The world is on track to run short of copper that could pose a “systemic risk” to global economic growth, driven by the energy transition and the booming artificial intelligence sector’s demand for the red metal, S&P Global said in a report on January 8

The looming deficit is forecast to reach 10mn tonnes — equivalent to almost one-third of current global demand — by 2040, in the absence of a “meaningful expansion of supply”, according to S&P Global .

“The shortage would be 23.8% shy of the projected demand of 42mn tonnes by 2040, even as recycled copper scrap more than doubles to 10mn tonnes,” according to the "Copper in the Age of AI: The Challenges of Electrification" study.

“The supply gap threatens to constrain technological advancement and economic growth as copper becomes increasingly essential for AI data centres, electric vehicles, renewable energy infrastructure and defence systems,’ the report said.

Production shortfall

Without significant changes to supply, global copper production is projected to peak at 33mn tonnes in 2030 before declining, while demand is expected to surge 50% from current levels.

“The widening disconnect highlights copper's dual role as both enabler and potential bottleneck for the energy transition and digital transformation,” S&P Global said.

Four key demand vectors are driving copper consumption higher. Core economic demand from construction, appliances and traditional industries is expected to reach 23mn tonnes by 2040, representing 53% of global demand. Energy transition demand from electric vehicles, battery storage and renewable power is projected to increase by more than 7.1mn tonnes to 15.6mn tonnes over the same period.

In addition, AI and data centre demand is expected to triple by 2040 as total installed capacity reaches 550 GW, more than five times 2022 levels, according to the study. The world’s biggest mining group BHP estimated in January that the amount of copper used in data centres worldwide will grow “sixfold by 2050”.

Another largely hidden demand factor is defence spending that could double to $6 trillion by 2040 amid rising international tensions.

Together just data centres and defence represent a combined 4mn tonnes of additional copper demand.

Demand for copper is being boosted by the construction of grid infrastructure for the green transition as well as data centres for artificial intelligence. These need between 27 and 33 tonnes of copper per megawatt of power, according to miner Grupo México, over twice the requirement of conventional data centres.

The study also identifies humanoid robots as a potential fifth demand vector; 1bn units in operation by 2040 would require about 1.6mn tonnes of copper annually, equivalent to 6% of current demand.

The study estimates that an additional 10mn tonnes of primary supply will be required by 2040 beyond increased recycling. However, without significant investment, global primary production could reach just 22mn tonnes by 2040, 1mn tonnes below current levels.

Supply side constraints

On the supply side, declining ore grades, rising energy and labour costs, complex extraction conditions and lengthy permitting processes combine to limit new mine development, the report said.

Supply chain concentration adds another layer of risk. Only six countries are responsible for roughly two-thirds of mining production, according to the study. The International Energy Agency said this year that by 2035, production from existing and planned mines was on track to meet only 70% of global demand.

Existing mines, some dating back more than a century, are getting older and less productive, while large untapped deposits are becoming harder to find. 20 mines produce about a third of the copper mined globally. Of the 239 copper deposits discovered between 1990 and 2023, only 14 were discovered in the past decade, according to the IEA.

China accounts for approximately 40% of global smelting capacity and 66% of copper concentrate imports, making the global supply vulnerable to policy shocks and trade barriers, the report said.

Analysts are expecting shortfalls as soon as this year, with consultancy Wood Mackenzie forecasting a 304,000-tonne shortfall of refined copper in 2025, a gap it says will widen in 2026. Prices have already risen to record levels in anticipation.

Prices rising

Copper is the “new gold” and has already made record gains as fears of a global shortfall mount, rising by the highest amount in over a decade

Copper soared to a record high of more than $13,000 per tonne on January 2 compared with around $8,500 two years ago, as concerns over supply disruption and tariffs extended a rally that has pushed up the price of the metal by almost a third since October, after disruptions at several large mines.

Analysts at BMI, part of Fitch Group, said they expected the price of copper to average $11,000 per tonne this year, while prices would reach $17,000 per tonne in 2034.

US President Donald Trump added to the uncertainty in December, adding copper to a list of critical minerals vital for the US economy. Fears that the Trump’s administration may impose additional import tariffs on the metal have also driven up demand The amount of copper in US Comex warehouses has jumped to a record high of more than 450,000 tonnes, compared with less than 100,000 tonnes a year ago and about 400,000 at the start of December, the Financial Times reports.

Country breakdown of the main copper producers.

Chile

· Annual copper production (2022): 5.2mn tonnes

· Proven copper reserves: 190mn tonnes (USGS estimate, 2023)

· Major companies: Codelco (state-owned), BHP, Anglo American, Antofagasta PLC, Freeport-McMoRan

Chile is the world’s largest copper producer and holds the largest proven reserves globally. State-owned miner Codelco dominates domestic output, followed by major multinational operations, including BHP’s Escondida mine — the largest copper mine in the world. Despite resource abundance, the sector has faced recent challenges, including declining ore grades, water scarcity in arid regions, labour unrest, and regulatory uncertainty linked to environmental reforms and proposed tax changes. Nonetheless, Chile remains the cornerstone of global copper supply.

Peru

· Annual copper production (2022): 2.4mn tonnes

· Proven copper reserves: 92mn tonnes

· Major companies: Southern Copper Corporation, MMG, Glencore, Freeport-McMoRan, Anglo American

Peru is the second-largest global producer of copper and has rapidly expanded its mining capacity over the past decade. The Las Bambas, Antamina, and Cerro Verde mines are among the country’s most significant operations. Copper accounts for a substantial share of Peru’s export revenue. While the government has maintained a generally investment-friendly stance, mining projects often face delays due to community opposition and social conflicts, particularly in rural Andean regions. Infrastructure and political instability continue to impact investment flows.

Democratic Republic of Congo (DRC)

· Annual copper production (2022): 2.2mn tonnes

· Proven copper reserves: 25mn tonnes

· Major companies: China Molybdenum (CMOC), Glencore, Ivanhoe Mines, Gécamines (state-owned)

The DRC has emerged as a top-three copper producer, driven by heavy Chinese investment and joint ventures with state-owned Gécamines. The Tenke Fungurume and Kamoa-Kakula complexes are among the most productive and rapidly expanding copper sites globally. While rich in high-grade deposits, the sector is hindered by governance risks, poor infrastructure, and fluctuating mining policies. Nevertheless, output continues to rise, positioning the DRC as a key supplier for future green energy demand.

China

· Annual copper production (2022): 1.8mn tonnes

· Proven copper reserves: 26mn tonnes

· Major companies: Jiangxi Copper, Tongling Nonferrous Metals, Zijin Mining, China Nonferrous Mining Corp

China is the world’s largest consumer of copper accounting for around 58% of 2025 demand and among the top five producers, although it relies heavily on imports to meet domestic demand. Copper production is concentrated in several provinces, including Jiangxi and Yunnan. State-owned firms dominate the sector, and the government continues to invest heavily in both domestic mining and overseas copper assets. Environmental regulations have tightened in recent years, leading to modernisation and consolidation in the domestic industry.

China itself only produces around 9% of the world’s mined copper, but that figure rises to around 20% after taking into account overseas projects it has ownership stakes in, according to Benchmark Mineral Intelligence. China now controls around half of copper smelting capacity worldwide. The US, by contrast, has just two operational copper smelters.

In China, the domestic build-out of smelters has been so dramatic in recent years that there is not enough copper ore to feed all the facilities globally. Miners used to pay smelters to process their ore; now it is the other way around. The prospect of new copper smelters opening outside China in the short term — something western policymakers want, in order to reduce their reliance on Beijing — is unlikely. They are expensive to build, energy-intensive to operate and run on thin profit margins.

United States

· Annual copper production (2022): 1.2mn tonnes

· Proven copper reserves: 48mn tonnes

· Major companies: Freeport-McMoRan, Rio Tinto, Grupo México (via Asarco), Capstone Copper

The US copper sector is led by Freeport-McMoRan, which operates the Morenci and Bagdad mines in Arizona. Domestic production has been relatively stable but is challenged by permitting delays, environmental opposition, and aging infrastructure. Projects such as Rio Tinto’s Resolution Copper remain stalled due to legal and community opposition. Nevertheless, the US retains significant untapped reserves and has seen renewed policy interest in critical minerals, including copper, amid supply chain and energy transition concerns.

Australia

· Annual copper production (2022): 900,000 tonnes

· Proven copper reserves: 87mn tonnes

· Major companies: BHP, Glencore, OZ Minerals (acquired by BHP), Sandfire Resources

Australia is a leading copper reserve holder, with large-scale operations such as BHP’s Olympic Dam and Glencore’s Mount Isa complex. The country benefits from a stable regulatory environment, advanced infrastructure, and strong ESG standards. In 2023, BHP completed its acquisition of OZ Minerals, consolidating control over several copper and nickel assets critical to the energy transition. While not among the top three in annual output, Australia is well-positioned for long-term supply growth.

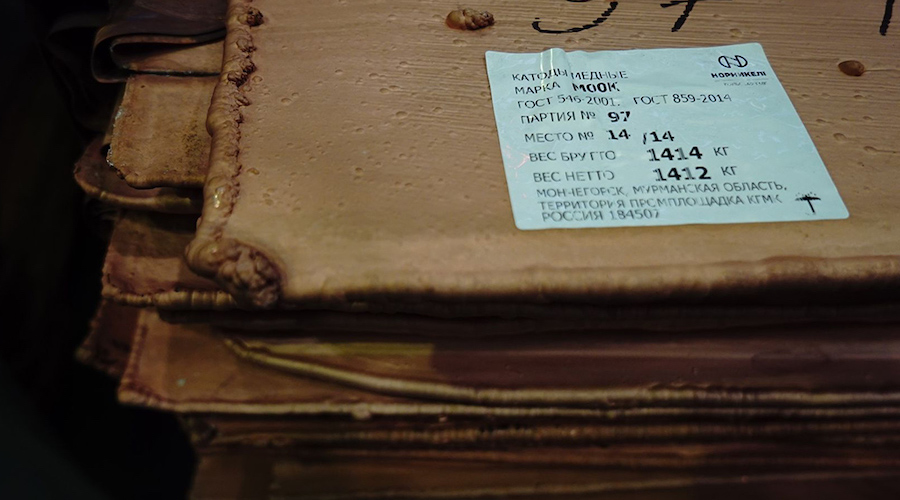

Russia

· Annual copper production (2022): 900,000 tonnes

· Proven copper reserves: 62mn tonnes

· Major companies: Norilsk Nickel, Ural Mining and Metallurgical Company (UMMC), Russian Copper Company

Russia holds large copper reserves and maintains significant domestic production, largely consumed by its own industrial base or exported to Asia. The sector is dominated by vertically integrated giants like Norilsk Nickel, which also produces palladium and nickel. Since the onset of Western sanctions in 2022, Russia has faced reduced access to equipment and capital markets, which may hinder future development and investment in the copper sector.

After more than a decade in the making, strip-mining operations began in the depths of Siberia at Udokan, one of the largest copper deposits in the world, in August 2020. As bne IntelliNews reported, the mine belongs to Alisher Usmanov, one of the richest men in Russia and contains an estimate 26.7mn tonnes of copper ore that was discovered in Soviet times, but proved technically difficult to develop thanks to its remote location in the region near Lake Baikal. Usmanov have invested some $3bn into developing the mine,

Mongolia

· Annual copper production (2022): 350,000 tonnes

· Proven copper reserves: 30mn tonnes (estimated)

· Major companies: Rio Tinto (via Turquoise Hill Resources), Erdenes Oyu Tolgoi (state-owned), Mongolyn Alt (MAK)

Mongolia is a rising copper producer with significant long-term potential, driven primarily by the massive Oyu Tolgoi mine — one of the largest known copper and gold deposits in the world. Located in the South Gobi Desert, Oyu Tolgoi is operated by Rio Tinto and co-owned with the Mongolian government through Erdenes Oyu Tolgoi. Underground development of the mine began commercial production in 2023, substantially boosting national output. Mongolia’s copper sector is strategically important due to its proximity to China, which receives the bulk of its exports. However, the country faces logistical challenges, regulatory uncertainties, and the need to balance foreign investment with national resource sovereignty. Additional deposits such as Tsagaan Suvarga and projects under MAK may further expand production in the coming decade.

Kazakhstan

· Annual copper production (2022): ~600,000 tonnes

· Proven copper reserves: ~20mn tonnes

· Major companies: Kaz Minerals, KAZ Minerals Group (formerly part of ENRC), Glencore (via Kazzinc), East Copper Company (ERG)

Kazakhstan is a significant copper producer in Central Asia, with a well-established mining sector and extensive undeveloped mineral potential. The industry is led by Kaz Minerals, which operates several large-scale open-pit mines, including Bozshakol, Aktogay, and Artemyevsky. These assets have undergone major expansion since 2015, boosting national output and positioning the company as a key supplier to China. Glencore, through its subsidiary Kazzinc, is also active in the sector, operating polymetallic mines with copper by-products.

The country’s copper sector is supported by substantial reserves and improving infrastructure, including rail and energy links to China and Europe. State-backed industrial policy has prioritised mining investment, though challenges persist around environmental regulation, water availability, and fluctuating export demand. The sector is also home to East Copper Company, part of the Eurasian Resources Group (ERG), which operates copper concentrate facilities as part of its diversified mining portfolio. Kazakhstan is considered strategically important for the global copper supply chain due to its location, resource base, and growing trade ties with China and the Eurasian Economic Union.