US

Master Boat Builders Expands Shipbuilding Operations

[By Master Boat Builders]

Master Boat Builders, Inc. (Master Boat), an internationally recognized vessel and workboat manufacturer, today announced that it has invested $7.8 million to modernize and expand its shipbuilding operations in Mobile County by adding a new fabrication shop and floating drydock.

The expansion project creates 85 new jobs, adding to Master Boat’s skilled workforce of more than 300 workers and further contributes to Mobile County’s strength in shipbuilding and maritime services.

“This investment is about more than just expanding our ability to build more high-quality vessels. It underscores our commitment to increasing American shipbuilding capacity and we’re doing it right here along America’s Gulf Coast in Mobile County,” said Garrett Rice, President of Master Boat Builders. “By modernizing our facilities and growing our skilled workforce, we’re positioning our team to deliver critical vessels that support U.S. commerce and industry, all while training the next generation of American shipbuilders.”

“Mobile’s maritime industry continues to thrive, and Master Boat’s investment underscores our region’s leadership in shipbuilding,” said Bradley Byrne, Mobile Chamber president and CEO. “By creating new jobs, retaining existing ones and investing in workforce development, this project is a powerful example of how our business community is growing alongside our thriving port and maritime economy.”

The expansion includes the construction of a new fabrication building, a floating dry dock to support new harbor tug contracts, workforce training initiatives and infrastructure improvements.

“Master Boat Builders is a 45-year-old, third generation, locally owned shipbuilder located in the Bayou. They have employed thousands of people over that span from local communities and currently employ over 300 people. If we can’t incentivize and support the growth of a business like Master, we shouldn’t be incentivizing anyone!” said District 3 Mobile County Commissioner Randall Dueitt. “This expansion not only secures and creates jobs for local families, but it also reinforces the fact that Mobile County is a leader in shipbuilding and maritime innovation and will be for years to come.”

This project also supports the region’s ongoing workforce development and training initiatives, reflecting the growing demand for skilled talent within the maritime and shipbuilding sectors.

“Master Boat’s expansion highlights the continued momentum of Alabama’s maritime industry and reinforces Mobile County’s position as a hub for shipbuilding and repair,” said Ellen McNair, Secretary of the Alabama Department of Commerce. “This investment not only creates quality jobs but also strengthens the region’s capacity to support a vital sector of our state’s economy.”

Work on this expansion began October of 2024 and is expected to be fully operational by October of this year.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Op-Ed: MARAD Should Follow Navy's Lead to Rebuild U.S. Maritime Strength

Earlier this week, CNO Admiral Daryl Caudle and Navy Secretary John Phelan delineated their goals for the Navy - readiness, accountability, and results. They also identified clear metrics for success. The Maritime Administration and the Department of Transportation should tap the table and immediately do the same.

While serving as the Maritime Administration (MARAD) Chief Counsel during the first Obama administration, I visited the rusty Ready Reserve Force (RRF) fleet. RRF crews repeatedly asked for additional funding, an ask I conveyed to the political appointees in the Department of Transportation (DOT). Sadly, fully funding the RRF wasn't a priority for the DOT and the Office of Management and Budget leaders of the day. The same could be said about increasing the maritime workforce, or strengthening shipbuilding.

MARAD also struggled with accountability and results. This struggle stemmed from long-standing conflicting priorities between MARAD, the US Agency for International Development (USAID), and the Departments of State and Energy. MARAD advocated for US financed goods to be shipped on US owned and crewed vessels. We fought to write the Congressionally-mandated cargo preference rule. The other agencies argued for simple money transfers. MARAD lost, and the result was the undercutting of the US maritime industry.

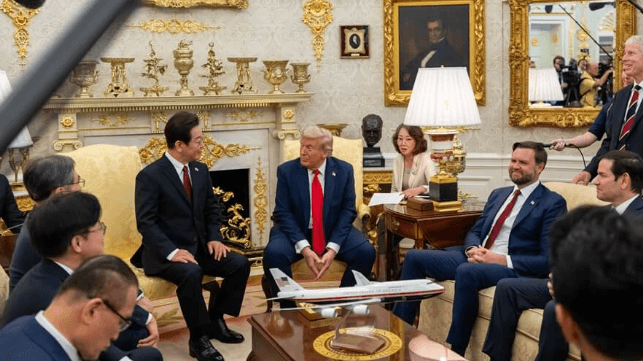

I applaud President Trump's Executive Order on April 9, 2025 entitled "Restoring America's Maritime Dominance." It is now the policy of the United States to revitalize and rebuild domestic maritime industries and workforce to promote national security and economic prosperity. It's a clear directive matched with much-needed dollars from Congress. It stops the decades long decay.

Admiral Caudle told Navy sailors and civilians that he wants to be judged by specific results at the end of his tenure, to include:

- Platforms delivered and repaired on time.

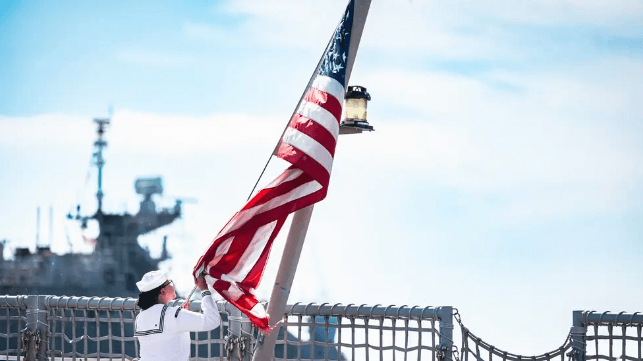

- Fully manned and combat ready ships.

- Ordnance production meeting contracted demand.

- Backlogs in repair parts eliminated.

- Sailors trained to the highest levels of mastery.

The Maritime Administration's equivalent is

- A fully functioning Ready Reserve Fleet.

- A robust merchant marine, sufficient to crew a two-front war AND regular operations.

- A thriving US shipbuilding and ship recycling industry.

- Stringent Jones Act compliance.

MARAD goals are intertwined with those set by the Navy. Both need a successful industrial base to build military and commercial ships. Success being ships built and repaired on time, on budget. Both need fully trained sailors. Both need fully manned ships. To put it bluntly, guns and butter have to move at the same time for the logistics tail in war to work.

I am encouraged by President Trump's executive order because it demonstrates top down coverage for a robust US maritime industry, something MARAD didn't have during my term in office. We fought with DOT to write the cargo preference rule and then got undercut by USAID and State. We fought to use Jones Act vessels during the 2011 Strategic Petroleum Reserve release and then got sidelined by the Department of Energy, which wanted the oil to move on foreign-flag vessels.

The Trump administration has given MARAD and DOT a once-in-a-lifetime opportunity. It's my recommendation that they seize it, match it with Secretary Phelan's directive of readiness, accountability, and results, and adopt CNO Caudle's warfighting charge to ensure the dominance of the US maritime industry and workforce.

K. Denise Rucker Krepp is a Coast Guard veteran and former chief counsel of the Maritime Administration.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.