Michelle Lewis | Mar 27 2023 -

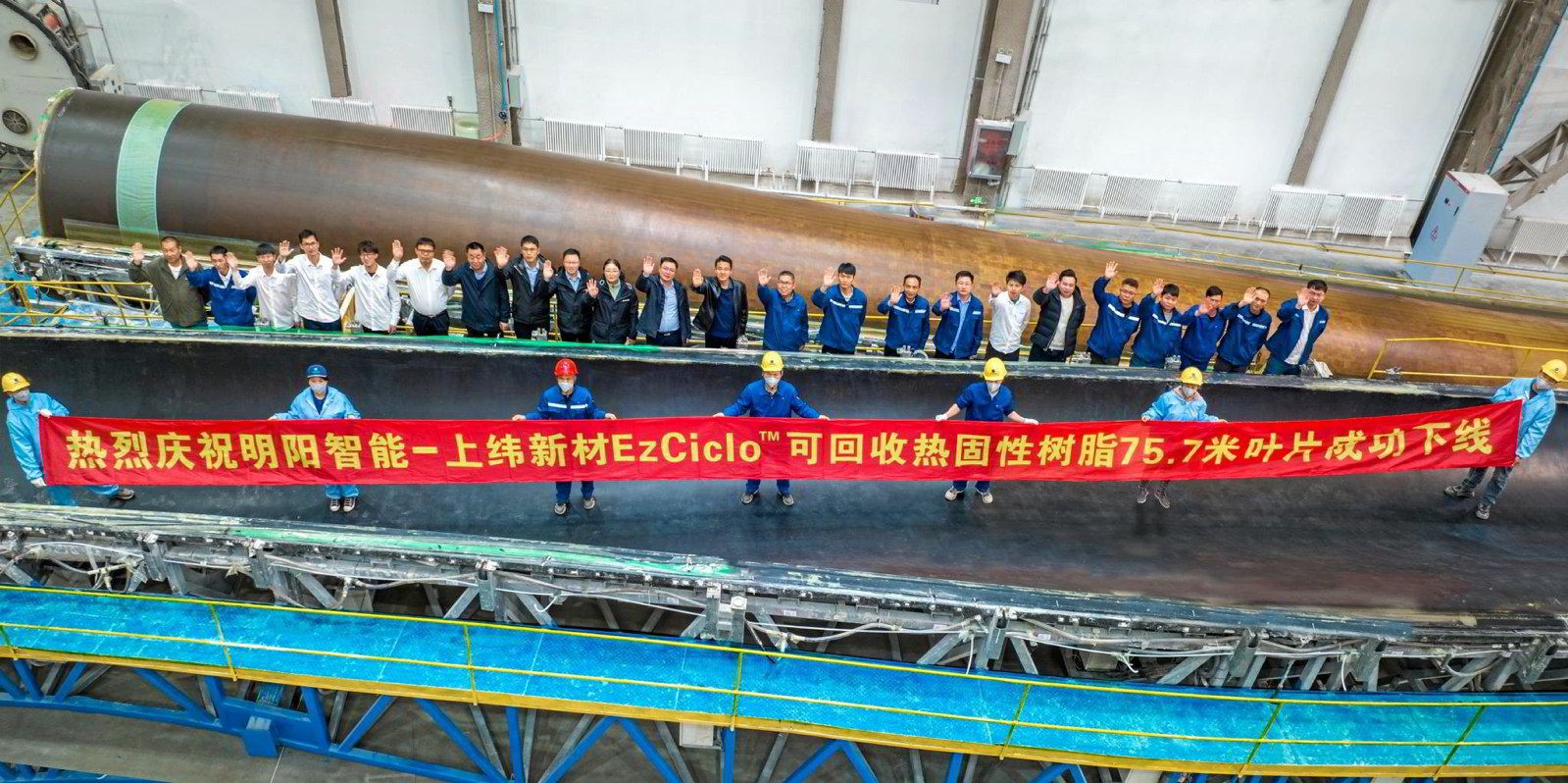

MingYang Smart Energy has launched a huge turbine blade made of over 95% recyclable materials – the first of its kind in Asia.

MingYang says it’s the “first Chinese OEM to offer recyclable blades.” Spanish-German maker Siemens Gamesa and Danish company Vestas have also launched wind turbine blade recycling schemes.

The 75.7-meter-long (248-foot-long) prototype recyclable blade was made using Taiwan-headquartered wind power material supplier Swancor’s EzCiclo recyclable thermosetting resin. It has recyclable epoxy pultrusion plates with a recyclable foam core.

EzCiclo can be recycled and degraded with Swancor’s CleaVER recycling technology, and the recycled material can be used in other industries, according to a MingYang post on LinkedIn. Swancor explains:

The wind turbine blade composite parts made of “EzCiclo” can be recycled and degraded via “CleaVER” technology in the end-of-life. The waste is turned into recycled fibers and oligomers [it’s a molecule], and the recycled fibers can be reused to [make] glass fiber or carbon fiber composites.

Zhongshan-headquartered MingYang started wind turbine production in 2007. It’s currently developing the world’s largest wind turbine with a capacity of 18 MW.

China is the world’s leading country when it comes to wind power generation. According to clean energy think tank Ember, China generated 46% more wind power than all of Europe, the world’s second-largest wind market, in 2022.

Read more: This Chinese offshore wind turbine will be able to power 90K homes

Photo: MingYang Smart Energy

MingYang Smart Energy has launched a huge turbine blade made of over 95% recyclable materials – the first of its kind in Asia.

MingYang says it’s the “first Chinese OEM to offer recyclable blades.” Spanish-German maker Siemens Gamesa and Danish company Vestas have also launched wind turbine blade recycling schemes.

The 75.7-meter-long (248-foot-long) prototype recyclable blade was made using Taiwan-headquartered wind power material supplier Swancor’s EzCiclo recyclable thermosetting resin. It has recyclable epoxy pultrusion plates with a recyclable foam core.

EzCiclo can be recycled and degraded with Swancor’s CleaVER recycling technology, and the recycled material can be used in other industries, according to a MingYang post on LinkedIn. Swancor explains:

The wind turbine blade composite parts made of “EzCiclo” can be recycled and degraded via “CleaVER” technology in the end-of-life. The waste is turned into recycled fibers and oligomers [it’s a molecule], and the recycled fibers can be reused to [make] glass fiber or carbon fiber composites.

Zhongshan-headquartered MingYang started wind turbine production in 2007. It’s currently developing the world’s largest wind turbine with a capacity of 18 MW.

China is the world’s leading country when it comes to wind power generation. According to clean energy think tank Ember, China generated 46% more wind power than all of Europe, the world’s second-largest wind market, in 2022.

Read more: This Chinese offshore wind turbine will be able to power 90K homes

Photo: MingYang Smart Energy

No comments:

Post a Comment