by Colleen MacPherson, Canadian Light Source

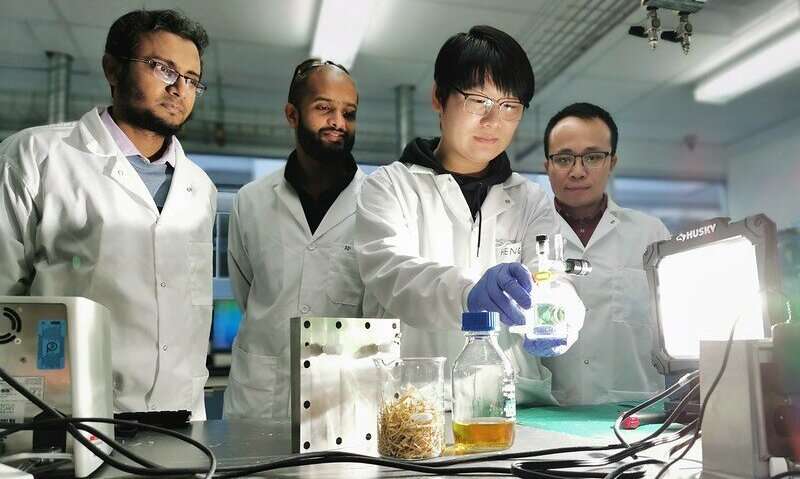

The UCalgary team is observing a photo-reactor that is being used for a photoreforming reaction with wheat straw. Left to right: Prof. Md Golam Kibria, Dr. Adnan Khan (Research Associate), Dr. Heng Zhao (Post doctoral fellow), Prof. Jinguang Hu. Credit: Prof. Hu and Kibria group

Many have dreamed of being able to turn straw into gold like the fabled Rumpelstiltskin. While this may not be possible in the literal sense, scientists are using sunlight to turn straw into something more valuable.

With the aid of technology from the Canadian Light Source (CLS) at the University of Saskatchewan, Canadian researchers have made important advances to use the power of the sun to convert biomass like wheat straw into hydrogen fuel and value-added biochemicals. This method is more efficient, eco-friendly and lucrative.

Producing energy from biomass, or plant material, has been studied for more than four decades, said Dr. Jinguang Hu, assistant professor at the University of Calgary (UCalgary). The two most common processes are thermo-chemical and biological, but these are still carbon intensive and are not economically feasible.

Dr. Hu and Dr. Md Golam Kibria, an assistant professor at UCalgary, have been focusing their recent research on an alternative approach to commonly used petro-refinery. Their novel and environmentally friendly approach called photobiorefinery uses solar energy to break down biomass, in this case wheat straw, to make green hydrogen and a high value biochemical. Canada First Research Excellence Fund (CFREF) has been supporting this research and their recent findings were published by the American Chemical Society.

One of the key aspects of an effective biomass photorefinery approach is pre-treatment of the wheat straw. Hu explained plant cell walls are made of complex and highly organized cellulose structures, a major building block of biomass. Pre-treatment of the biomass destroys those structures and exposes more of the material to the sun-driven process. Kibria added the goal was to identify a pre-treatment that does not require non-renewable resources, thereby "saving a lot of carbon and cost."

Using the CLS's Hard X-ray Micro-analysis beamline, the researchers compared how raw wheat straw and straw pre-treated in a number of ways reacted in the photorefinery. Their findings showed a phosphoric acid pre-treatment resulted in the highest production of green hydrogen and lactic acid, which is typically used for bioplastics and in food, chemical, and medical industries.

"The CLS facility allowed us to see how stable the material was at the start, during and after photorefining of wheat straw. And, we could see that in real time, which is a big advantage," said Kibria.

Another critical factor was to find an inexpensive, readily available catalyst to drive the photorefinery. The study found the best results using a low-cost photocatalyst, made from carbon and nitrogen, that is designed for visible light driven cellulose photoreforming.

"Because all biomass has a similar chemical composition, what we've shown is that you can tailor the pre-treatment and the catalyst to valorize any renewable organic material," said Hu. This finding opens up opportunities for turning straw and other plant materials into value-added green hydrogen and biochemicals.

Kibria said the next steps in the research will be to "tune the catalyst to capture more of the visible light spectrum," and then to scale up the photorefinery with an eye to eventual commercialization.

"Because biomass captures carbon dioxide from the atmosphere, we can use this process to take care of the environment and produce green hydrogen and chemicals that are economically viable," he said.

Explore further Designing water splitting catalysts using waste-yeast biomass

Many have dreamed of being able to turn straw into gold like the fabled Rumpelstiltskin. While this may not be possible in the literal sense, scientists are using sunlight to turn straw into something more valuable.

With the aid of technology from the Canadian Light Source (CLS) at the University of Saskatchewan, Canadian researchers have made important advances to use the power of the sun to convert biomass like wheat straw into hydrogen fuel and value-added biochemicals. This method is more efficient, eco-friendly and lucrative.

Producing energy from biomass, or plant material, has been studied for more than four decades, said Dr. Jinguang Hu, assistant professor at the University of Calgary (UCalgary). The two most common processes are thermo-chemical and biological, but these are still carbon intensive and are not economically feasible.

Dr. Hu and Dr. Md Golam Kibria, an assistant professor at UCalgary, have been focusing their recent research on an alternative approach to commonly used petro-refinery. Their novel and environmentally friendly approach called photobiorefinery uses solar energy to break down biomass, in this case wheat straw, to make green hydrogen and a high value biochemical. Canada First Research Excellence Fund (CFREF) has been supporting this research and their recent findings were published by the American Chemical Society.

One of the key aspects of an effective biomass photorefinery approach is pre-treatment of the wheat straw. Hu explained plant cell walls are made of complex and highly organized cellulose structures, a major building block of biomass. Pre-treatment of the biomass destroys those structures and exposes more of the material to the sun-driven process. Kibria added the goal was to identify a pre-treatment that does not require non-renewable resources, thereby "saving a lot of carbon and cost."

Using the CLS's Hard X-ray Micro-analysis beamline, the researchers compared how raw wheat straw and straw pre-treated in a number of ways reacted in the photorefinery. Their findings showed a phosphoric acid pre-treatment resulted in the highest production of green hydrogen and lactic acid, which is typically used for bioplastics and in food, chemical, and medical industries.

"The CLS facility allowed us to see how stable the material was at the start, during and after photorefining of wheat straw. And, we could see that in real time, which is a big advantage," said Kibria.

Another critical factor was to find an inexpensive, readily available catalyst to drive the photorefinery. The study found the best results using a low-cost photocatalyst, made from carbon and nitrogen, that is designed for visible light driven cellulose photoreforming.

"Because all biomass has a similar chemical composition, what we've shown is that you can tailor the pre-treatment and the catalyst to valorize any renewable organic material," said Hu. This finding opens up opportunities for turning straw and other plant materials into value-added green hydrogen and biochemicals.

Kibria said the next steps in the research will be to "tune the catalyst to capture more of the visible light spectrum," and then to scale up the photorefinery with an eye to eventual commercialization.

"Because biomass captures carbon dioxide from the atmosphere, we can use this process to take care of the environment and produce green hydrogen and chemicals that are economically viable," he said.

Explore further Designing water splitting catalysts using waste-yeast biomass

More information: Xinxing Wu et al. Sunlight-Driven Biomass Photorefinery for Coproduction of Sustainable Hydrogen and Value-Added Biochemicals, ACS Sustainable Chemistry & Engineering (2020). DOI: 10.1021/acssuschemeng.0c06282

Provided by Canadian Light Source

No comments:

Post a Comment