in Cadarache, France, designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy. The goal of ITER is to operate at 500 MW (for at least 400 seconds continuously) with 50 MW of plasma heating power input. It appears that an additional 300 MWe of electricity input may be required in operation. No electricity will be generated at ITER.

Thirty-five nations are collaborating to build ITER - the European Union is contributing almost half of the cost of its construction, while the other six members (China, India, Japan, South Korea, Russia and the USA) are contributing equally to the rest. Construction began in 2010 and the original 2018 first plasma target date was put back to 2025 by the ITER council in 2016. That timeline for first plasma is currently in the process of being revised, following the COVID-19 pandemic and the discovery of defects in the thermal shields and vacuum vessel sector.

Researched and written by World Nuclear News

Chinese and German milestones in fusion research

13 April 2023

A Chinese tokamak device has set a new world record for a steady-state high-constraint mode plasma operation and German researchers have discovered a way to build smaller and cheaper fusion reactors. Meanwhile a US Government Accountability Office report on achieving commercial fusion cautions that several challenges must still be overcome.

.jpg?ext=.jpg) The EAST tokamak (Image: Hefei Institutes of Physical Science)

The EAST tokamak (Image: Hefei Institutes of Physical Science)On 12 April, China's experimental advanced superconducting tokamak (EAST), known as the 'artificial sun', set a new world record and successfully achieved a steady-state high-constraint mode plasma operation for 403 seconds. The previous record was 101 seconds, set by EAST in 2017.

The breakthrough was achieved after more than 120,000 shots in EAST, located at the Institute of Plasma Physics under the Chinese Academy of Sciences (ASIPP) in Hefei, Anhui Province.

The temperature and density of particles have been greatly increased during high confinement plasma operation, which will lay a solid foundation for improving the power generation efficiency of future fusion power plants and reducing costs, ASIPP Director Song Yuntao told the Xinhua news agency.

Since starting operation in 2006, EAST has been an open test platform for Chinese and international scientists to conduct fusion-related experiments and research. Currently, the engineering design of the future China Fusion Engineering Test Reactor (CFETR) - which is seen as the next-generation 'artificial sun' - has been completed, aiming at being the world's first fusion demonstration reactor.

Smaller and cheaper devices

Meanwhile, researchers at Germany's Max Planck Institute for Plasma Physics (IPP) have found a way to significantly reduce the distance needed between the hot plasmas in nuclear fusion devices and the vessel wall.

The ASDEX Upgrade tokamak experiment at IPP in Garching near Munich serves as a blueprint for International Thermonuclear Experimental Reactor (ITER) and later fusion power plants. Important elements for ITER were developed there. Plasma operating conditions and components for later power plants are already being tested.

A central element of ASDEX Upgrade and all modern magnetic fusion facilities is the divertor. This is a part of the vessel wall that is particularly heat-resistant and requires an elaborate design. In order to handle the high temperatures, the divertor tiles of ASDEX Upgrade and also of ITER are made of tungsten, the chemical element with the highest melting temperature (3422°C).

Without countermeasures, 20% of the fusion power of the plasma would reach the divertor surfaces. For this reason, small amounts of impurities (often nitrogen) are added to the plasma. These extract most of its thermal energy by converting it into ultraviolet light. Nevertheless, the plasma edge (the separatrix) must be kept at a distance from the divertor to protect it. In ASDEX Upgrade until now, this has been at least 25 centimetres (measured from the lower plasma tip - the X-point - to the edges of the divertor).

Researchers at IPP have now succeeded in reducing this distance to less than 5 centimetres without damaging the wall.

"We accidentally moved the plasma edge much closer to the divertor than we had intended," IPP physicist Tilmann Lunt said. "We were very surprised that ASDEX Upgrade coped with this without any problems."

"Because the plasma moves closer to the divertor, the vacuum vessel volume can be better utilised," IPP said. "Initial calculations show that if the vessel were optimally shaped, it would be possible to almost double the plasma volume while maintaining the same dimensions. This would also increase the achievable fusion power."

"We are dealing with a significant discovery in fusion research," said IPP Division Director Ulrich Stroth. "The X-point radiator opens up completely new possibilities for us in the development of a power plant. We will further investigate the theory behind it and try to understand it better by new experiments at ASDEX Upgrade."

Challenges still remain

The two announcements came as the US Government Accountability Office (GAO) released a report concluding fusion technology faces many challenges before it can produce commercial electricity.

"Several challenges must be overcome to achieve commercial fusion, and stakeholders' projections of this timeline range from 10 years to several decades," GAO said. "One key scientific challenge is in the physics of plasmas, the state of matter needed for fusion."

Researchers have made advancements in understanding the behaviour of burning plasmas but lack sufficient experimental data to validate their simulations, the report says. One key engineering challenge is the development of materials that can withstand fusion conditions for decades, such as extreme heat and neutron damage, and no facility exists where materials can be fully tested. "More generally, the task of extracting energy from fusion to provide an economical source of electric power presents several complex systems engineering problems that have yet to be solved."

The report noted that public and private sector misalignments, regulatory uncertainty, and other factors also present challenges to fusion energy development. One area of misalignment is research priorities. Public sector efforts prioritise basic science, but fusion energy development requires an additional emphasis on technology and engineering research. Another factor is regulatory uncertainty, which could slow development of fusion energy, although developing appropriate regulations to ensure safety without constraining development is difficult.

GAO developed four policy options that could help address these challenges or enhance the benefits of fusion energy. They identify possible actions by policymakers, which include legislative bodies, government agencies, academia, industry and other groups.

Researched and written by World Nuclear News

.jpg?ext=.jpg) The new hot cells in use at BNL's MIRP (Image: BNL)

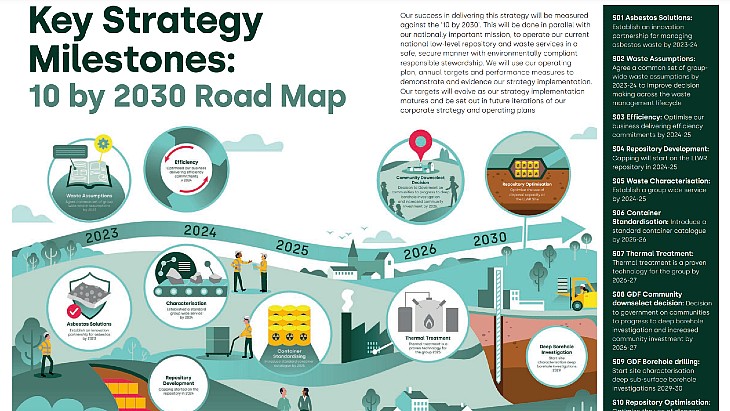

The new hot cells in use at BNL's MIRP (Image: BNL) The strategy is focused on goals to hit by 2030 (Image: NWS corporate strategy report 2023)

The strategy is focused on goals to hit by 2030 (Image: NWS corporate strategy report 2023).jpg?ext=.jpg) (Image: NuScale)

(Image: NuScale).jpg)

_1.jpg?ext=.jpg) Takahama (Image: Kansai)

Takahama (Image: Kansai).jpg?ext=.jpg) (Image: Framatome)

(Image: Framatome).jpg?ext=.jpg) Winter exploration work at PLS (Image: Fission Uranium)

Winter exploration work at PLS (Image: Fission Uranium).jpg?ext=.jpg) The existing Borssele plant (Image: ANVS)

The existing Borssele plant (Image: ANVS) (Image: ITER)

(Image: ITER).jpg?ext=.jpg) The EAST tokamak (Image: Hefei Institutes of Physical Science)

The EAST tokamak (Image: Hefei Institutes of Physical Science).jpg?ext=.jpg) The Rescue Robot (Image: Forth)

The Rescue Robot (Image: Forth)