FROM THE FRYING PAN INTO THE FIRE

Using bacteria to convert CO2 in the air into a polyester

A team of chemical and biomolecular engineers at Korea Advanced Institute of Science and Technology has developed a scalable way to use bacteria to convert CO2 in the air into a polyester. In their paper, published in Proceedings of the National Academy of Sciences, the group describes their technique and outline its performance when tested over a several-hour period.

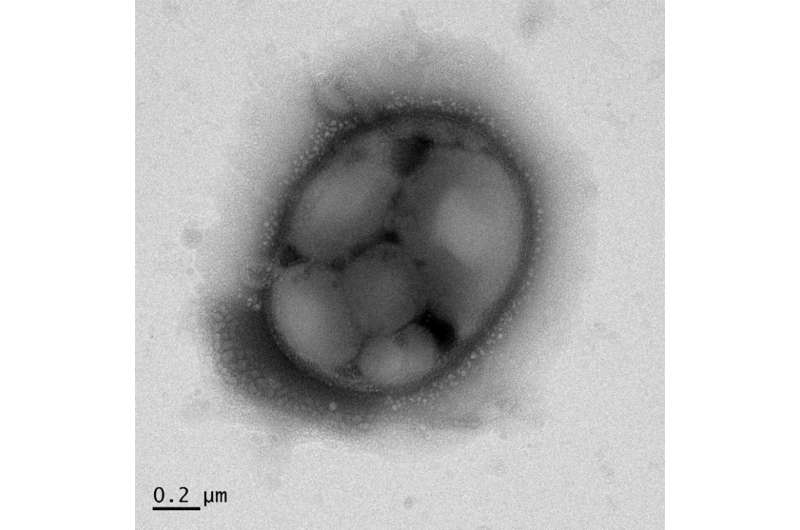

As climate change progresses, scientists around the world continue to look for ways to both prevent emissions and to scrub emissions from the air. In this new effort, the researchers took another look at the possibility of using Cupriavidus necator, a type of bacteria, to pull CO2 from the air and then to use it to make a type of polyester.

Prior research has shown that C. necator can pull in CO2 and use it to make certain types of biodegradable plastics. But the process can only be done in batches because of the need for electricity to start the process—toxic byproducts build up and kill the bacteria. This prevents the process from scaling. In this new effort, the research team in Korea overcame this problem.

The workaround involved adding a synthetic membrane at the start of the process that separates the bacteria from the toxic byproducts. This led to a two-sided process. On one side, chemical reactions prepared CO2 for fermentation, while the other side held other needed ingredients. The membrane then allowed the ingredients to flow slowly to the side with the bacteria, which used them to make bits of poly-3-hydroxybutyrate.

The research team ran the process, which involved periodically removing bacteria holding onto the PHB and adding fresh empty samples, for 18 days. They found it worked as planned and also made 11.5 mg of PHB per hour. The researchers note that the process does still require electricity but because it is so much more efficient than other methods, the cost of converting CO2 to a polyester was much cheaper. They also note that the process can be easily scaled up.

More information: Jinkyu Lim et al, Biohybrid CO 2 electrolysis for the direct synthesis of polyesters from CO 2, Proceedings of the National Academy of Sciences (2023). DOI: 10.1073/pnas.2221438120

No comments:

Post a Comment