With the historic climate agreement adopted by the IMO just before Easter, shipping has become the first industry to face a globally established price on greenhouse gas emissions. The new regulations place limits on emissions and require companies to pay for any emissions exceeding a certain threshold. Additional costs will apply for failing to meet minimum reduction targets, while vessels using net-zero fuels or technologies will be financially rewarded. This is expected to inspire further action to cut emissions and will, naturally, be a central topic across several Nor-Shipping stages.

Discussions will focus on the availability and range of green fuels, fuel-agnostic vessels, and the broader infrastructure required to support the energy transition. The engines and technologies are already in place, and ships are being built to run on fuels like ammonia and methanol. However, fuel supply and port infrastructure remain major bottlenecks that must be addressed.

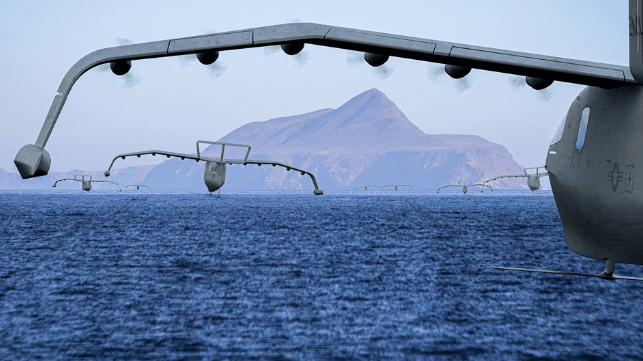

Although green fuels are the long-term goal, immediate action to reduce emissions from the existing fleet is equally critical. Wind-assisted propulsion, onboard carbon capture systems, air lubrication on hulls, waste heat recovery, battery hybridization, increased use of shore power, digitalization, speed and route optimization, just-in-time arrivals, and other measures can all deliver significant results today.

Conferences program you don’t want to miss!

This year's program kicks off, in good tradition, with the flagship Ocean Leadership Conference, and continues with focused sessions on Offshore Wind, Ship Autonomy & AI, Maritime Hydrogen, and Offshore Aquaculture. New to this year’s event are the first-ever Nor-Shipping LNG Conference, Deepsea Minerals Conference, and Ocean Invest Conference, all taking place within the main conference arena at Lillestrøm.

In addition, we will have our popular Blue Talks, offering one-hour sessions and panel discussions on key topics related to sustainable business development across the ocean space. This year, the Blue Talks stage will host more than 14 topical keynotes and debates from Tuesday through Thursday. There is truly something for everyone in the 2025 program.

Strong heritage builds global partnerships

Norway has long been a global frontrunner in shipbuilding, digitalization, decarbonization, and autonomous shipping, thanks to its long-standing maritime heritage. This rich history has helped pave the way for the creation and evolution of Nor-Shipping.

One of Norway’s greatest strengths is its aim to have a collaborative maritime ecosystem with strong ties between government, academia, technology providers, and shipowners, in order to create fertile ground for innovation and sustainability. This cross-sector approach, combined with a future-focused regulatory mindset, has helped Norway stay at the forefront of maritime transformation and innovation.

International collaboration is, however, key to future global success. Nor-Shipping is committed to supporting this vision by providing an international arena that builds bridges and encourages cooperation, innovation, and knowledge-sharing. By hosting events like this, we can enable countries to not only shares its experience, but also learn from each other and build partnerships.

To further strengthen our international platform, Nor-Shipping will continue to host country-specific seminars on strategic markets, such as Singapore, Brazil, India and China, to further build on our commitment to being a leading global meeting place for the maritime industry.

Empowering the Next Generation

Nor-Shipping aims to become a key meeting place for the maritime industry and students seeking career opportunities. With a focus on learning, networking, and inspiration, a series of new and expanded initiatives aim to connect young talent with the industry.

“One of the most important investments we can make in creating a future-proof industry is recruiting the right talent, fostering innovation, and inspiring young people to explore career paths within the field,” says Sidsel Norvik, Director of Nor-Shipping.

An important part of this commitment is Nor-Shipping’s newly established Ambassador Programme. In partnership with Njord Maritime Studentforening, the initiative is being actively promoted to students across the Greater Oslo Region. Njord has recruited a passionate group of maritime students from various universities to raise awareness among their peers. These ambassadors play a key role in highlighting the many opportunities Nor-Shipping offers, including career exploration, networking, educational sessions, and industry insights.

Ocean Campus, led by the World Maritime University and other leading institutions, will have its own dedicated floor this year, featuring daily talks and offering insights into educational opportunities for maritime students. New to the programme is Career Port, a dedicated platform where companies will present career opportunities directly to students and young professionals, followed by informal mingling and networking sessions.

Innovation is crucial to the maritime industry, and the Startup Area offers a front-row seat to the ideas and technologies shaping the future of ocean industries. Providing a global stage for emerging talent and new ideas is essential to ensuring long-term industry success. This makes the area incredibly interesting, inspirational, and relevant, not just for professionals and investors, but also for students and other attendees.

Together, these initiatives position Nor-Shipping as an important arena for shaping the next generation of maritime talent and driving the industry forward.

The perfect balance of exhibition, insight and networking

Nor-Shipping is built on three key pillars:

1) An outstanding exhibition, showcasing the latest innovations, technologies, designs, and developments from across the global maritime industry;

2) an industry-leading conference program, covering a broad range of vital segments within maritime; and

3) a second-to-none networking program, featuring BBQs, daily AfterWork gatherings, and an unforgettable Anniversary Party on Thursday night.

Together, these pillars create a dynamic five-day, around-the-clock experience that sets Nor-Shipping apart on the global stage.

This content is sponsored by Nor-Shipping.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.