Engineers designing, building ventilators to aid in the fight against COVID-19

A group from Texas Tech University's Edward E. Whitacre Jr. College of Engineering is using its time to create much-needed ventilators to aid the medical community.

Texas Tech University's Edward E. Whitacre Jr. College of Engineering has formed a working group at the behest of Dean Al Sacco Jr. to design and build new ventilators to meet the needs of the COVID-19 pandemic.

For almost two weeks, a group of engineering faculty, staff and students, led by Nurcan Bac, senior associate academic dean in the College of Engineering and in partnership with regional high school students and high school engineering programs, has undertaken an effort to supply emergency respirators to health care workers on the South Plains.

"The COVID-19 pandemic has already stretched critical medical supplies to their limits and, hopefully, the ventilators the group has will be enough to provide the care needed in the coming months," Bac said. "However, if they are not, everything that can be turned into a ventilator or a respirator needs to be repurposed to serve that effort.

"In this spirit, everyone helping on the team has drawn inspiration from efforts all over the world. They have come together to generate new designs to turn anything already in a hospital not currently being used as a ventilator into a ventilator or a respirator. Right now, four designs have been developed, and two are already in the prototyping phase, being prepped for testing."

All four current designs seek to repurpose a bag valve mask (BVM), more commonly known as an artificial manual breathing unit (AMBU) bag into an automated ventilator. The first design uses a single arm to compress an AMBU bag.

The single-arm AMBU bag compression design was designed by Mazan Nachawati and a team of mechanical engineering senior design students under the direction of Jeff Hanson, a mechanical engineering instructor. This design is currently built and in the process of being prepped for stress tests to begin early next week.

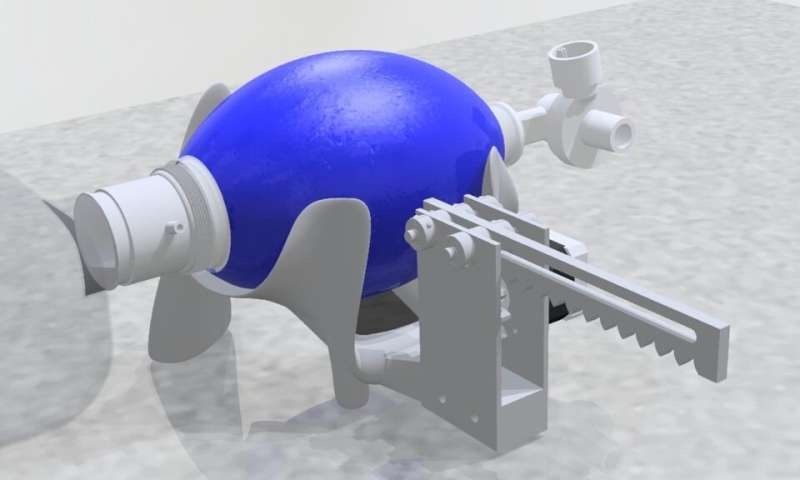

The second design involves the use of a rack and pinion gear to compress an AMBU bag. This build was designed by Hans Hudyncia and a team of mechanical engineering senior design students under Hanson's direction.

The first 3-D print of that design was just completed and is currently being constructed. The next phase for that project is to add a motor and controls, then it will be tested.

The third design uses a pressure chamber to compress an AMBU bag encased within. This project was designed by Chris O'Neal, Steven Bavousett and a team of mechanical engineering senior design students under Hanson's direction. This design is currently being fabricated and will move forward rapidly in the coming weeks.

The last design, currently referred to as the TTU AMBU-Vent, was started by Frenship High School junior Mark Dannemiller under the direction of his father, Joseph Dannemiller, assistant academic dean of the College of Engineering. This design seeks to springboard off a Massachusetts Institute of Technology design while making several changes to materials and layout.

This design is fully constructed and going through its last round of tests and software updates before undergoing stress testing.

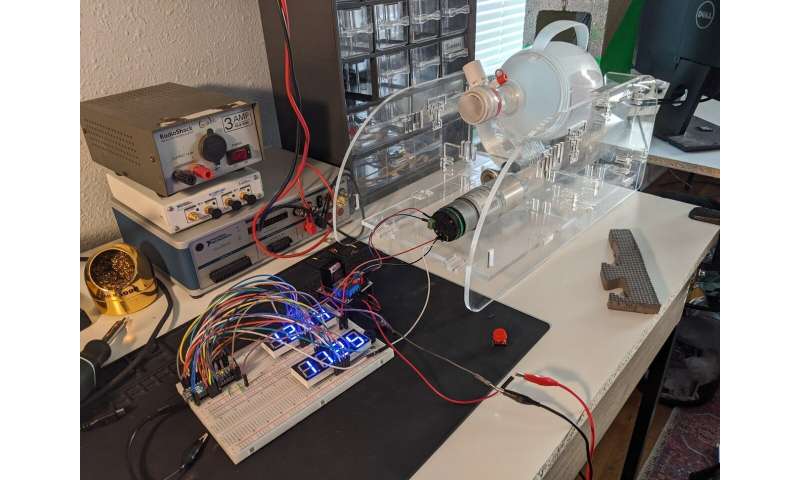

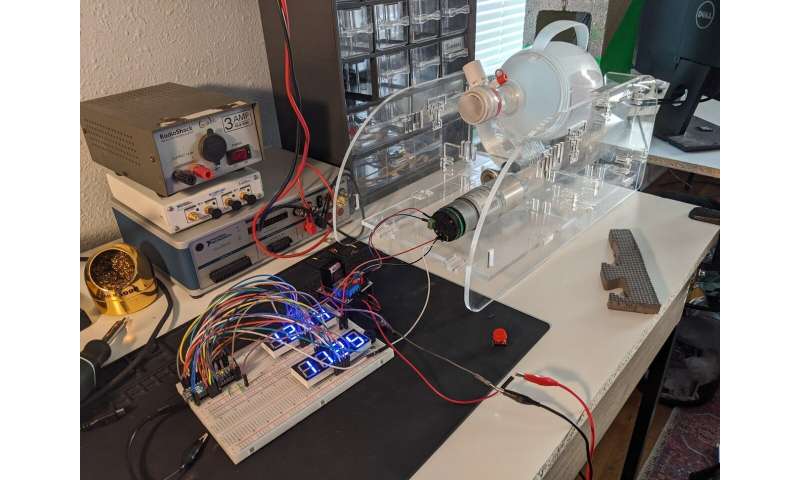

All electronics and controls for these projects are being designed by electrical and computer engineering professor Richard Gale and doctoral student Derek Johnston; mechanical engineering student Preston Abadie, Burak Aksak, associate chair, research and graduate affairs and an associate professor and Kalana Pothuvila.

All manufacturing processes and supply assessments are being coordinated by Roy Mullins and Chase George of Texas Tech's mechanical engineering shop; Michael Giesselmann, department chair and professor of electrical and computer engineering and Richard Woodcock, unit coordinator of lab support in electrical and computer engineering.

"We sincerely hope all of these efforts result in products that are not needed, but we understand that as the number of people needing non-intrusive ventilation and intrusive ventilations increases, the number of available health care workers free to assist these patients decreases," Bac said.

"These projects are a testament to the community atmosphere we have here on the South Plains and at Texas Tech. Every member of this team is giving their all, sometimes not sleeping much for days, to get those who are and will be affected all the tools they need to get through these trying times.

Provided by Texas Tech University

No comments:

Post a Comment